Vertical sieve plate type air purification device

A technology of air purification device and vertical sieve plate, which is applied in the direction of combination device, gas treatment, chemical instrument and method, etc. It can solve the problems of long decomposition time, hazard of odor components, difficulty in deodorization, etc., and achieve the contact between air bubbles and liquid Large area, wide range of shape selection, and accelerated compound removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

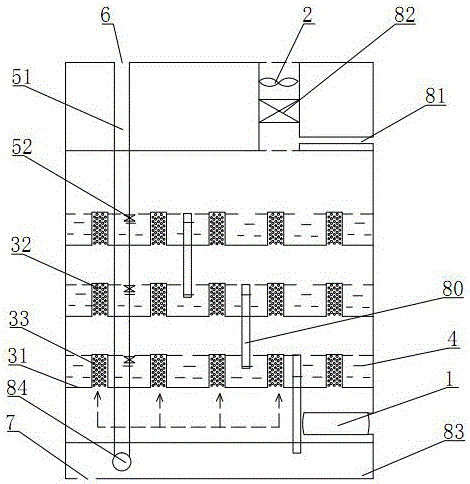

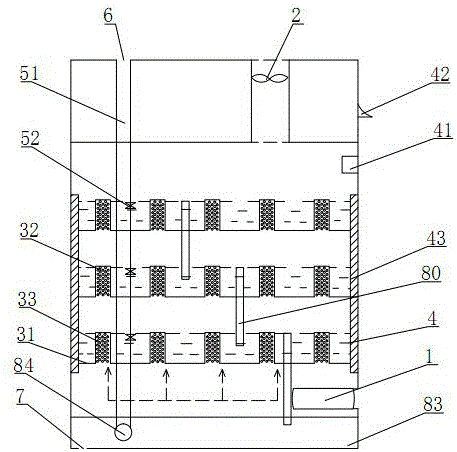

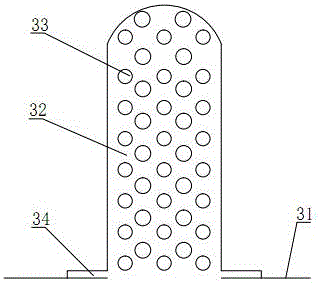

[0051] The difference between this embodiment and embodiment 1 is: as figure 2 and image 3 As shown, the sieve cap 32 is connected to the support plate 31 through several lugs 34 extending outward from the bottom edge of the sieve cap 32 , and the sieve cap 32 has an arc top or a pointed top. The diameter of the pores 33 is 0.11-0.4mm, the distance between the pores 33 is 0.5-1.0mm, the distribution of the pores 33 is a staggered design, and the opening ratio of the pores 33 is 85-90%.

[0052] The backwashing device is a backwashing device in the form of vibration, including a buzzer vibrator 41 arranged inside the purifier body, a vibration switch 42 connected with the vibrator 41, and all support plates 31 and the inner contact wall of the purifier body are provided with The buffer layer 43 made of rubber or polyethylene is connected to the vibration switch 42, and the vibrator 41 drives the purifier body to shake left and right to realize the level fluctuation of the pu...

Embodiment 3

[0054] The difference between this embodiment and Embodiment 1 is: the motor is a two-way motor, the function of adding purification liquid is realized when the motor is rotating forward, and the function of backwashing is realized when the motor is reversed. The liquid return ports of the vertical sieve plates of each layer can remove the impurities accumulated in the pores 33 through the self-circulating flow of the purification liquid 4 inside the purifier body.

Embodiment 4

[0056] The difference between this embodiment and Embodiment 1 is: the diameter of the air holes 33 is 0.5-0.78 mm, the distance between the air holes 33 is 1.1-1.6 mm, and the opening ratio of the air holes 33 is 88%.

[0057] The purification solution 4 is mixed according to the following raw materials in parts by weight: nano titanium dioxide: 5 parts, nano silicon dioxide: 2 parts, nano zirconium dioxide: 3 parts, nano silver particles 2 parts, melamine: 8 parts, polyethylene Glycol: 20 parts, sodium chloride: 8 parts, polyoxyethylene: 18 parts, plant extract 1.8 parts, water: 70 parts.

[0058] The particle size of nano-titanium dioxide is 15 nanometers, the particle size of nano-silica is 10 nanometers, the particle size of nano-zirconia is 12 nanometers, the particle size of nano-silver particles is 45 nanometers, the water is deionized water, plant extracts It is a mixture of five kinds of cactus extract, lemon extract, aloe extract, peppermint extract and wormwood ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com