A synchronous thruster device

A technology of a propeller with the same structure, applied in the field of synchronous propeller devices, can solve the problems of high requirements on the waterproof performance of the bottom of the ship, complex structure of the propeller, difficult maintenance, etc., and achieve a strong gyroscopic effect, simple structure and low operating cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

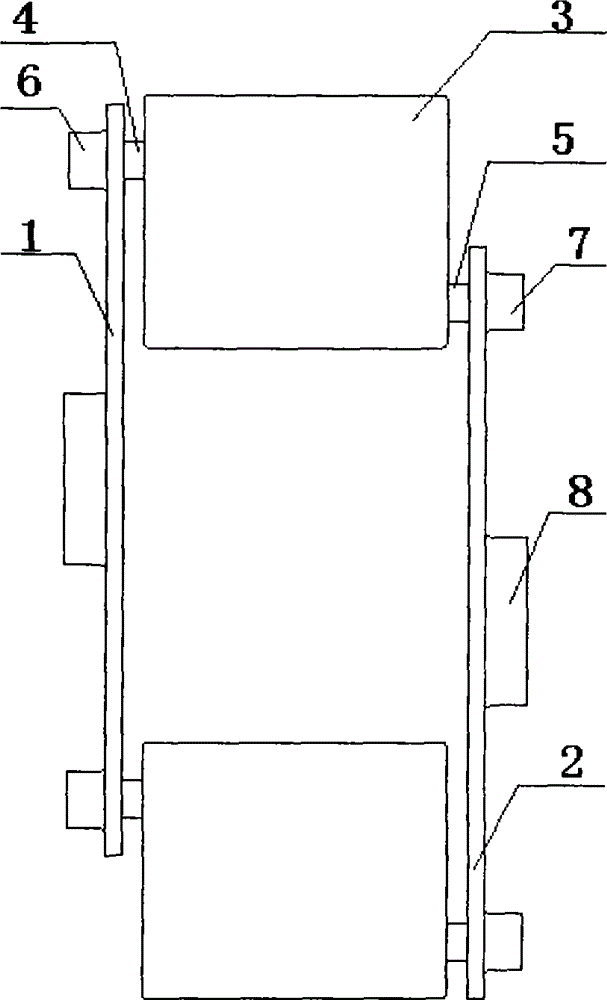

[0033] as attached figure 1 In the synchronous propeller device with two wheels and two fins shown, the upper end of the web plate 3 is connected to the upper rotating shaft 4 by clamping and welding, and the upper rotating shaft 4 is connected to the upper runner 1 by inserting the upper shaft seat 6; the web plate 3. The lower end and the lower rotating shaft 5 are also connected by clamping and welding. The lower rotating shaft 5 is connected to the lower runner 2 by inserting the lower shaft seat 7; the web plate 3 is perpendicular or parallel to the rotating shaft 8 of the runner; the upper shaft Rolling bearings are housed in the seat 6 and the lower shaft seat 7. The two rectangular fins 3 are installed symmetrically, and the connection mode is the same, and the rotating shaft 8 is connected to the power unit. The runner is made of steel plate into a square shape and fastened by flanges. The diameter of the runner is 5m, the structure of the two webs is the same, the ...

