Sandwich type pressure cooker

A pressure cooker and interlayer technology, applied in the field of pressure cooker, can solve problems such as difficult cleaning, single pot capacity, easy heating and oxidation of single-layer pot body, and achieve the effect of easy cleaning and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

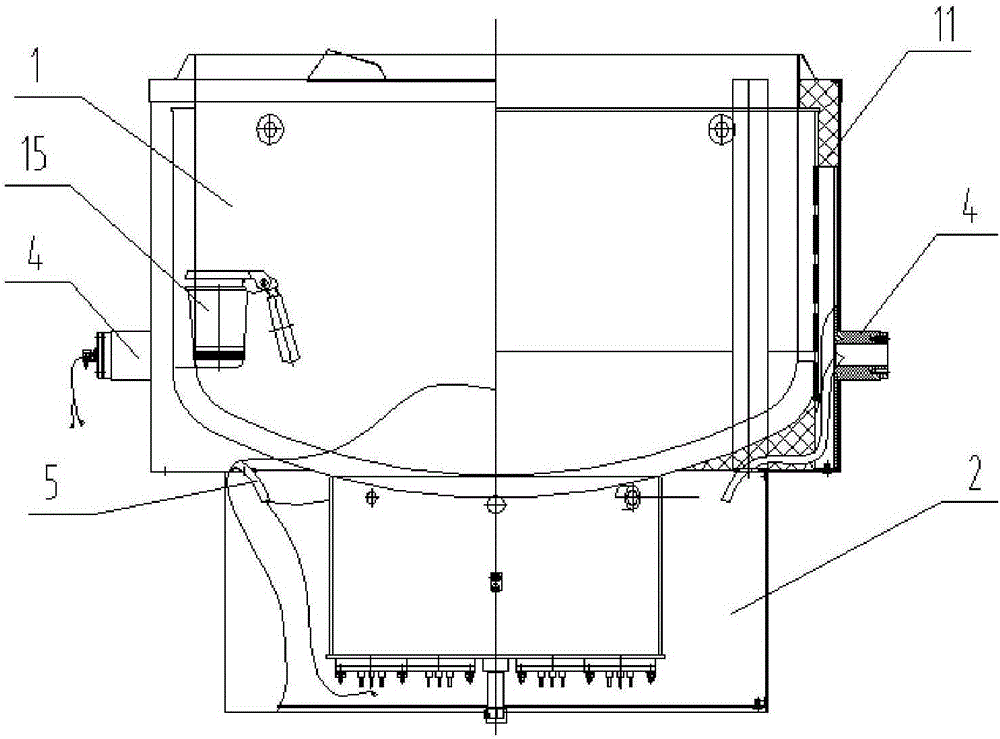

[0020] Such as figure 1 As shown, a sandwich pressure cooker includes a pot body 1; a heating box 2 is fixed at the bottom of the pot body 1. A heat insulating layer 11 is also wrapped outside the pot body 1 .

