Automatic tightening assembly equipment

An assembly equipment and automatic technology, applied in metal processing equipment, devices for coating liquid on the surface, metal processing, etc., can solve the problems of difficult control and detection of glue coating quality, difficulty of anaerobic thread glue, etc., to improve production Efficiency and product quality, good flexibility, and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

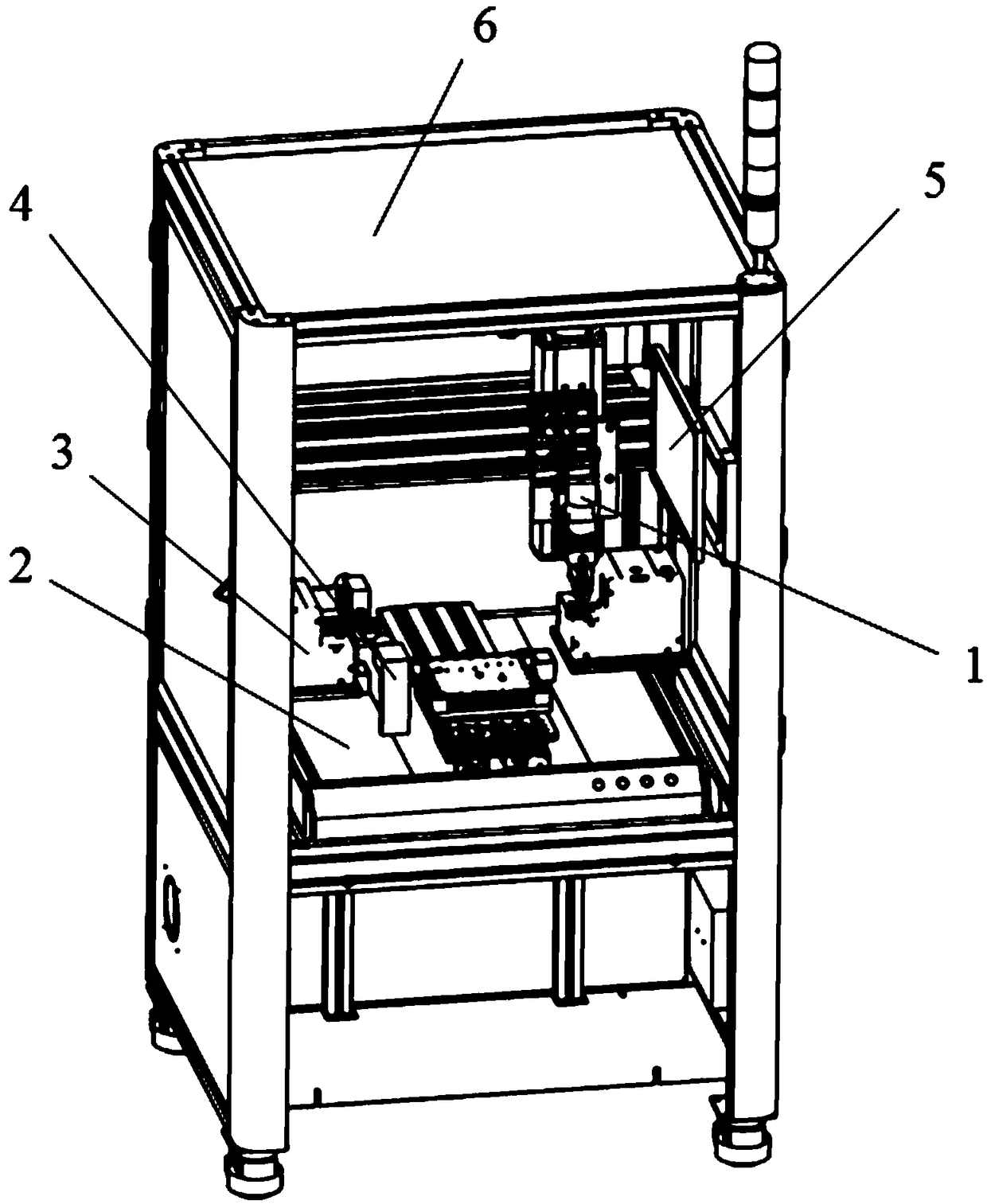

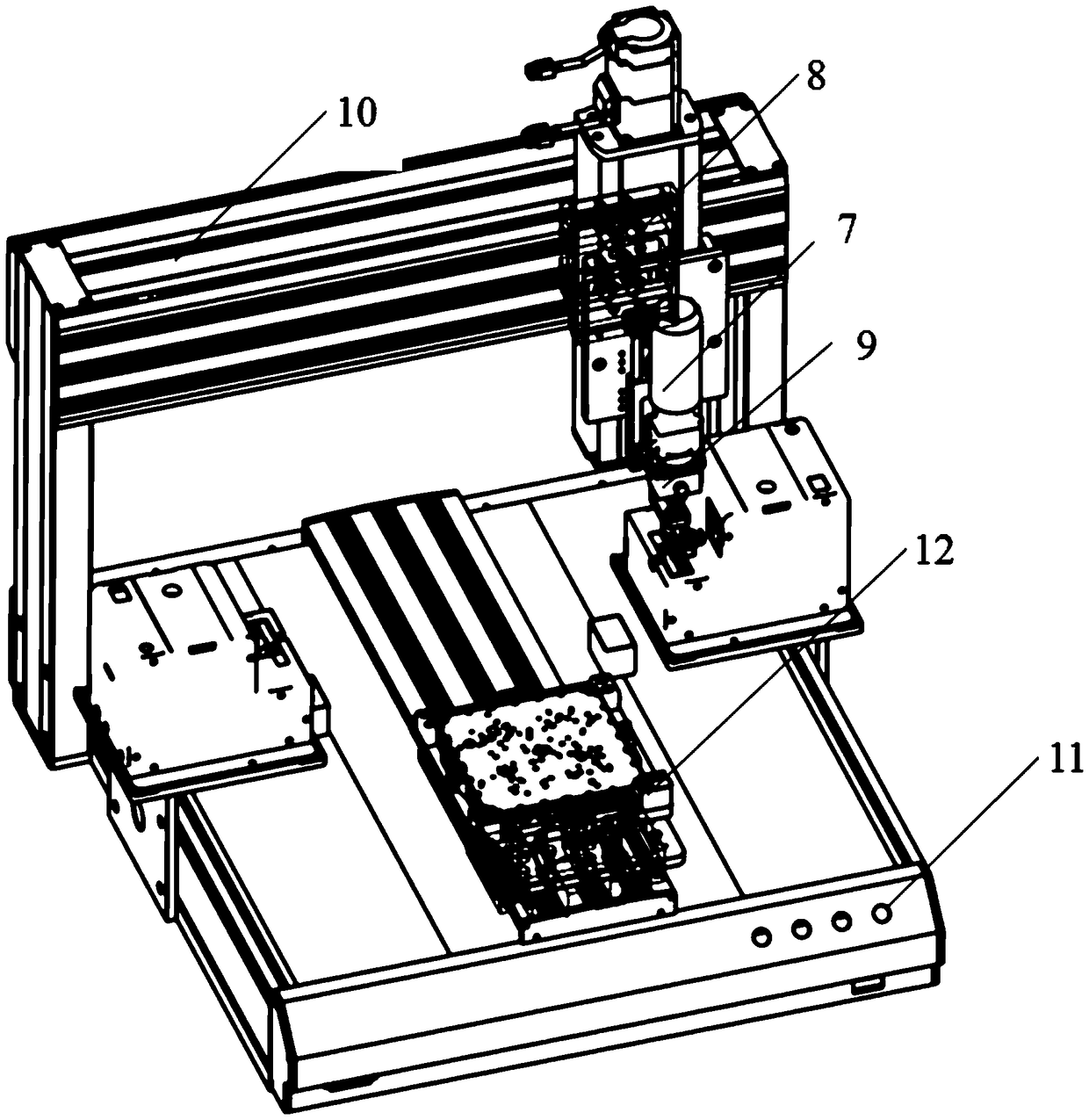