Embodiment 2

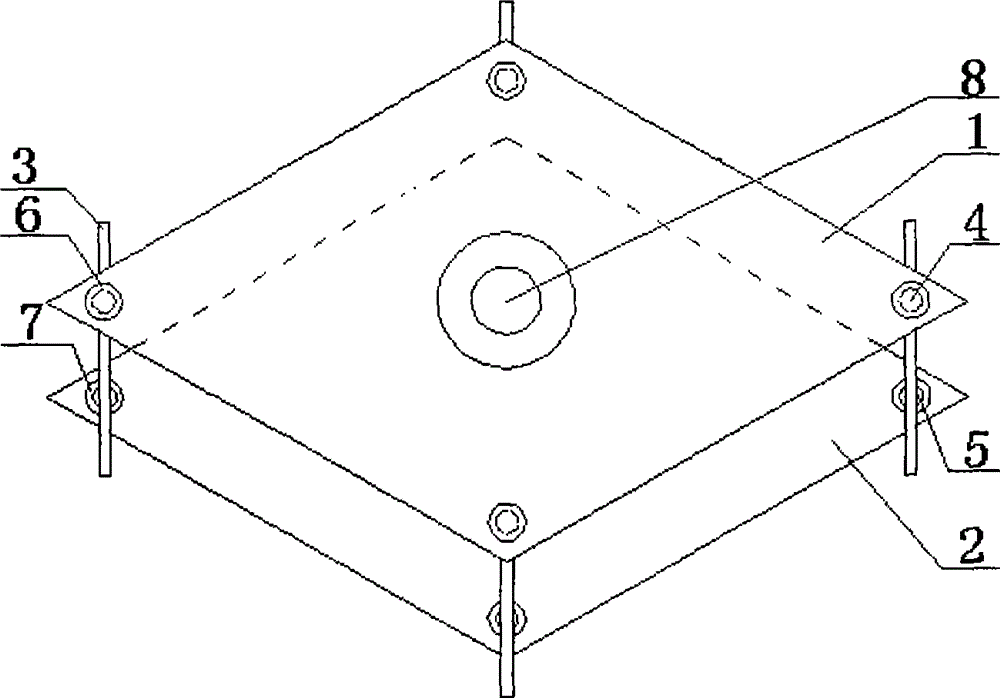

[0035] as attached figure 2 In the synchronous propeller device with two wheels and four fins shown, the upper end of the web plate 3 is connected with the upper rotating shaft 4 by clamping and welding, and the upper rotating shaft 4 is connected with the upper runner 1 by inserting the upper shaft seat 6; the web plate 3. The lower end and the lower rotating shaft 5 are also connected by clamping and welding. The lower rotating shaft 5 is connected to the lower runner 2 by inserting the lower shaft seat 7; the web plate 3 is perpendicular or parallel to the rotating shaft 8 of the runner; the upper shaft Sliding bearings are housed in the seat 6 and the lower shaft seat 7, and four web plates 3 are installed symmetrically to keep the structure of dynamic balance. The rotating shaft 8 is connected with the power unit. The runners are diamond-shaped, manufactured from steel plates and fastened by flanges.

[0036] The device is installed in the cabin of the catamaran in the...

Embodiment 3

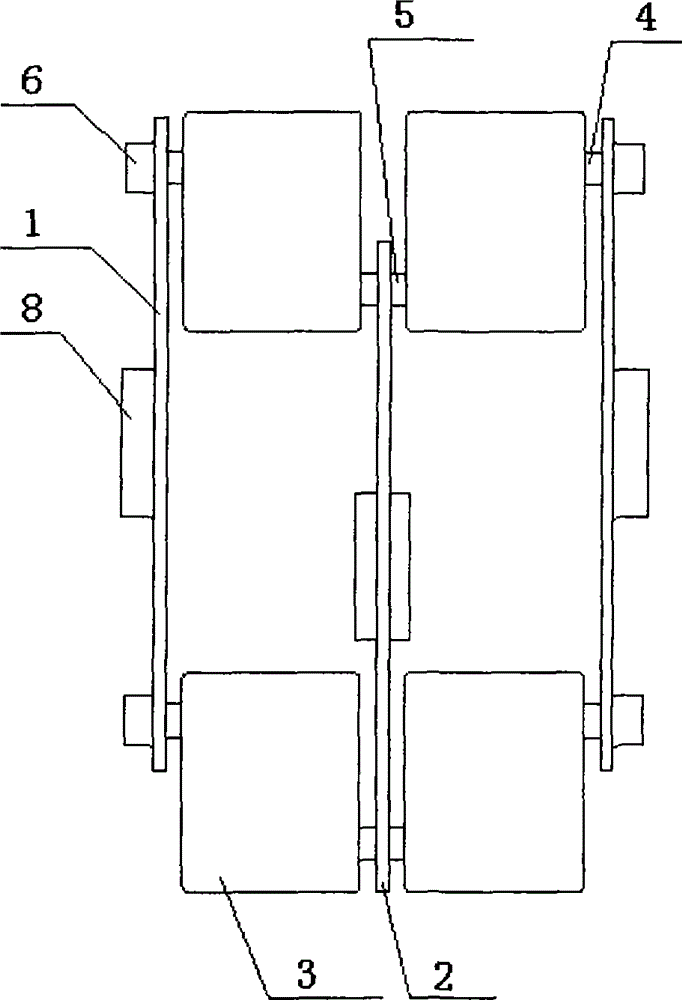

[0038] as attached image 3The semi-submerged synchronous propeller with three wheels and four fins shown has two upper runners 1 and one lower runner 2 as the propeller of this structure. The upper end of the web plate 3 is connected to the upper rotating shaft 4 by clamping and welding, and the upper rotating shaft 4 is connected to the upper runner 1 by inserting the upper shaft seat 6; the lower end of the web plate 3 and the lower rotating shaft 5 are also connected by clamping and welding Connected in a manner, the lower rotating shaft 5 is inserted into the lower shaft seat 7 and connected with the lower runner 2, the web plate 3 is perpendicular or parallel to the rotating shaft 8 of the runner, and rolling bearings or sliding bearings are housed in the upper shaft seat 6 and the lower shaft seat 7. The four fins 3 are installed symmetrically, and the installation methods are all the same, and the rotating shaft 8 is connected to the power unit. The runner is made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com