Swivel hook type hook injection mould capable of automatically assembling lifting hook

An automatic assembly and hook-type technology, which is applied in the field of injection molds, can solve the problems of low efficiency, high work intensity, and high labor cost, and achieve the effects of reducing costs, improving efficiency, and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

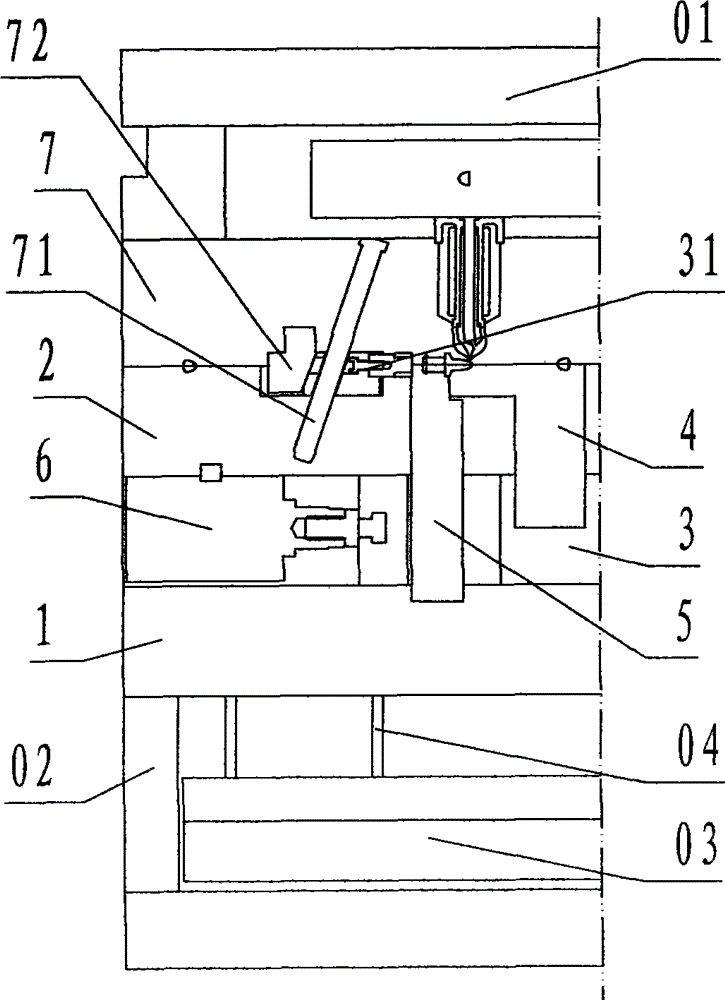

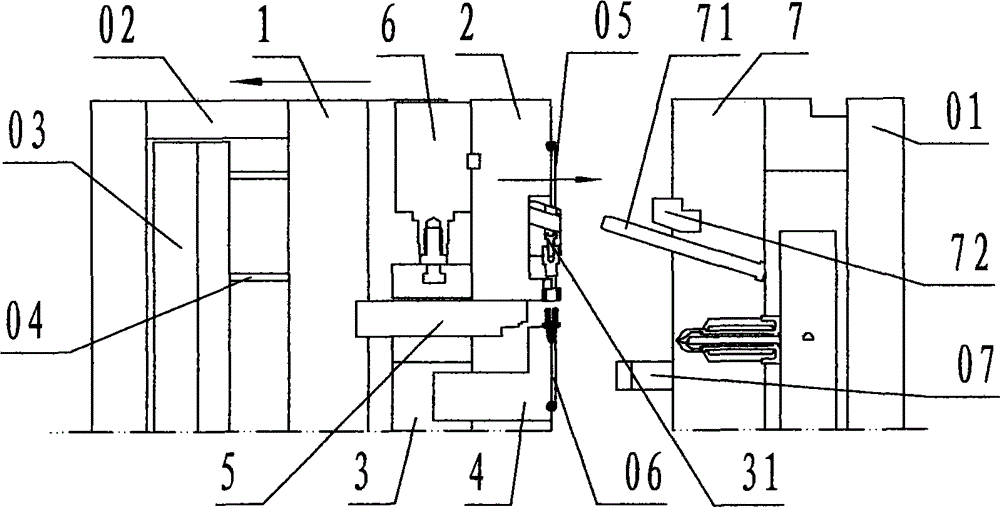

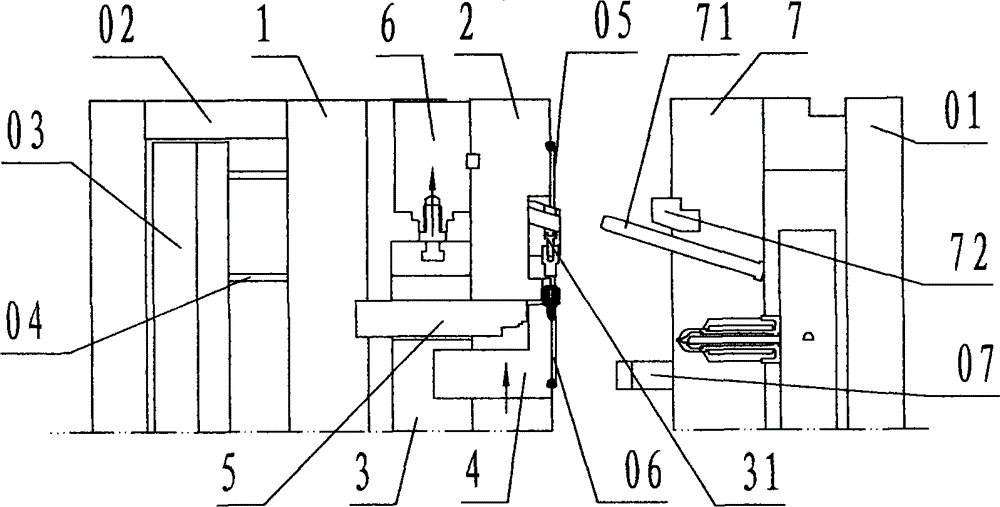

[0027] refer to Figure 1 ~ Figure 4 , a rotary hook type hanger injection mold for automatically assembling hooks of the present invention, comprising a moving mold carrier plate 1, a longitudinal slider 2, a horizontal slider 3, a neck hole core puller 31, a rotary hook core block 4, and a hook neck core Block 5, oil cylinder 6, fixed mold support plate 7, inclined guide column 71, wedge block 72, wherein: the described movable mold support plate 1 is a rectangular plate-shaped steel bearing member fixedly arranged on the movable mold 02 part of the mold, The top of the movable mold carrier plate 1 is provided with a groove for carrying the longitudinal slider 2 for longitudinal sliding, which is called a longitudinal chute;

[0028] The longitudinal slider 2 is a rectangular block-shaped steel member. The upper left part of the longitudinal slider 2 is provided with a lower half cavity for forming the hanger part 05, which is called the lower cavity of the hanger. The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com