Automatic assembly line of plastic trays

A technology for plastic pallets and assembly lines, which is applied in the field of automatic assembly lines for plastic pallets, can solve the problems of different specifications of plastic pallets, easy to make mistakes, and high labor intensity, so as to reduce the labor intensity of workers, realize the automation of production and assembly, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

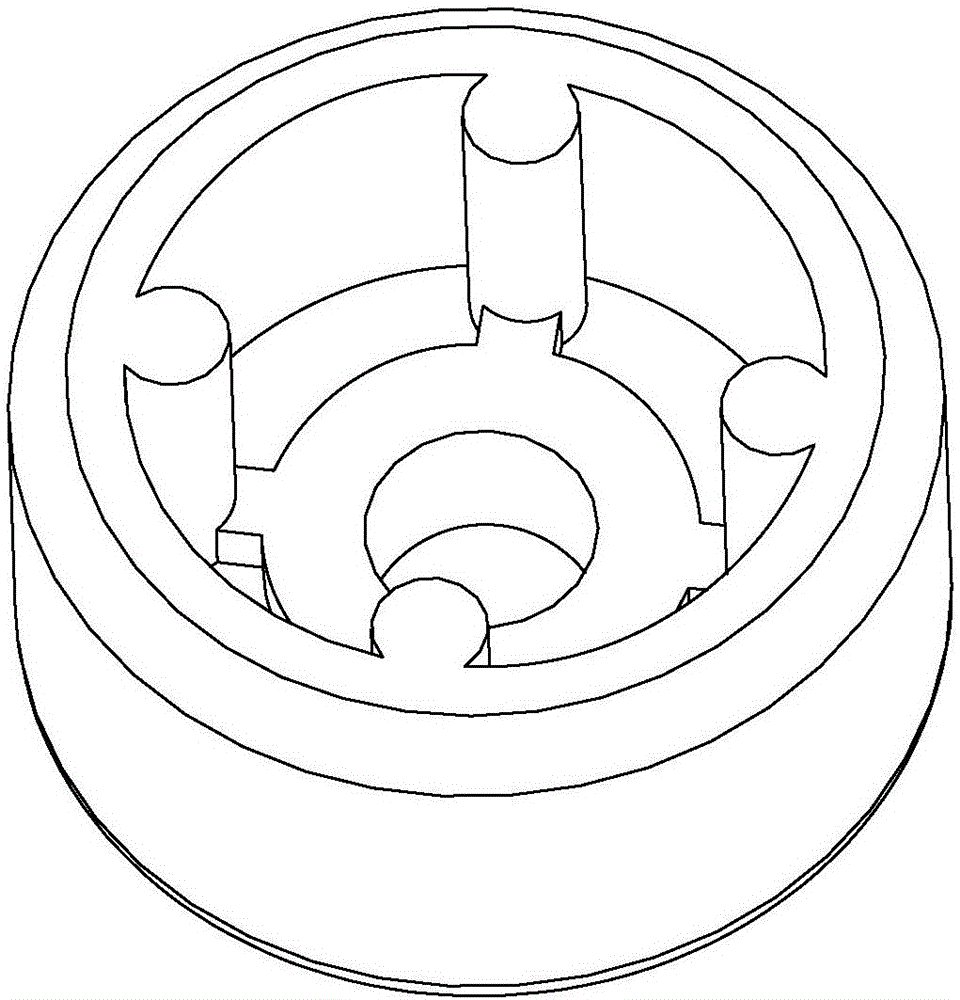

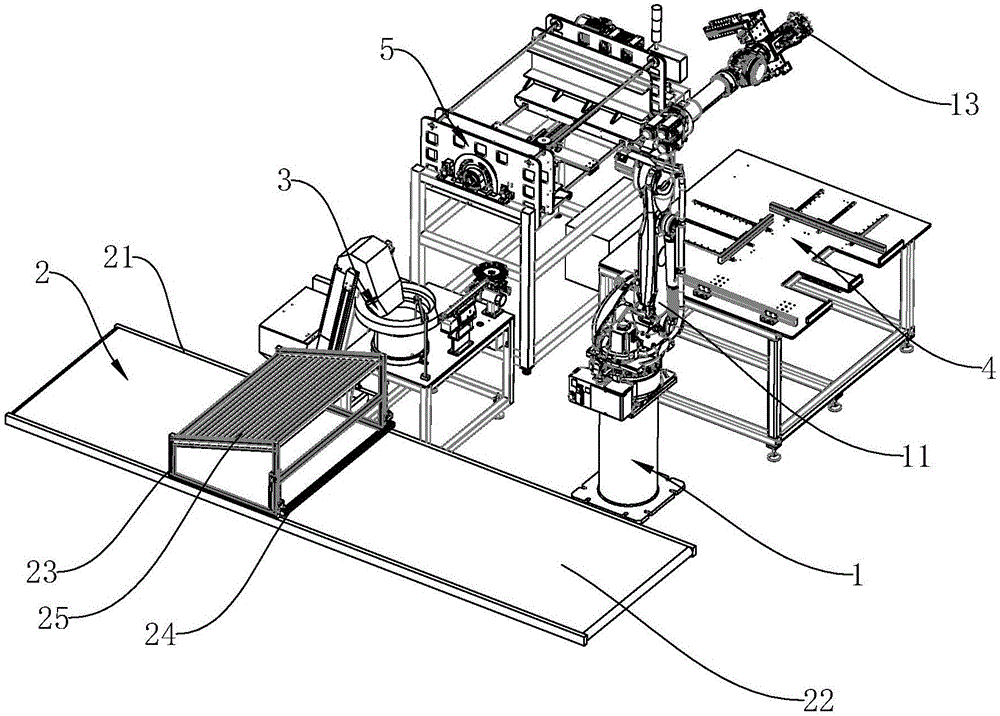

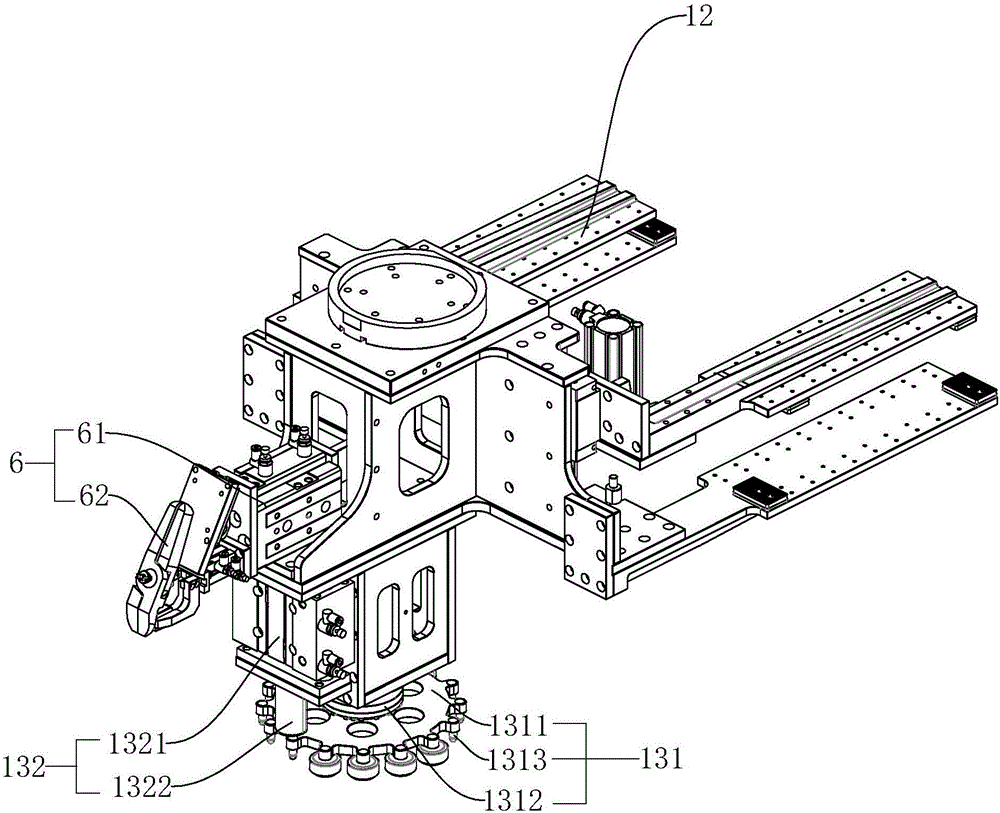

[0032] Embodiment 1: As shown in the figure, an automatic assembly line for plastic pallets includes a manipulator assembly 1. The manipulator assembly 1 consists of a manipulator 11 with six degrees of freedom and a gripper 12 and feet arranged on the manipulator 11. The installation mechanism 13 is composed of;

[0033] A conveying device 2, the conveying device 2 conveys the plastic tray injection-molded by the injection molding machine for gripping by the gripper 12; and conveys the plastic tray with feet installed on both sides transferred by the gripper 12;

[0034] A foot feeding device 3, the foot feeding device 3 provides automatically arranged feet for the foot installation mechanism 13 to obtain;

[0035] A pallet positioning device 4, after the pallet positioning device 4 clamps the plastic pallet provided by the jaws 12, the foot installation mechanism 13 provides the feet and makes the feet installed on the upward surface of the plastic pallet; and

[0036] A tr...

Embodiment 2

[0037] Embodiment 2: As shown in the figure, an automatic assembly line for plastic pallets includes a manipulator assembly 1. The manipulator assembly 1 consists of a manipulator 11 with six degrees of freedom and a gripper 12 and feet arranged on the manipulator 11. The installation mechanism 13 is composed of;

