Magnetic suspension flywheel battery for sandwich-type electric car and work method thereof

A technology for electric vehicles and flywheel batteries, which is applied to electric vehicles, electric components, holding devices using magnetic attraction or thrust, etc., can solve the problems of large standby loss, large vibration noise, and large motor volume of flywheel batteries, and achieves suppression of gyroscopes. effect, no-load loss reduction, efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

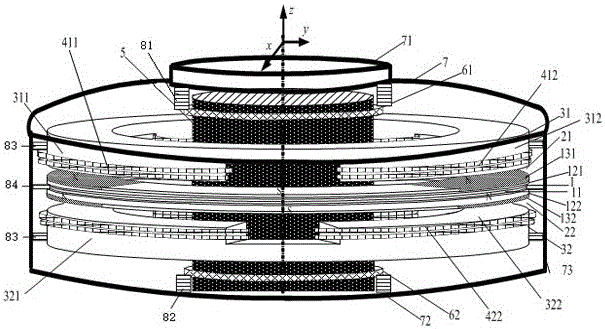

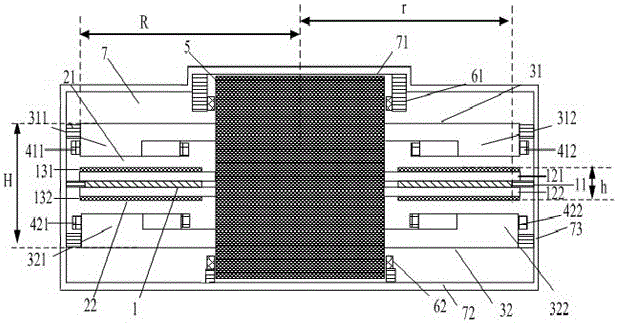

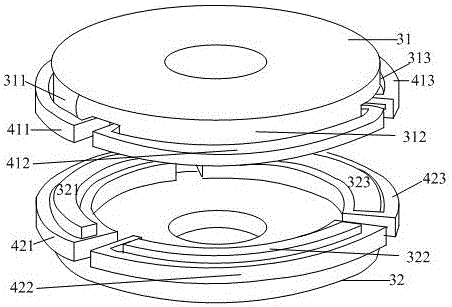

[0024] like figure 1 and figure 2 As shown, the magnetic levitation flywheel battery for sandwich type electric vehicles of the present invention has a vacuum chamber 7, and the vacuum chamber 7 is a vacuum chamber surrounded by a top end cover 71, a bottom end cover 72 and a drum 73, wherein the top of the drum 73 The center and the bottom center are respectively openings, the top central opening is sealed and fixed with a top end cover 71, and the bottom central opening is sealed and fixed with a bottom end cover 72. Inside the vacuum chamber 7, a disc-type flywheel motor 1, a vertical rotating shaft 5, and two identical disc-shaped magnetic bearings 31, 32 are arranged.

[0025] The center of the inside of the vacuum chamber 7 is a vertical shaft 5, the central axis of the vertical shaft 5 coincides with the central axis of the vacuum chamber 7, and the top of the vertical shaft 5 is coaxial with an upper protective bearing 61, and the upper protective bearing 61 is at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com