Production line object part motion detection and tracking method based on videos

A motion detection, production line technology, applied in image data processing, instrumentation, computing, etc., can solve problems such as missed detection, and achieve the effect of reducing missed detection rate, increasing robustness, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

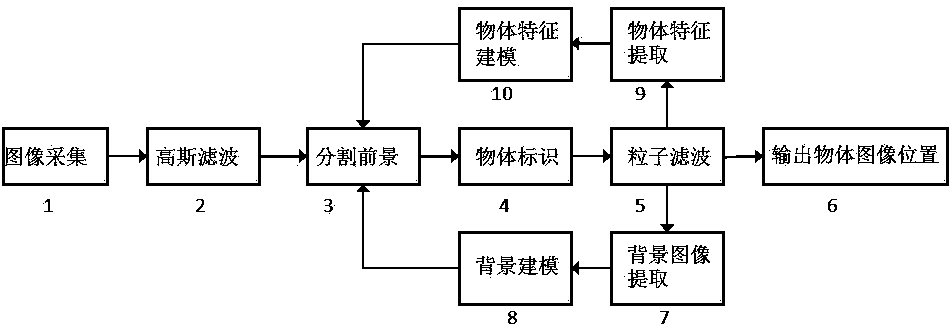

[0019] As shown in the figure, it is a video-based motion detection and tracking method for production line item parts, which is implemented by the following software modules: image acquisition, Gaussian filtering, foreground segmentation, item identification, particle filter, item feature extraction and model Update, background image extraction and background model update, output object image position.

[0020] When performing detection and tracking, follow the steps below:

[0021] 1) Image acquisition: a single digital camera is used to acquire the images of the production line running without load and the actual running production line images; the camera used for image acquisition is connected to the industrial computer through a 1394 digital acquisition card, and the camera is installed above the production line. The downward angle of 30°~90° in the direction;

[0022] 2) Background generation: Gaussian filtering is performed on the acquired no-load running image for a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com