Semi-submerged propeller

A thruster and semi-submerged technology, which is applied in the direction of non-rotating propulsion elements, etc., can solve the problems of small draft hydraulic area of the web, insufficient balance of web force, poor stability, etc., and achieve a balanced distribution of force , dynamic balance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

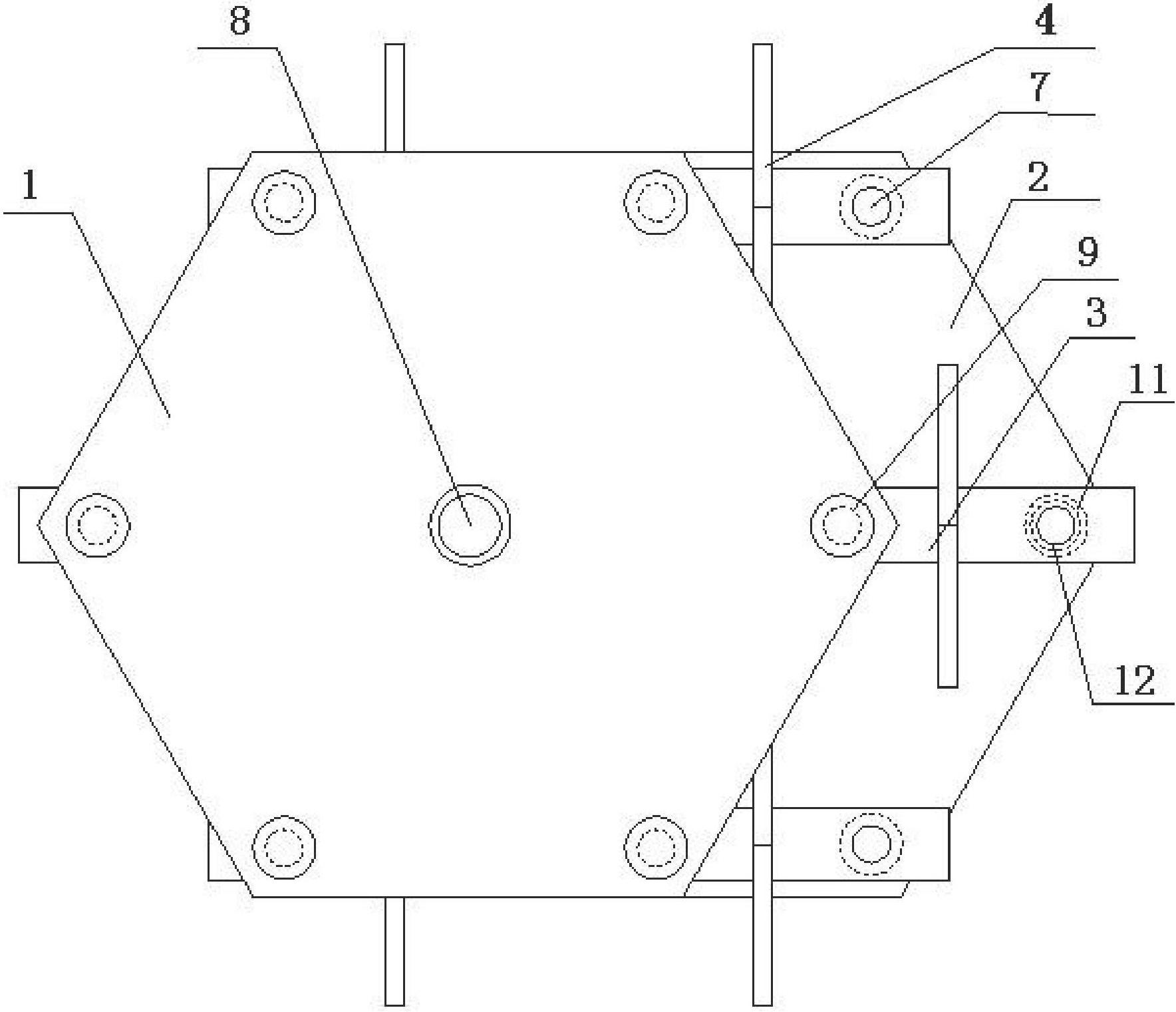

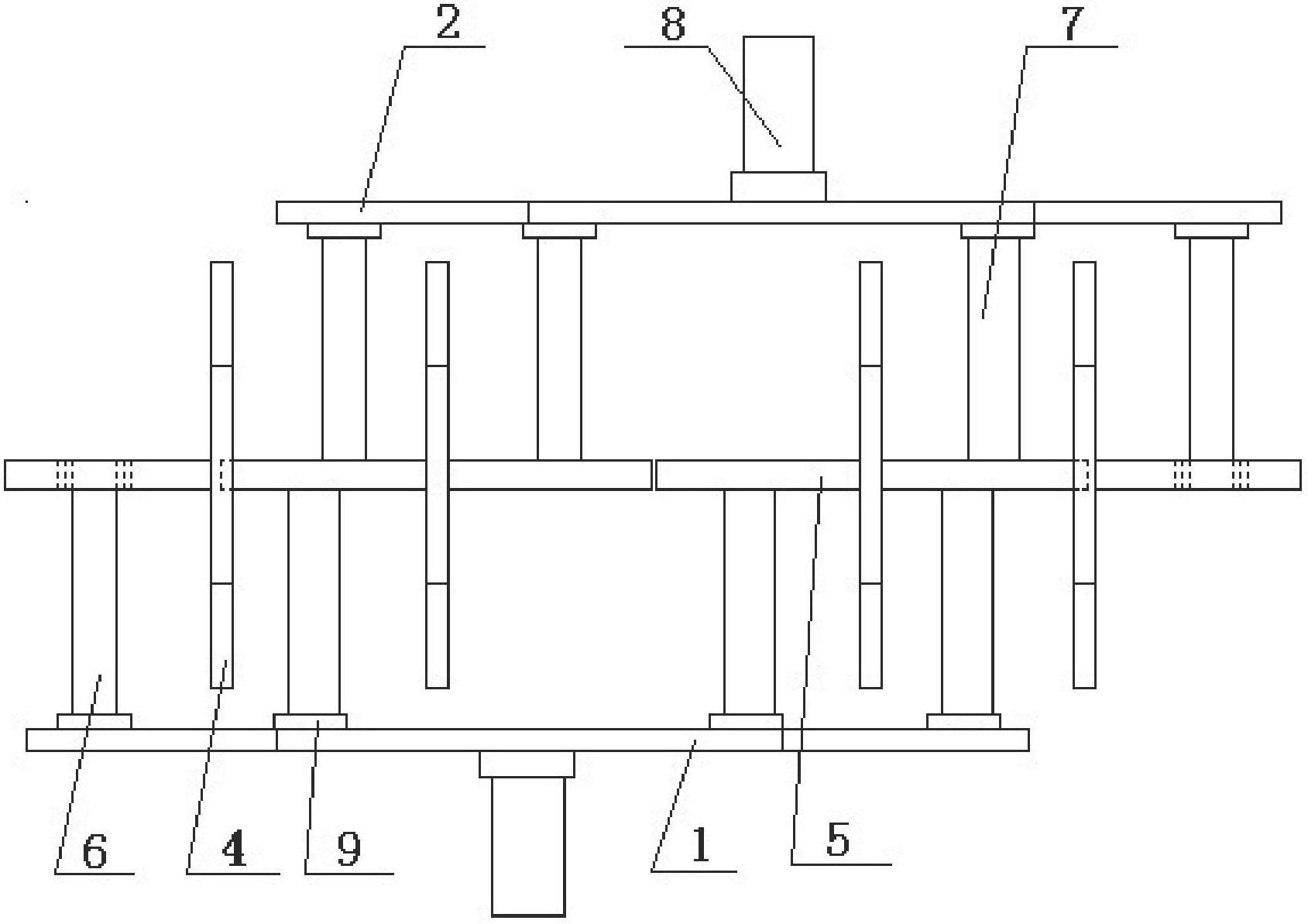

[0060] Such as figure 1 , figure 2 , image 3 with Figure 4 The semi-submerged propeller shown includes the runner a1 and the runner b2 whose axial center position of the central rotating shaft 8 is relatively staggered, and six sets of fin assembly 3 that are evenly distributed relative to the runner a1 and runner b2; The assembly 3 is composed of a web plate 4, a connecting rod 5 formed by a beam and two bearing installation holes 10 opened on the connecting rod 5. The web plate 4 is vertically installed in the middle of the connecting rod 5. The plane where the web plate 4 is located is in line with the The horizontal plane is vertical; a bearing seat 11 is installed in the bearing installation hole 10, and a bearing 12 is installed in the bearing seat 11, and the bearing 12 adopts a sliding bearing; the runner a1 is provided with a web shaft a6, and the runner a1 is embedded through the web shaft a6 The bearing 12 is connected with the web assembly 3; the web shaft b7...