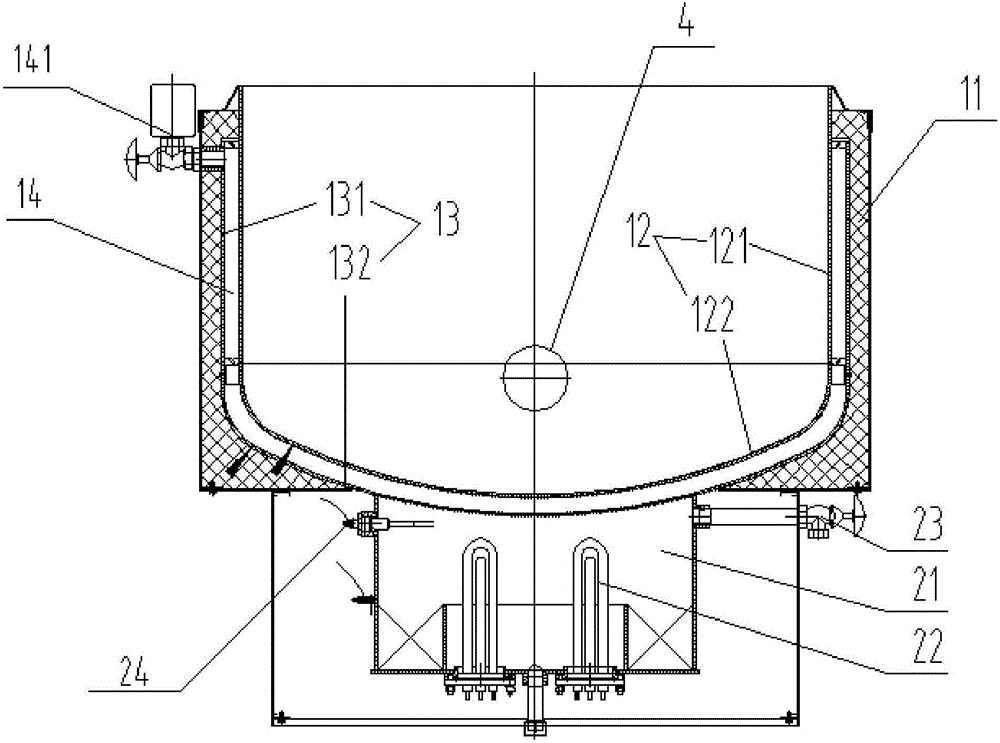

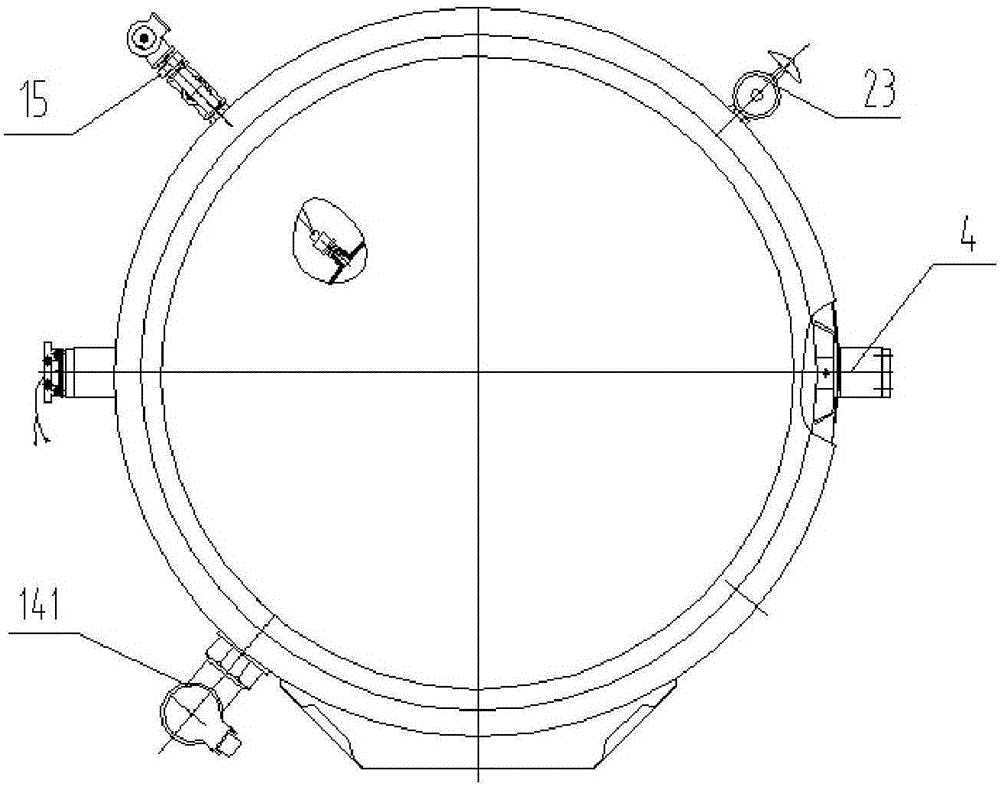

[0021] Such as figure 2 , image 3 As shown, the pot body 1 includes an inner container 12 and an outer container 13; a sealed interlayer is provided between the inner container 12 and the outer container 13 to form a steam chamber 14; the upper end of the steam chamber 14 is provided with a first water inlet; at the first water inlet There is a first water inlet valve 141 fixed there.

[0022] The heating box 2 has a heating chamber 21; the opening of the heating chamber 21 forms a sealed structure with the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com