Sandwich type frame saw tool bit and manufacturing method thereof

A sandwich type, manufacturing method technology, applied in the direction of manufacturing tools, stone processing equipment, stone processing tools, etc., can solve the problems of increasing the load of the gang saw, affecting the quality of processing, and dispersing the cutting force, so as to improve the orientation and improve the Quality, sharpness retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

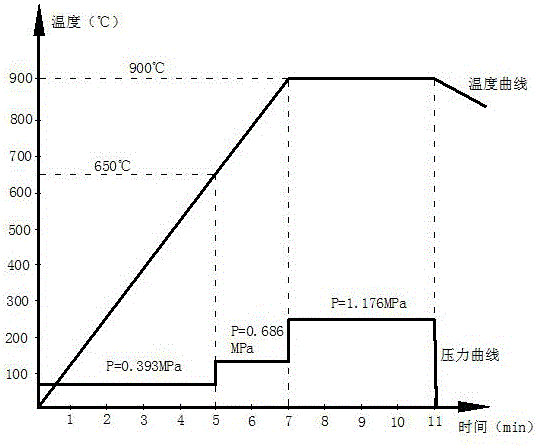

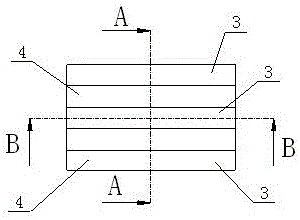

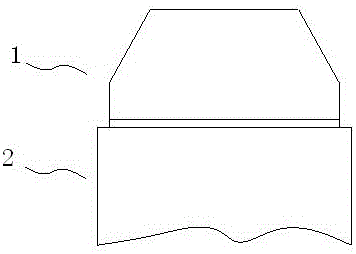

[0033] As shown in the figure, the sandwich-type gang saw head of this embodiment is provided with a cutting part 1 formed by mixing and sintering diamond powder and functional metal powder. The key point is that the cutting part 1 includes three working layers 3 and two sides A transition layer 4, between two adjacent working layers 3 is a transition layer 4, and the two sides of the sandwich type gang saw head are respectively working layers 3; the hardness of the working layer 3 is greater than the hardness of the transition layer 4; in the working layer 3 The particle size of the diamond powder in the transition layer 4 is smaller than that of the diamond powder in the transition layer 4, and the concentration of the diamond powder in the working layer 3 is greater than the concentration of the diamond powder in the transition layer 4.

[0034] like figure 2 As shown, the section of the cutting part 1 parallel to the extending direction of the working layer and the transi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com