Embodiment 2

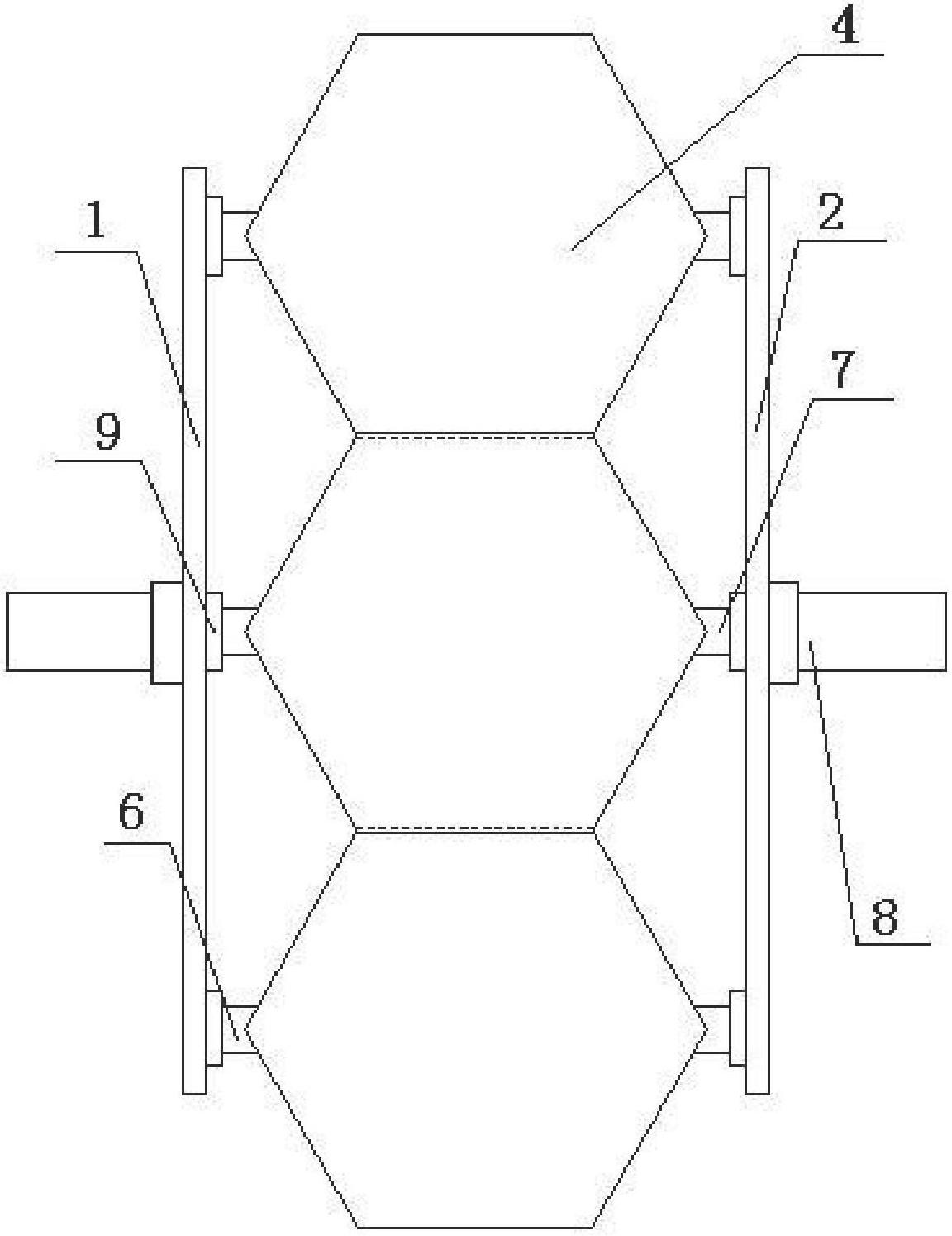

[0065] Such as Figure 5 , Image 6 with Figure 7 The semi-submerged propeller shown includes the runner a1 and the runner b2 whose axial center position of the central rotating shaft 8 is relatively staggered, and four sets of flipper assemblies 3 that are evenly distributed relative to the runner a1 and the runner b2; the flippers The assembly 3 is composed of two webs 4, a connecting rod 5 composed of a beam, and two bearing installation holes 10 opened on the connecting rod 5. The webs 4 are vertically and symmetrically installed on both sides of the connecting rod 5, forming an I-shaped structure. The plane where the web plate 4 is located is perpendicular to the horizontal plane; a bearing seat 11 is installed in the bearing mounting hole 10, and a bearing 12 is installed in the bearing seat 11, and a sliding bearing is used; the web plate rotating shaft a6 is arranged on the runner a1, and the runner a1 passes through The plate shaft a6 is embedded in the bearing 12 ...

Embodiment 3

[0069] Such as Figure 8 with Figure 9 The semi-submerged propeller shown includes the runner a1 and the runner b2 whose axial positions of the central rotating shaft 8 are relatively staggered, and two sets of fin assembly 3 that are evenly distributed relative to the runner a1 and runner b2; The assembly 3 is composed of two webs 4, a connecting rod 5 composed of a beam, and two bearing installation holes 10 opened on the connecting rod 5. The webs 4 are vertically and symmetrically installed on both sides of the connecting rod 5, forming an I-shaped structure. The plane where the webbed plate 4 is located is perpendicular to the horizontal plane; a bearing seat 11 is installed in the bearing mounting hole 10, and a bearing 12 is installed in the bearing seat 11, and a rolling bearing is used; the webbed shaft a6 is arranged on the runner a1, and the runner a1 passes through The plate shaft a6 is embedded in the bearing 12 and connected with the web assembly 3; the web sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com