Cover and spoon dispensing assembly automatic equipment and production system

A production system and glue dispensing technology, applied in packaging, metal processing, etc., can solve problems such as high scrap rate, increased labor cost and product cost, and low efficiency of operators in glue application, so as to save labor and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

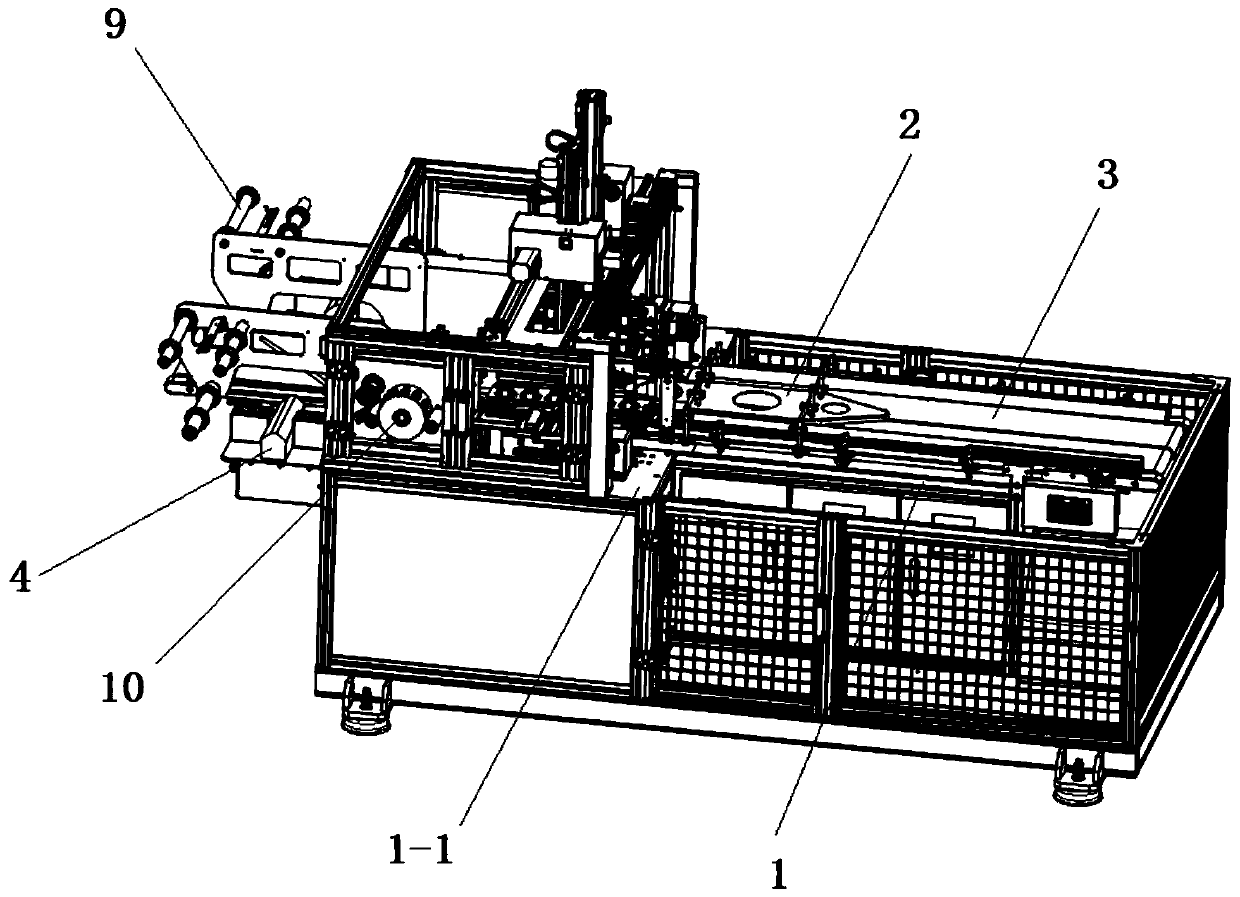

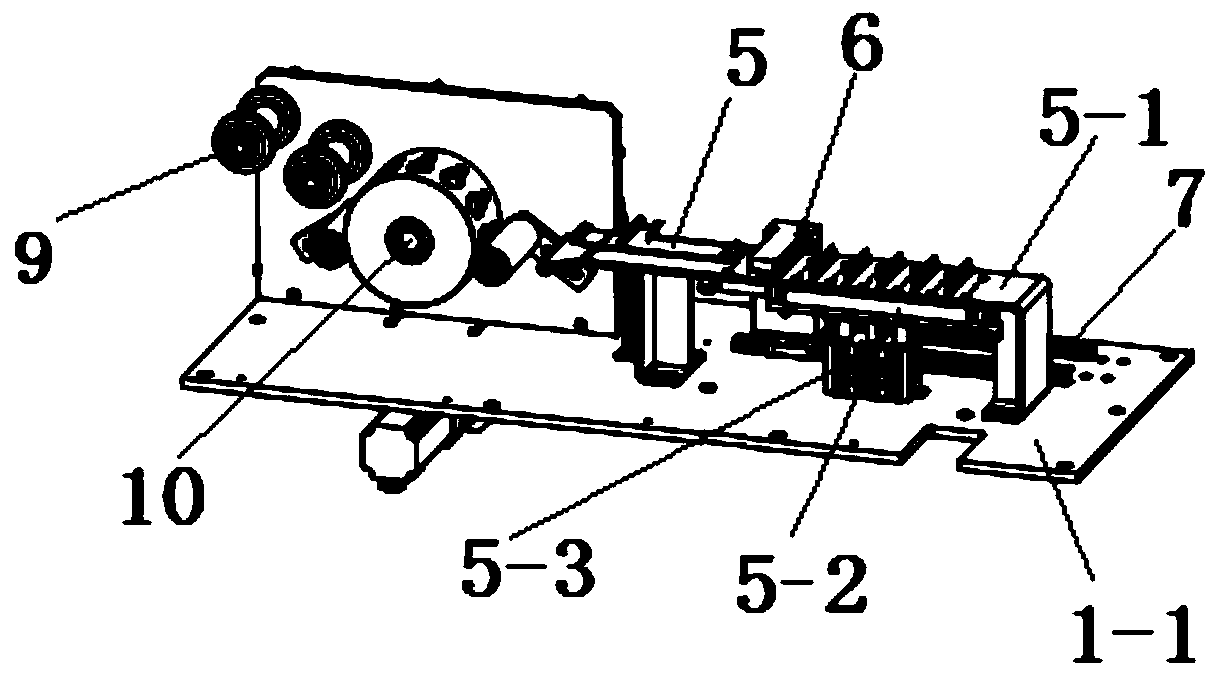

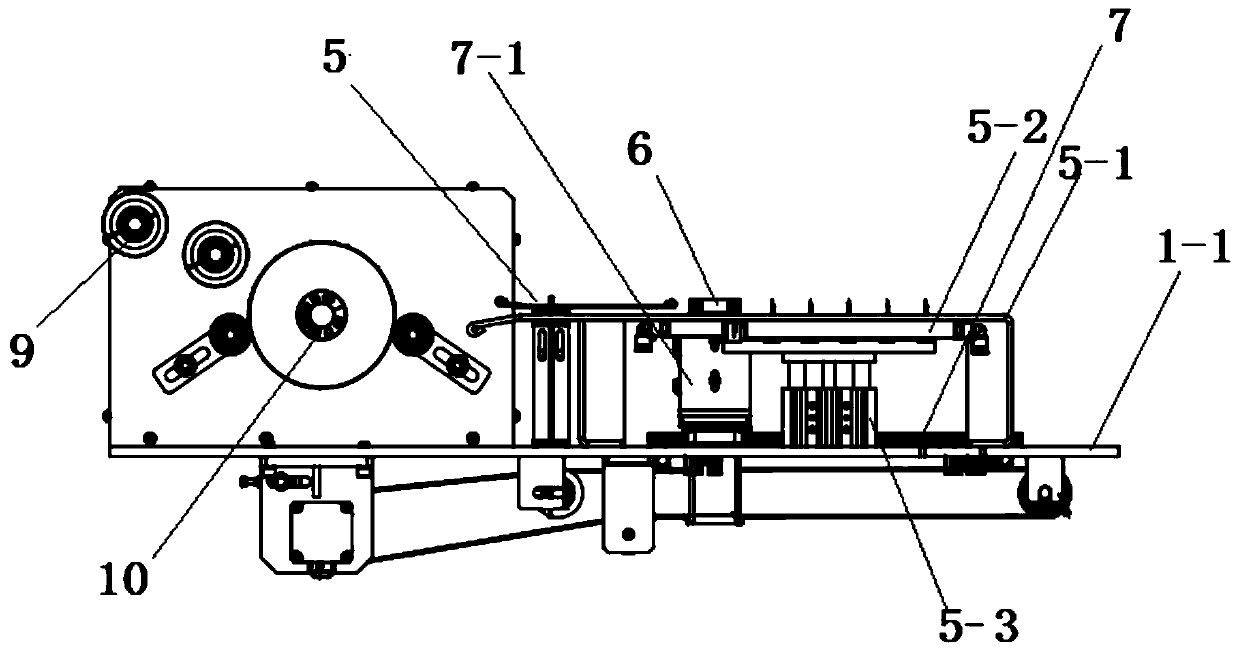

[0028] As shown in the figure, an automatic production system for cap and spoon dispensing assembly provided by the present invention includes a first operating platform, and a conveyor belt 3 is provided on the first operating platform 1, and a conveyor belt 3 is provided on the conveyor belt 3. Raised diverter plate 2, one end of the diverter plate 2 is a triangle, one side of the triangle is connected to a rectangle, which is in the shape of a three-dimensional arrow, and the triangular design diverts the upper cover to the diversion channels on both sides and transports them to the double station on the production line; the dispensing device is provided above the diversion channel between the diverter plate 2 and the conveyor belt 3, and is used to glue the upper covers that line up into the diversion channel in sequence; Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com