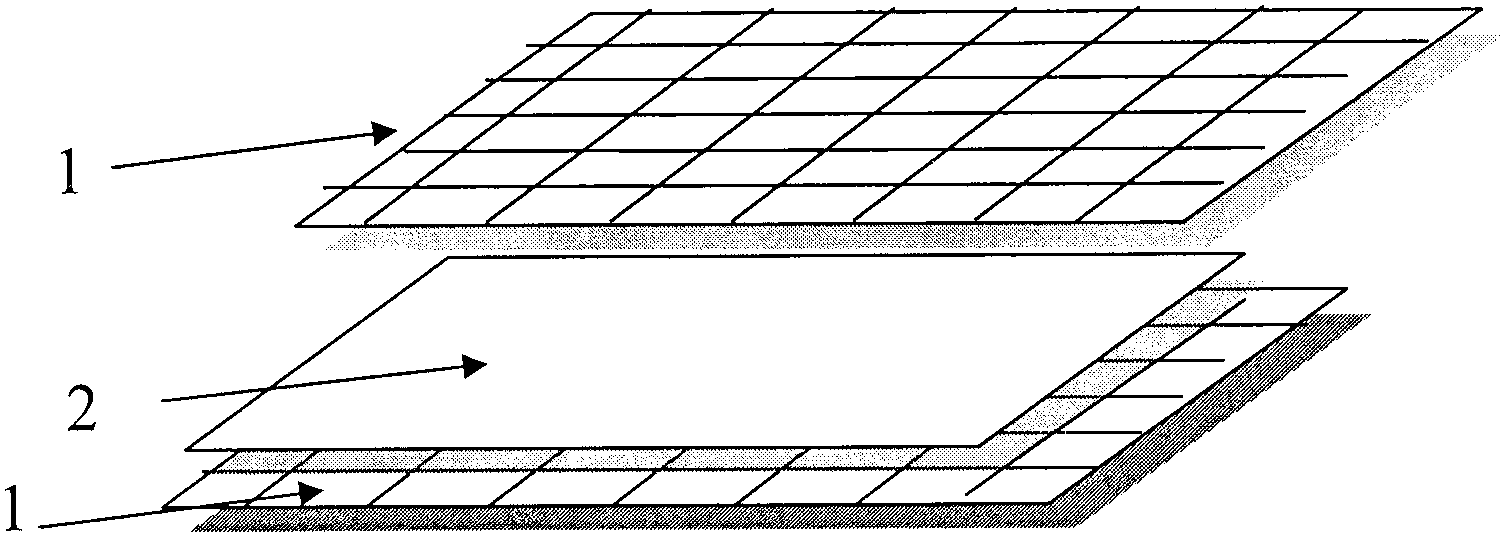

Preparation method of nanofiber sandwich type protective facial mask

A nanofiber, sandwich-type technology, applied in the field of sanitary product preparation, can solve the problems of low strength and poor filterability of non-woven fabrics, and achieve the effects of high filter cutoff, low price and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) The weighed M W =130000, cellulose diacetate chips with acetylation degree of 38% are dissolved in the mixed solution of acetone and DMAc, wherein the volume ratio of acetone and DMAc is 3:2, and it is configured as cellulose diacetate spinning with a mass fraction of 10%. solution, the spinning solution was stirred on a magnetic stirrer for 4.5 hours, and stood still for a period of time until the bubbles in the solution disappeared, which was the solution used.

[0025] (2) Inject the prepared spinning solution into the liquid storage tube of the electrospinning device, fix it on the micro-syringe pump, the inner diameter of the capillary is 0.7mm, and the electrospinning process conditions are: the voltage is 16kV, and the flow rate is 0.5ml / h , The receiving distance is 12cm.

