Hot-filament chemical vapor deposition batch preparation method of complicated-shape diamond coated cutting tool

A diamond coating and complex shape technology, which is applied in metal material coating process, coating, gaseous chemical plating, etc., can solve coating difficulties, poor heat conduction, and unsuitable CVD diamond coating complex shape carbide tools Batch preparation equipment and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

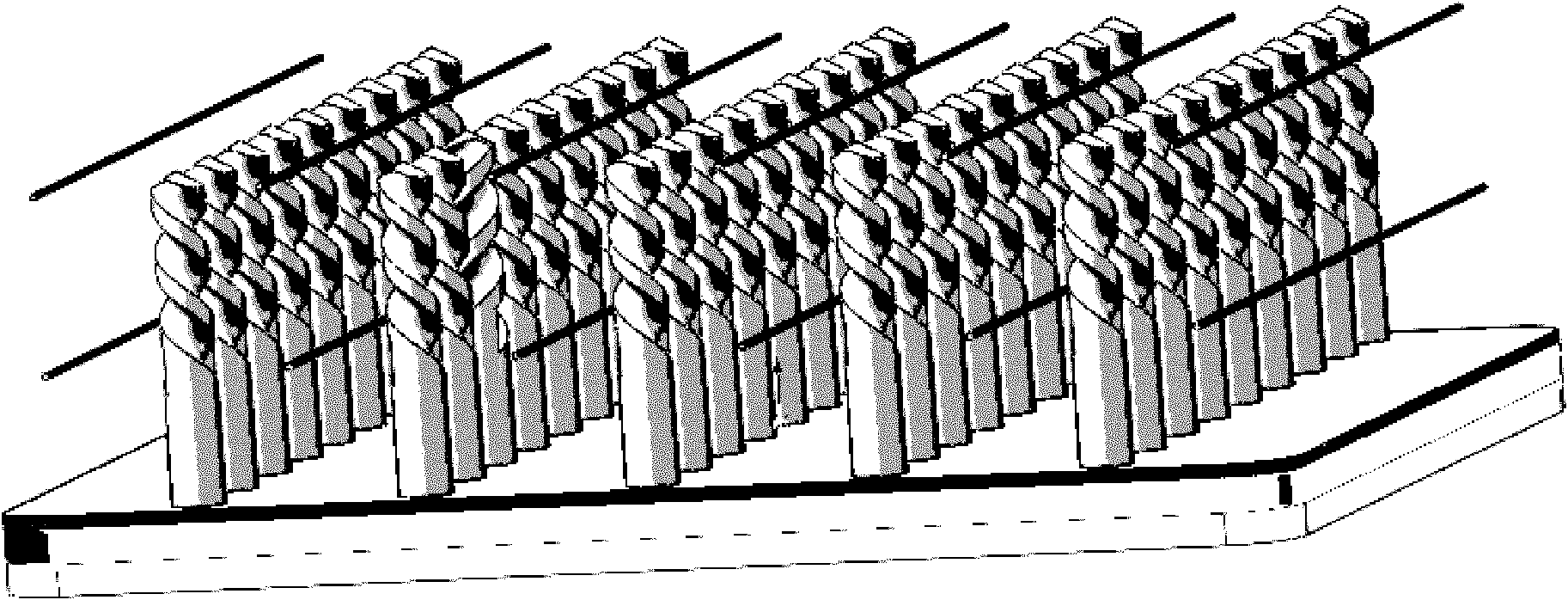

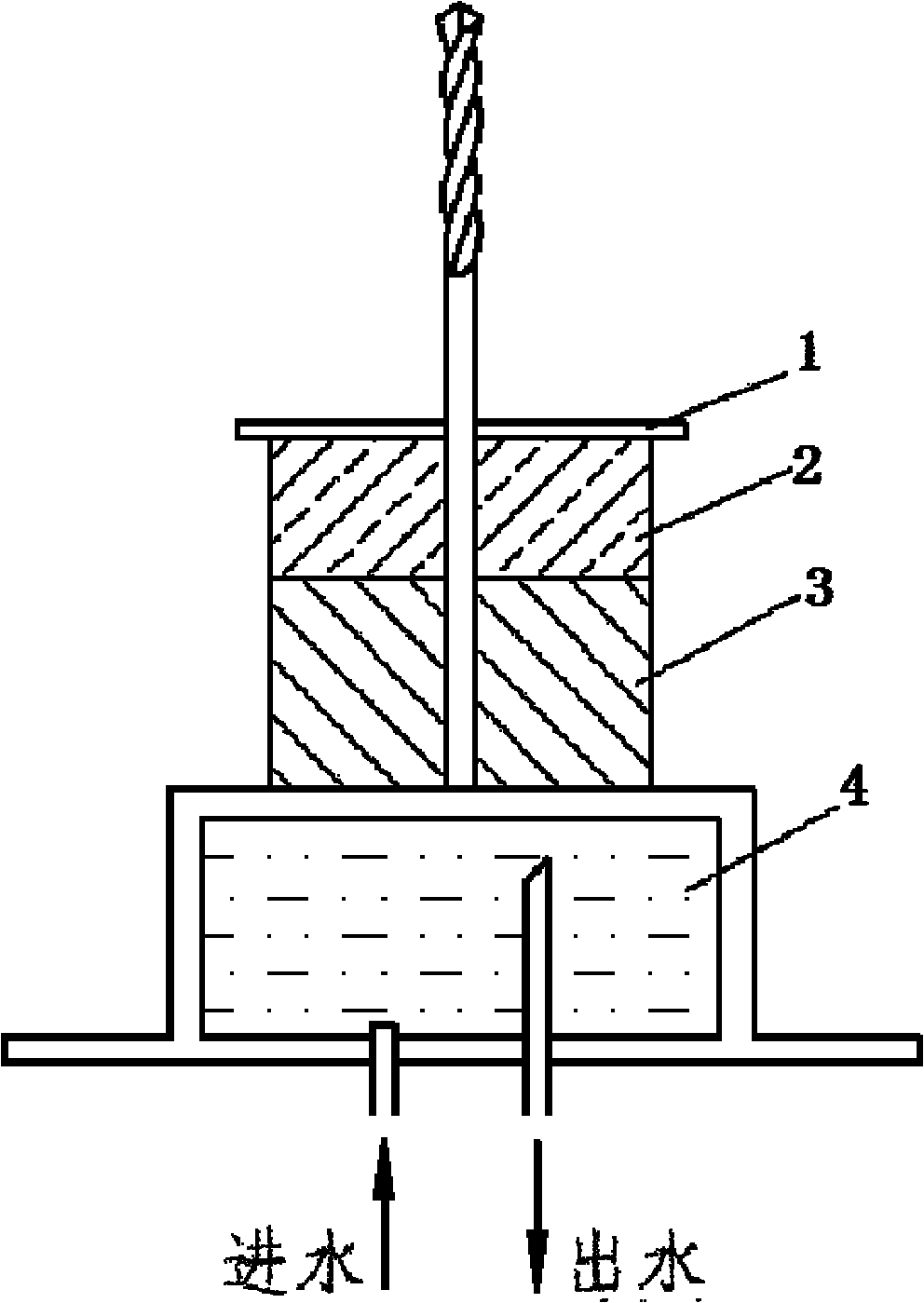

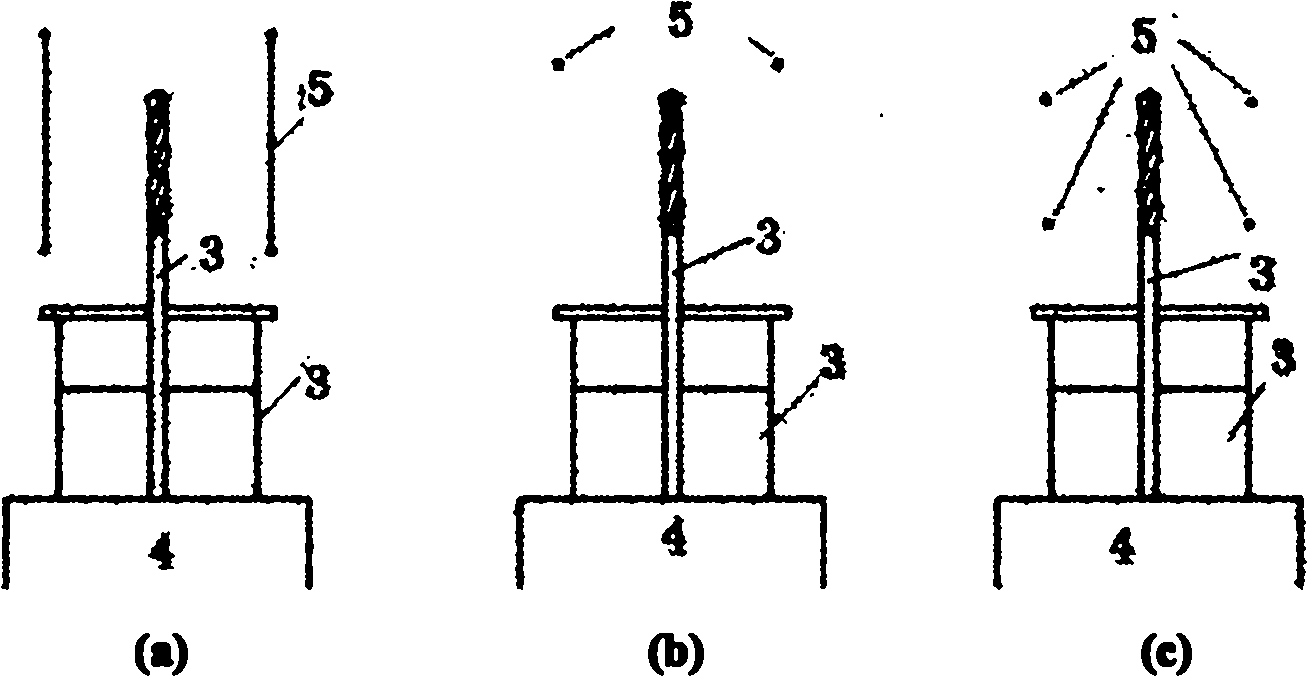

[0023] Such as figure 1 As shown, the CVD diamond coating is plated on the milling cutter for processing graphite, the diameter of the tool shank is φ4, the length of the blade is 30 mm, and the total length of the tool 5 is 100 mm. The structure of the cooling base of the sandwich cutter 5 used in this embodiment is: the copper block size is high, wide and long 30 × 30 × 100 mm, the corresponding size of graphite is 30 × 20 × 100 mm, and the thickness is a molybdenum sheet of 0.4 mm 1. Cut into 35×100mm, and drill 40 φ4.2 holes (hole depth: 40mm) at even intervals on the cooling base, so as to install and insert 40 milling cutters upright. The molybdenum sheet 1 covers the graphite block 2 to protect the graphite from being corroded by H atoms.