[0038] A conveying device 2, the conveying device 2 conveys the plastic tray injection-molded by the injection molding machine for gripping by the gripper 12; and conveys the plastic tray with feet installed on both sides transferred by the gripper 12;

[0039] A foot feeding device 3, the foot feeding device 3 provides automatically arranged feet for the foot installation mechanism 13 to obtain;

[0040] A pallet positioning device 4, after the pallet positioning device 4 clamps the plastic pallet provided by the jaws 12, the foot installation mechanism 13 provides the feet and makes the feet installed on the upward surface of the plastic pallet; and

[0041] A tr...

Embodiment 3

[0051] Embodiment 3: As shown in the figure, an automatic assembly line for plastic pallets includes a manipulator assembly 1. The manipulator assembly 1 consists of a manipulator 11 with six degrees of freedom, a gripper 12 and a pad set on the manipulator 11. The installation mechanism 13 is composed of;

[0052] A conveying device 2, the conveying device 2 conveys the plastic tray injection-molded by the injection molding machine for gripping by the gripper 12; and conveys the plastic tray with feet installed on both sides transferred by the gripper 12;

[0053] A foot feeding device 3, the foot feeding device 3 provides automatically arranged feet for the foot installation mechanism 13 to obtain;

[0054] A pallet positioning device 4, after the pallet positioning device 4 clamps the plastic pallet provided by the jaws 12, the foot installation mechanism 13 provides the feet and makes the feet installed on the upward surface of the plastic pallet; and

[0055] A tray turnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com