Pneumatic automatic device for assembling binder clips

A technology of automatic device and long tail clamp, which is applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., and can solve the problems of high manpower occupation, low assembly efficiency, and high labor cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

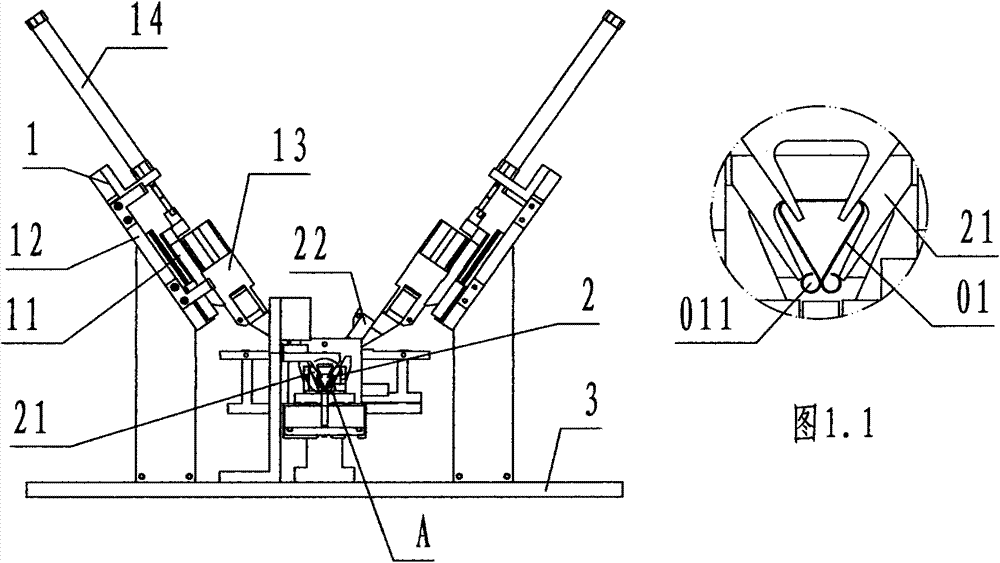

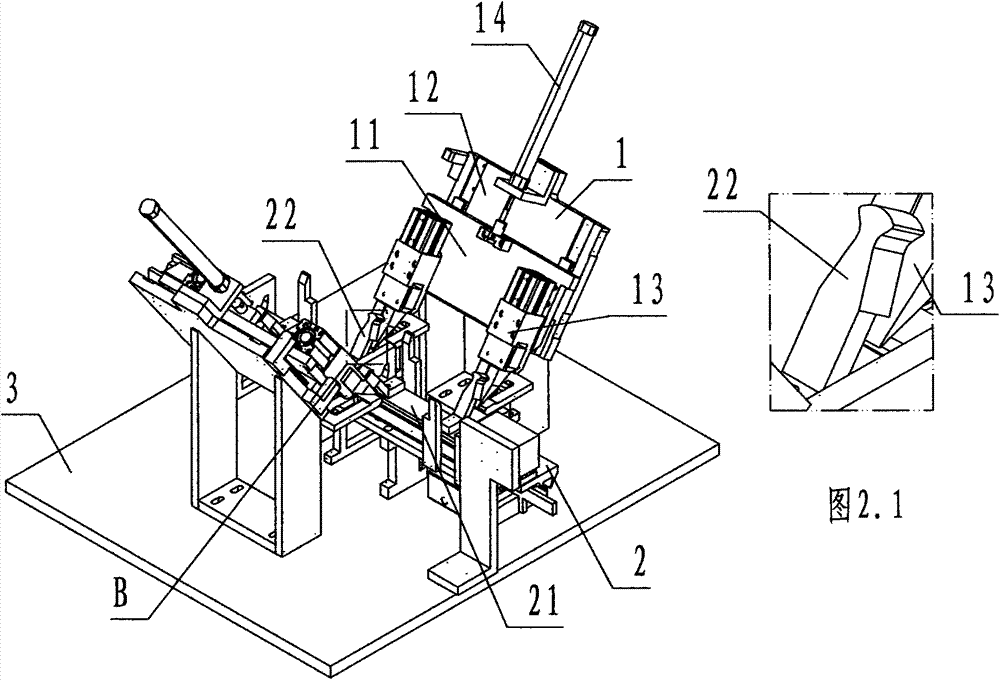

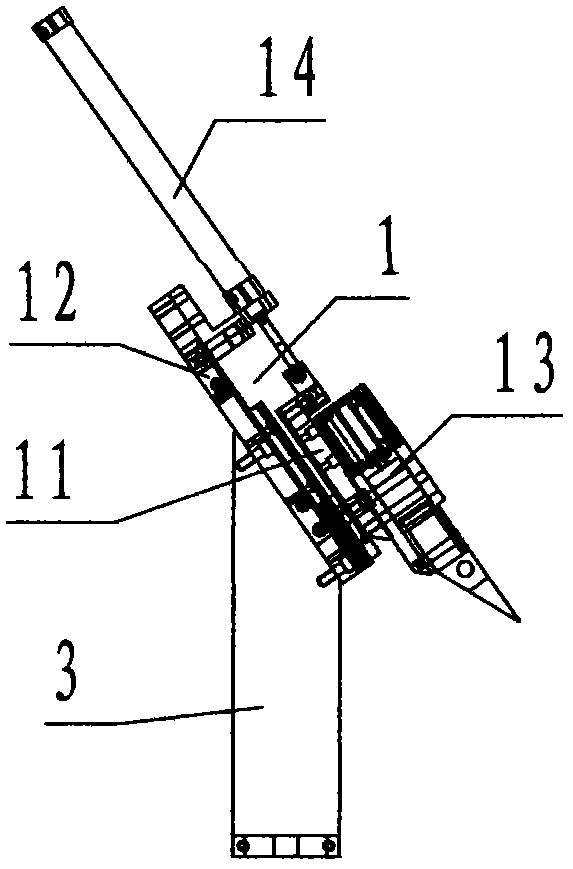

[0027] Refer to Figure 1~Figure 8 , The pneumatic automatic device for assembling long tail clamps of the present invention includes a manipulator 1, a conveying path 2, and a base 3. The manipulator 1 is composed of a sliding plate 11, a carrier plate 12, a pneumatic clamp 13, and a sliding plate cylinder 14. The carrier board 12 is a rectangular block-shaped steel plate, and the front and rear sides of the carrier board 12 are provided with up and down, mutually parallel, convex T-shaped rails called slide rails; the slide plate 11 is a rectangular block shape The front and rear sides of the sliding plate 11 are provided with T-shaped sliding grooves corresponding to the sliding rails of the carrier plate 12; the pneumatic clamp 13 is a pneumatic opening and closing clamp composed of an air cylinder and a clamp Actuator; the clamp of the pneumatic clamp 13 faces right, and the two pneumatic clamps 13 are respectively fixed on the front and rear parts of the sliding plate 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com