Low temperature denitration reactor

A denitration reactor and low temperature denitration technology, applied in the field of low temperature flue gas denitrification, can solve the problems of shortening, catalyst poisoning service life, and high active temperature window, and achieve the effects of prolonging service life, simple process and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

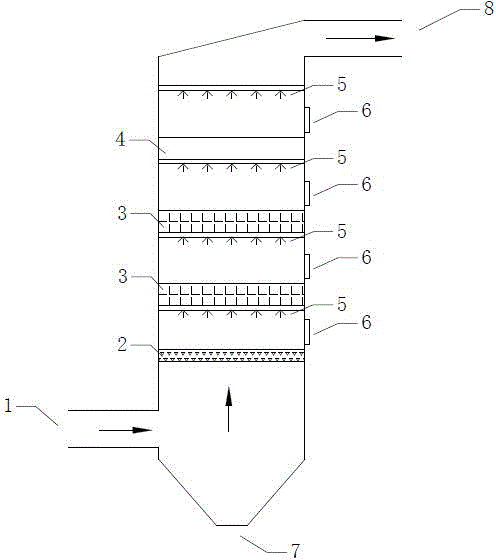

[0011] Such as figure 1 shown. The present invention comprises a rectangular parallelepiped denitrification reactor main body installed vertically, a horizontal flue gas inlet 1 is arranged on the lower side, and a horizontal flue gas outlet 8 connected to the upper port of the denitrification reactor main body is arranged on the upper side. A regeneration liquid outlet 7 is provided. The main body of the denitration reactor is equipped with a spraying device 5, a spare denitration catalyst packing grid frame, a spraying device 5, a second denitration catalyst packing grid frame, a spraying device 5, and a first denitration catalyst packing grid from top to bottom. Frame, spraying device 5 and pretreatment packing grid frame, the second denitration catalyst packing grid frame, the first denitration catalyst packing grid frame and the denitration reactor main body wall abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com