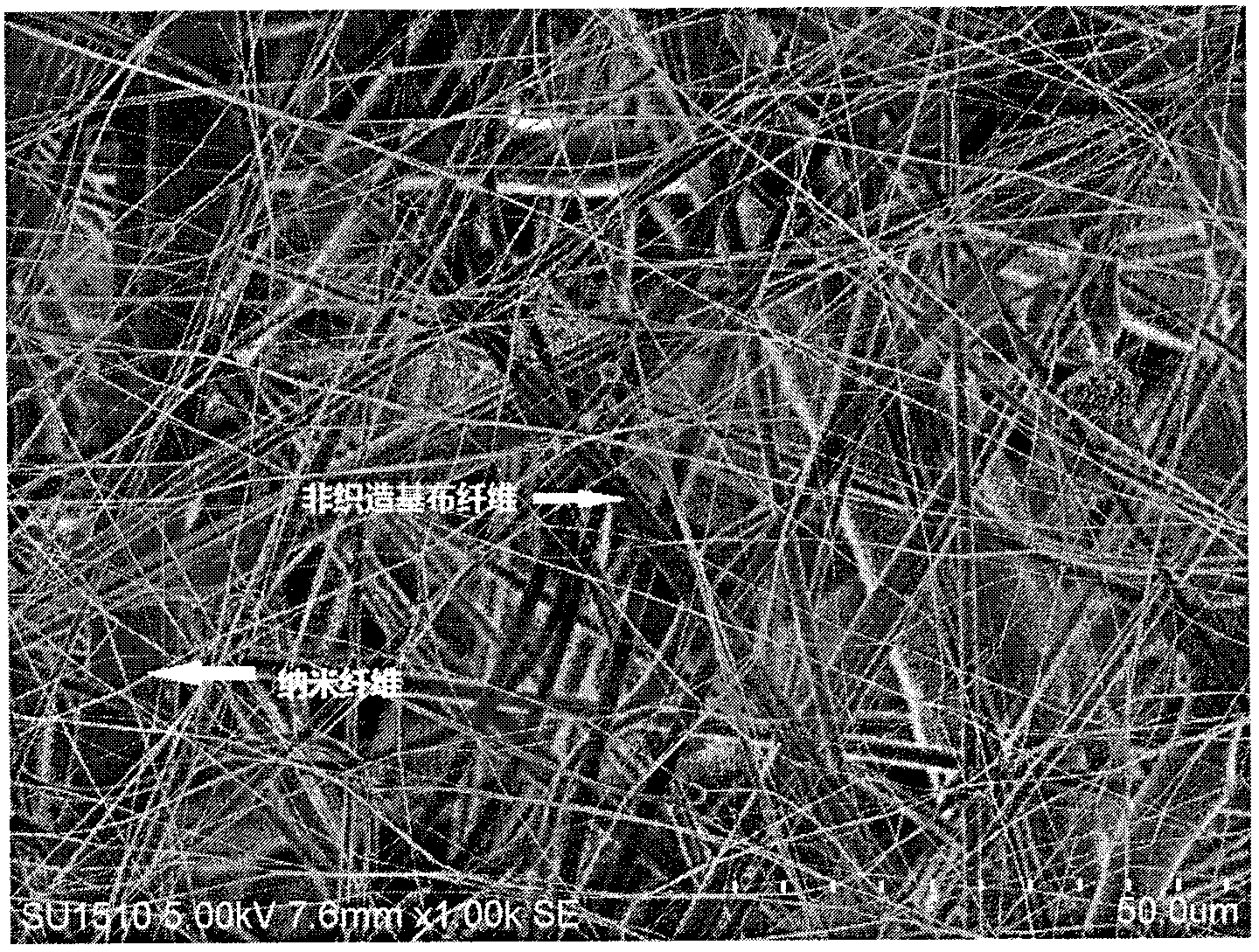

[0026] (3) Using the non-woven fabric as the acceptor, the spinning time is controlled to be 3 minutes, and the diacetate nanofiber membrane with an average diameter of 250-300 nm is obt...

Embodiment 2

[0029] (1) The weighed M W =130000, cellulose diacetate chips with acetylation degree of 38% are dissolved in the mixed solution of acetone and DMAc, wherein the volume ratio of acetone and DMAc is 3:2, and it is configured as cellulose diacetate spinning with a mass fraction of 10%. solution, the spinning solution was stirred on a magnetic stirrer for 4.5 hours, and stood still for a period of time until the bubbles in the solution disappeared, which was the solution used.

[0030] (2) Inject the prepared spinning solution into the liquid storage tube of the electrospinning device, fix it on the micro-syringe pump, the inner diameter of the capillary is 0.7mm, and the electrospinning process conditions are: the voltage is 16kV, and the flow rate is 0.5ml / h , The receiving distance is 12cm.

[0031] (3) Using the non-woven fabric as the acceptor, the spinning time is controlled to be 5 minutes, and the diacetate nanofiber membrane with an average diameter of 250-300 nm is obt...

Embodiment 3

[0034] (1) Dissolve the weighed PLA in a dichloromethane solution to prepare a spinning solution with a mass fraction of 8%, and stir the spinning solution on a magnetic stirrer for 5 hours to obtain the solution used.

[0035] (2) Inject the prepared spinning solution into the liquid storage tube of the electrospinning device, fix it on the micro-syringe pump, the inner diameter of the capillary is 0.7mm, and the electrospinning process conditions are: the voltage is 15kV, and the flow rate is 0.8ml / h , The receiving distance is 15cm.

[0036] (3) Using the non-woven fabric as the acceptor, the spinning time is controlled to be 3 minutes, and the nanofiber membrane with an average diameter of 500-600 nm is obtained by the plate collection method, and compounded with another layer of non-woven fabric to prepare a sandwich material.

[0037] (4) Carry out pore size and distribution test, air permeability and bacterial filtration efficiency and other interception performance tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com