Production method of sandwich type paper-making method reconstructed tobacco leaf

A production method and a technology for reconstituting tobacco leaves, which are applied in the directions of papermaking, papermaking, textiles and papermaking, can solve the problems of difficulty in ensuring the uniform, consistent and stable longitudinal and lateral distribution of an intermediate core layer, and achieve full utilization of raw materials and low cost. , the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

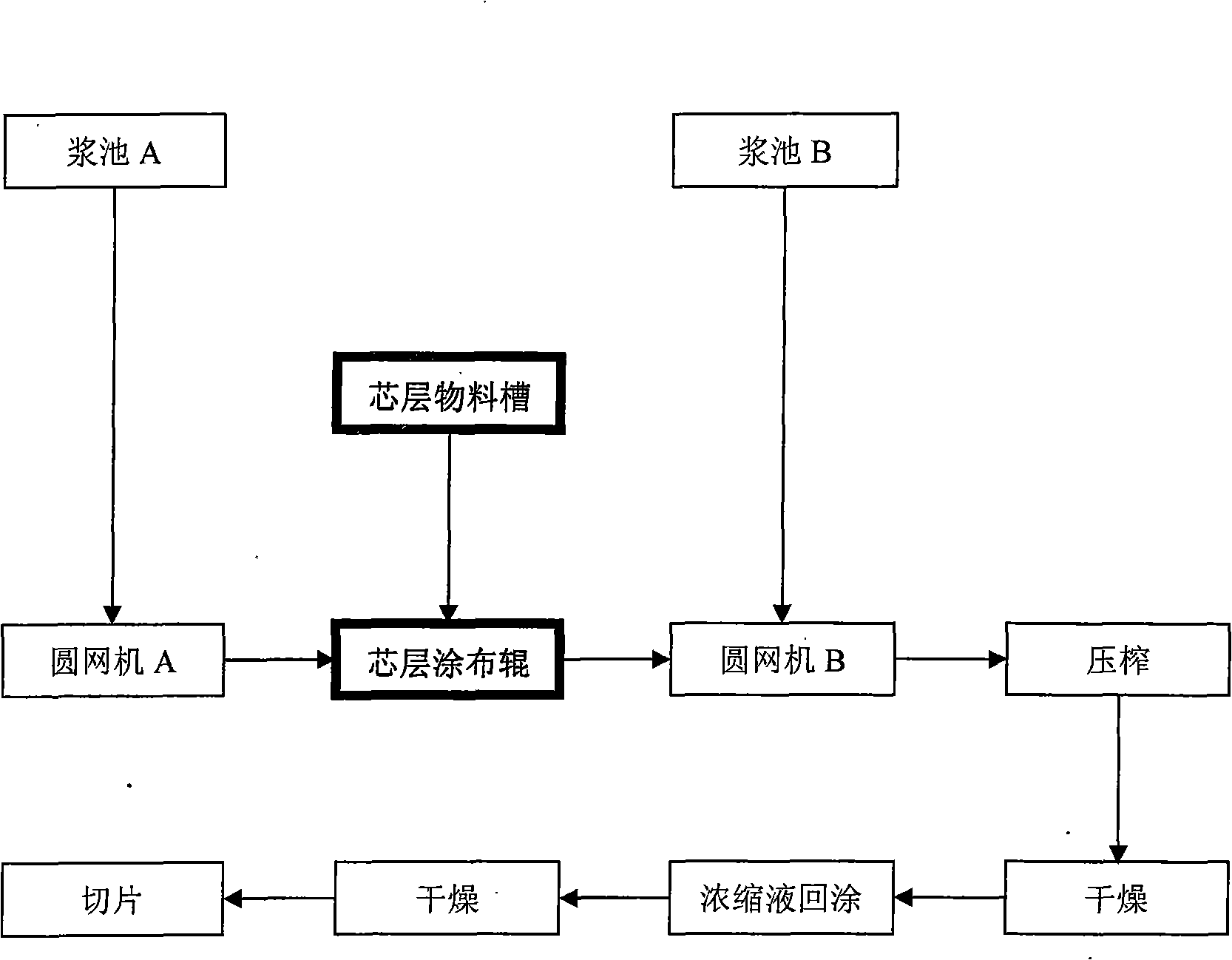

Method used

Image

Examples

Embodiment 1

[0026] Production of reconstituted tobacco leaves by sandwich papermaking method. Weigh 570kg of tobacco stems, 380kg of tobacco fragments and 50kg of coniferous wood pulp, soak and extract with 8 times the amount of 90°C water, and separate the soluble matter. The insoluble matter is beaten, and the pulp must be copied for later use. The soluble matter is concentrated in vacuum to a density of 1.1-1.2g / cm 3 The concentrate is ready for use. Weigh 100 kg of 20-mesh tobacco powder raw material, add 400 kg of clear water and stir evenly, then add 5 kg of carboxymethyl cellulose to prepare the coating material for the core layer. The prepared slurry is used to make the surface layer. Firstly, the upper layer is made, and then the coating material of the core layer is evenly applied to the upper layer by the coating roller, and then the lower layer is made on the core layer, and finally pressed into a film base. Backcoat the concentrate onto the formed sheet. After drying and ...

Embodiment 2

[0028] Repeat Example 1 with the following differences: Weigh 540 kg of tobacco stems, 360 kg of tobacco chips and 100 kg of wood pulp, soak and extract with 12 times the amount of 60° C. water. Weigh 100 kg of 40-mesh tobacco powder raw material, add 300 kg of clear water and 1 kg of Maillard reaction fragrance, stir evenly, add 5 kg of carboxymethyl cellulose, and prepare the coating material for the core layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com