Carbon nitride nanosheet-based photocatalytic composite membrane and preparation method and application thereof

A technology of nanosheet and composite film, applied in the field of g-C3N4 nanosheet-based photocatalytic composite film and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

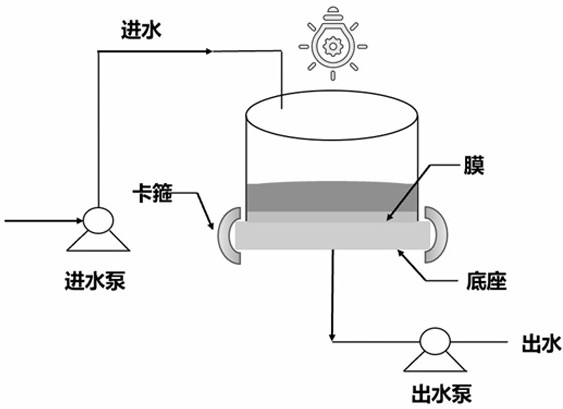

Method used

Image

Examples

Embodiment 1

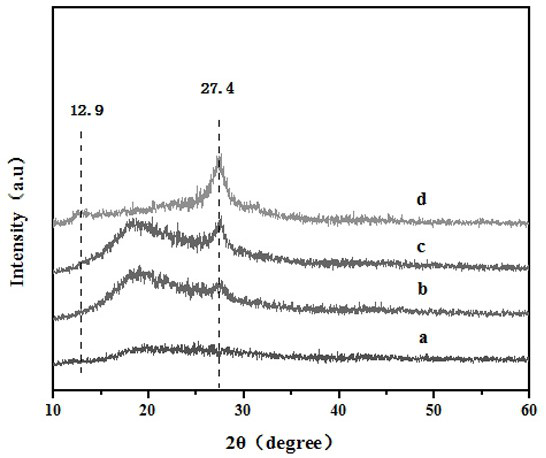

[0030] Take 0.6g of g-C 3 N 4 Nanosheets, added to 20g of N-methylpyrrolidone, ultrasonicated and stirred to obtain g-C 3 N 4 nanosheet dispersion. Add 5.4 g of CMPES to the above g-C 3 N 4 In the nanosheet dispersion, g-C is obtained by ultrasonication and stirring 3 N 4 Composite membrane liquid with a mass ratio of nanosheets to CMPES of 1:9. Pour the composite membrane solution on a clean glass plate, use a scraper to form a film layer with a thickness of 150 μm, and then immerse the glass plate in deionized water to remove the solvent to form g-C 3 N 4 Nanosheet-based photocatalytic composite film.

[0031] 1. Photocatalytic self-cleaning performance test

[0032] Adopt HP4750 ultrafiltration device to the g-C prepared by the present embodiment 3 N 4 The nanosheet-based photocatalytic composite film was tested for BSA anti-pollution. The experimental condition is normal temperature, and the BSA solution with a concentration of 200ppm is used to test the anti-...

Embodiment 2

[0042] Take 1.8g of g-C 3 N 4 Nanosheets, added to 25g of N-methylpyrrolidone, ultrasonicated and stirred to obtain g-C 3 N 4 nanosheet dispersion. Add 4.2 g of CMPES to the above g-C 3 N 4 In the nanosheet dispersion, g-C is obtained by ultrasonication and stirring 3 N 4 Composite membrane liquid with a mass ratio of nanosheets to CMPES of 3:7. Pour the composite membrane solution on a clean glass plate, use a scraper to form a film layer with a thickness of 150 μm, and then immerse the glass plate in deionized water to remove the solvent to form g-C 3 N 4 Nanosheet-based photocatalytic composite film.

[0043] 1. The photocatalytic self-cleaning performance test operation is the same as that in Example 1.

[0044] The results show that the g-C prepared in this example 3 N 4 The pure water flux of the nanosheet-based photocatalytic composite membrane is 259L / m 2 hbar, water flux to BSA solution 15 L / m 2 hbar, the rejection rate of BSA was 80.67%. After cleaning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com