[0024] The first step, place the blade of the above-mentioned long handle milling cutter in Murakami agent for ultrasonic corrosion, the formula (weight ratio) of the corrosion solution: potassium ferricyanide: potassium hydroxide: ...

Embodiment 2

[0033] Plating CVD diamond coating on the milling cutter for processing graphite, the diameter of the tool shank is φ1, the length of the blade is 20mm, and the total length of the tool 5 is 50 millimeters. The structure of the cooling base of the sandwich cutter 5 used in this embodiment is: the copper block size is high, wide and long 30 × 30 × 100 mm, the corresponding size of graphite is 30 × 10 × 100 mm, and the thickness is a molybdenum sheet of 0.2 mm 1 Cut into 35×100 mm, drill 50 φ3.2 holes (hole depth 25 mm) evenly spaced on the cooling base, so as to install and insert 50 milling cutters upright.

[0034] The first step is to take 50 long-handle milling cutters mentioned above and carry out the same pretreatment as in Example 1. Insert the 50 milling cutter handles into the sandwich cooling base in 5 rows, 10 in each row, and place them on the hot wire. 5 On the water-cooled platform 4 of the CVD reaction chamber, the deposition of the diamond coating begins.

[00...

Embodiment 3

[0037] The CVD diamond coating is plated on the drill bit for processing carbon fiber reinforced composite materials. The diameter of the tool shank is φ6, the length of the blade is 35mm, and the total length of the tool 5 is 60 millimeters. The structure of the cooling base of the sandwich cutter 5 used in this embodiment is: the copper block size is high, wide, and long 30 × 30 × 100 mm, the corresponding size of graphite is 30 × 15 × 100 mm, and the thickness is a molybdenum sheet of 0.5 mm 1. Cut into 35×100 mm, and drill 35 φ6.2 holes (hole depth: 25 mm) evenly spaced on the cooling base, so as to install and insert 35 drill bits upright.

[0038] The first step is to take 35 long-handle milling cutters mentioned above, and carry out the pretreatment with Example 1. Insert 35 drill bit handles into the sandwich-type cooling base, 7 in each row, and place them in the 5CVD reaction chamber of the hot wire. On the water-cooled platform 4, the deposition of the diamond coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com