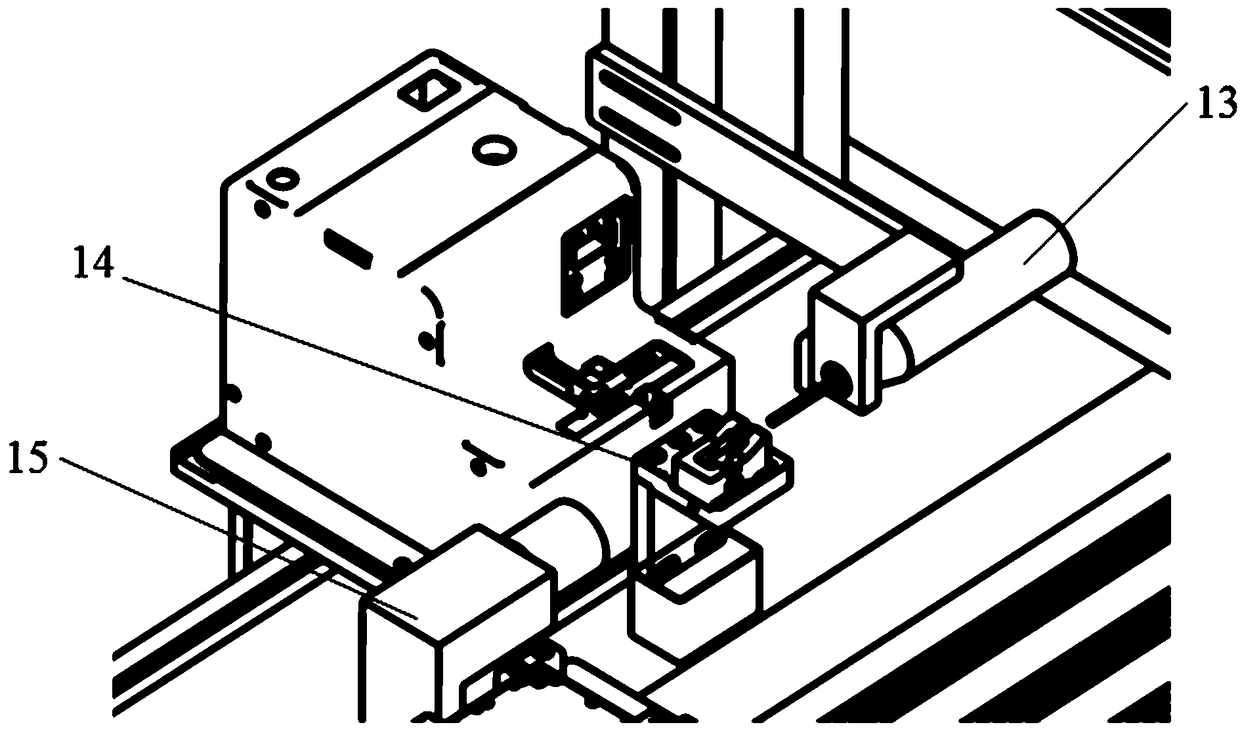

[0034] based on the following Figure 1 ~ Figure 3 , specifically explain the preferred embodiment of the present invention.

[0035] Such as figure 1 As shown, the present invention provides an automatic tightening assembly equipment, comprising:

[0036] equipment rack 6;

[0037] A high-precision motion execution module 2, which is installed on the equipment rack 6, is used to realize the fast servo motion and precise positioning of the screw tightening module 1;

[0038] Screw tightening module 1, which is installed on the high-precision motion execution module 2, is used to realize the suction and automatic tightening of screws;

[0039] Screw feeding module 3, which is installed on the equipment rack 6, is used to realize automatic arrangement of scattered screws and separate feeding one by one;

[0040] Glue control and detection module 4, which is installed on the equipment rack 6, is used to provide anaerobic thread glue and realize liquid level control and automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com