Assembly device and assembly method for rotor core

A technology of rotor iron core and assembly device, which is applied in the direction of manufacturing stator/rotor body, etc., can solve the problems of low positioning accuracy of rotor iron core, prone to substandard products, low degree of automation, etc., and achieves stable and reliable moving process and assembly efficiency. High, highly automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

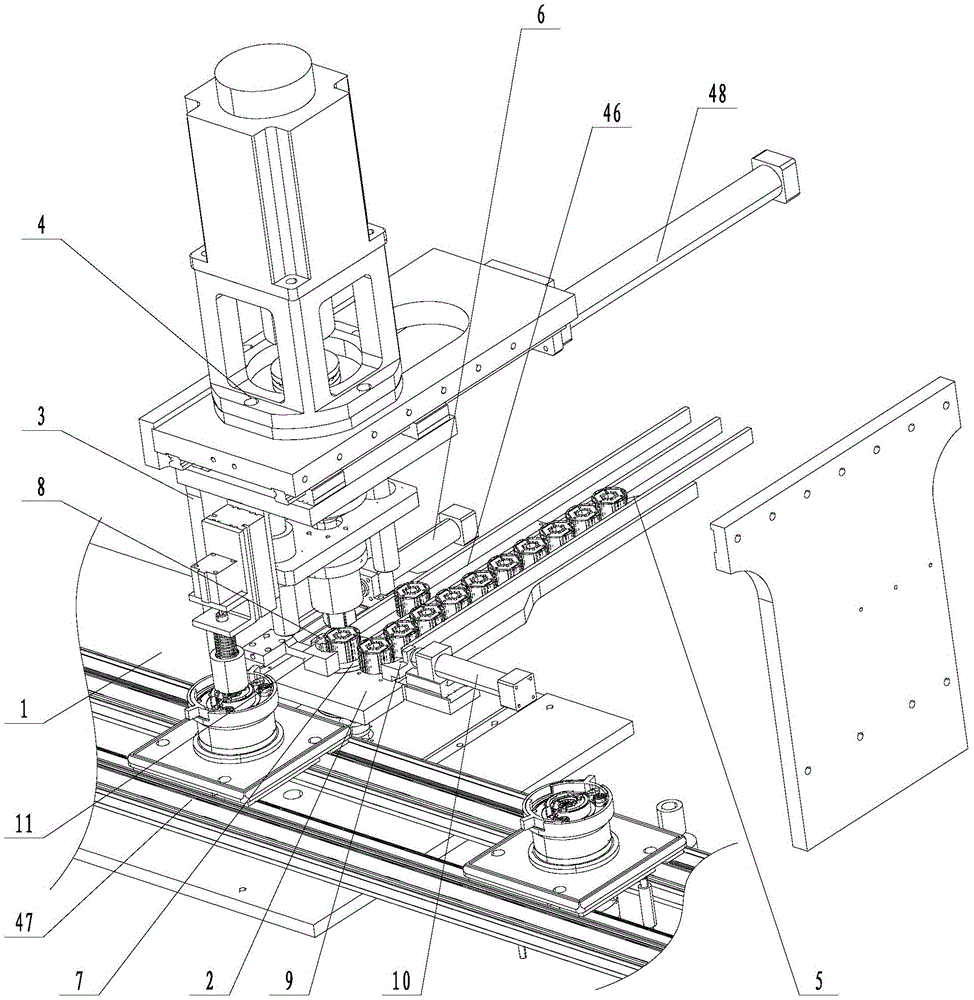

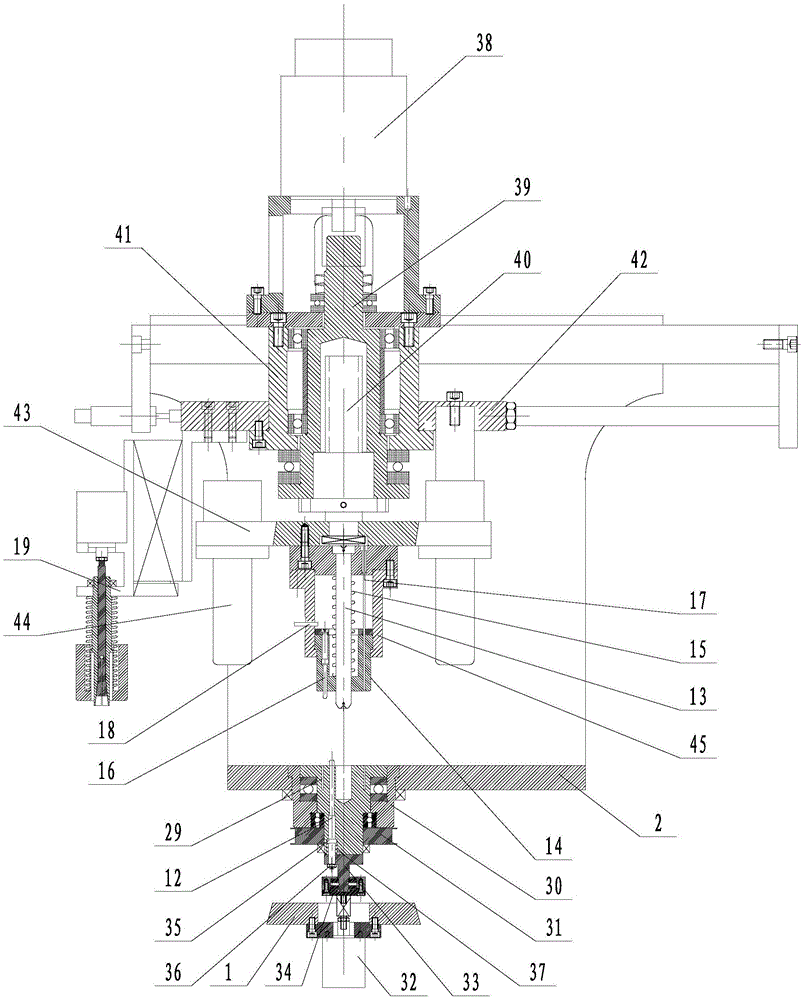

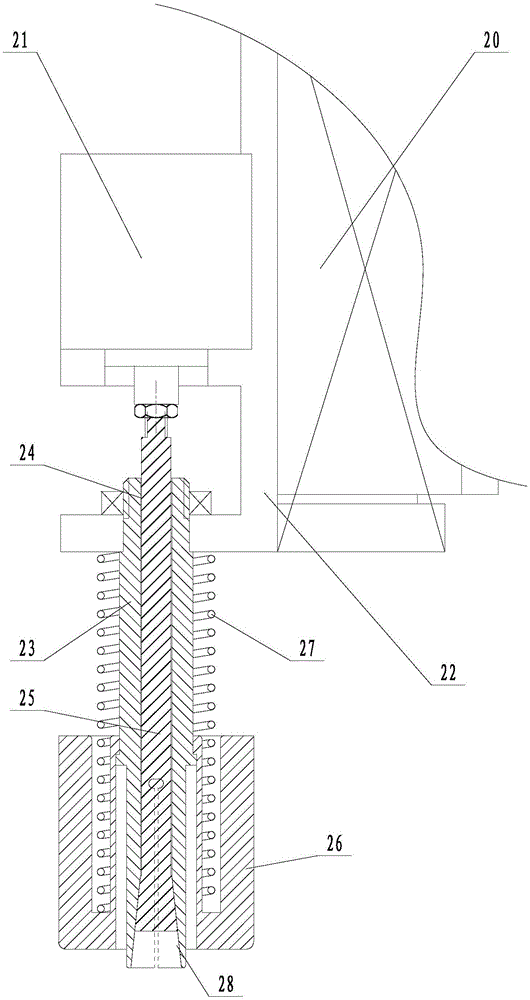

[0023] Embodiment: A rotor core assembly device (see attached Figures 1 to 3 ), including a mounting base 1 installed on the motor rotor assembly line 47, a support plate 2 and a bracket 3 connected to the mounting base, a compression shaping mechanism 4 that can be translated and installed on the bracket, and a feeding channel 5 is provided on the support plate 1. Push out the piston cylinder 6, a liftable turntable 7 is installed on the support plate near one end of the feeding passage, and a fixed shaping head 8 and a moving shaping head 9 are respectively arranged on both sides of the feeding passage on the supporting plate, and the fixed shaping head and the moving shaping head The opposite inner surface of the shaping head is in a concave arc-shaped structure, the fixed shaping head is firmly connected to the support plate, the moving shaping head is connected to the telescopic rod of the feeding piston cylinder 10, and the front end of the telescopic rod of the pushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com