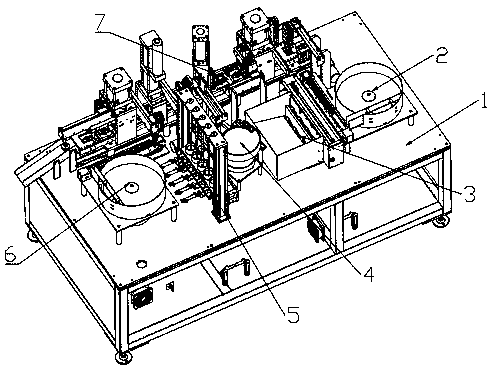

Bearing part assembling automatic equipment

A technology of automation equipment and bearing parts, which is applied in the field of bearing assembly and processing, can solve the problems of large working space, low safety performance, and low work efficiency, and achieve the effects of improving work efficiency, reducing workload, and reducing work space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0028] The second embodiment is different from the above in that a heat dissipation device is arranged inside the workbench 1, and the heat dissipation device is used to dissipate heat from the mechanisms on the workbench 1.

Embodiment 3

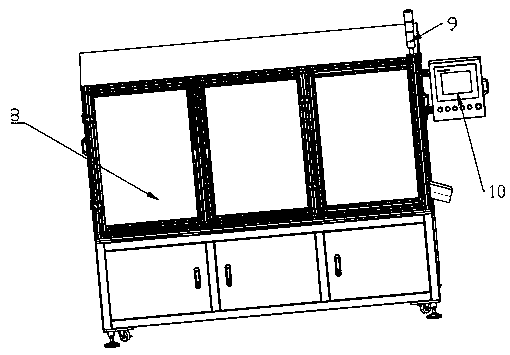

[0029] The third embodiment is different from the above in that an alarm light 9 is installed at the upper end of the protective cover 8 and a controller 10 is installed on the side of the protective cover 8 above the discharge port.

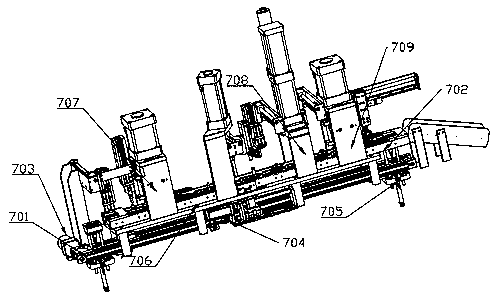

[0030] The working principle of the present invention: firstly, the worker opens the machine through the controller 10, and then opens the side panels through the handle on the protective cover 8, and then puts different materials into the corresponding mechanism in sequence. First, the first oscillation Mechanism 2 works. The inner bearing is transported to the first direct vibration device through the first oscillating disc. The first direct vibration device transports the bearing to the bottom of the first grabbing device at the end, and the first grabbing device grabs the bearing below. Take it into the mold on the second moving rail 702. When the mold moves to the next station, the axis mechanism 3 starts to work, and the lifting cylinder trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com