System for determining SO3 in flue gas

A measurement system and flue gas technology, applied in the field of SO3 measurement system in flue gas, can solve the problems of reduced accuracy and precision, difficulty in SO3 measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, the present invention will be described in detail with reference to specific embodiments of the present invention.

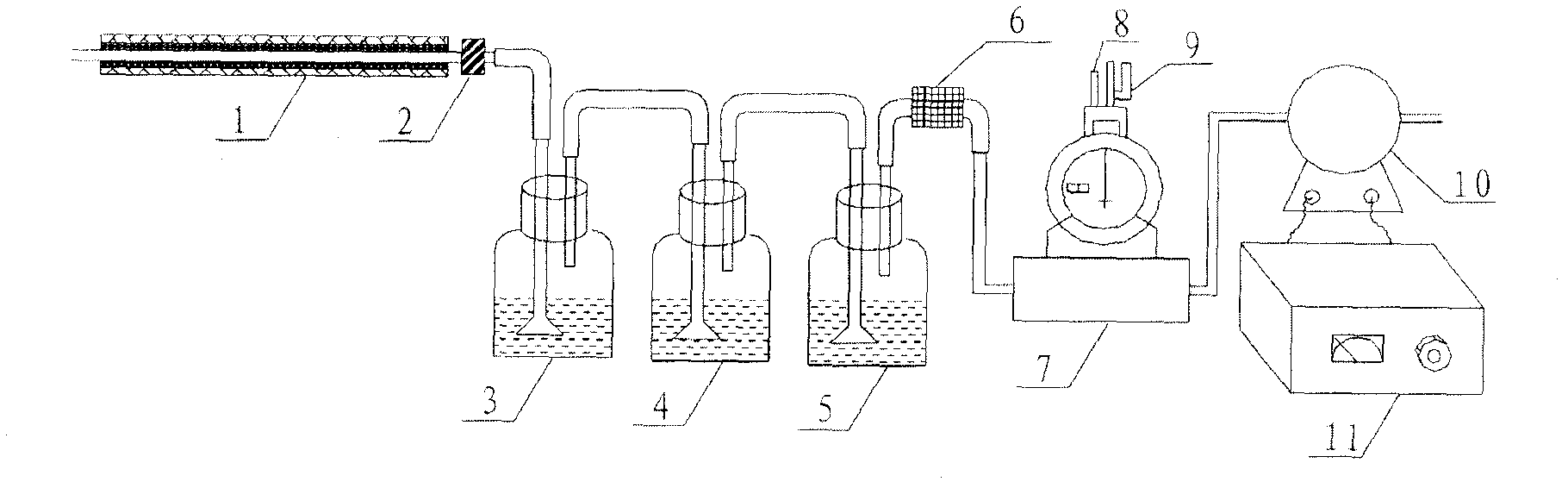

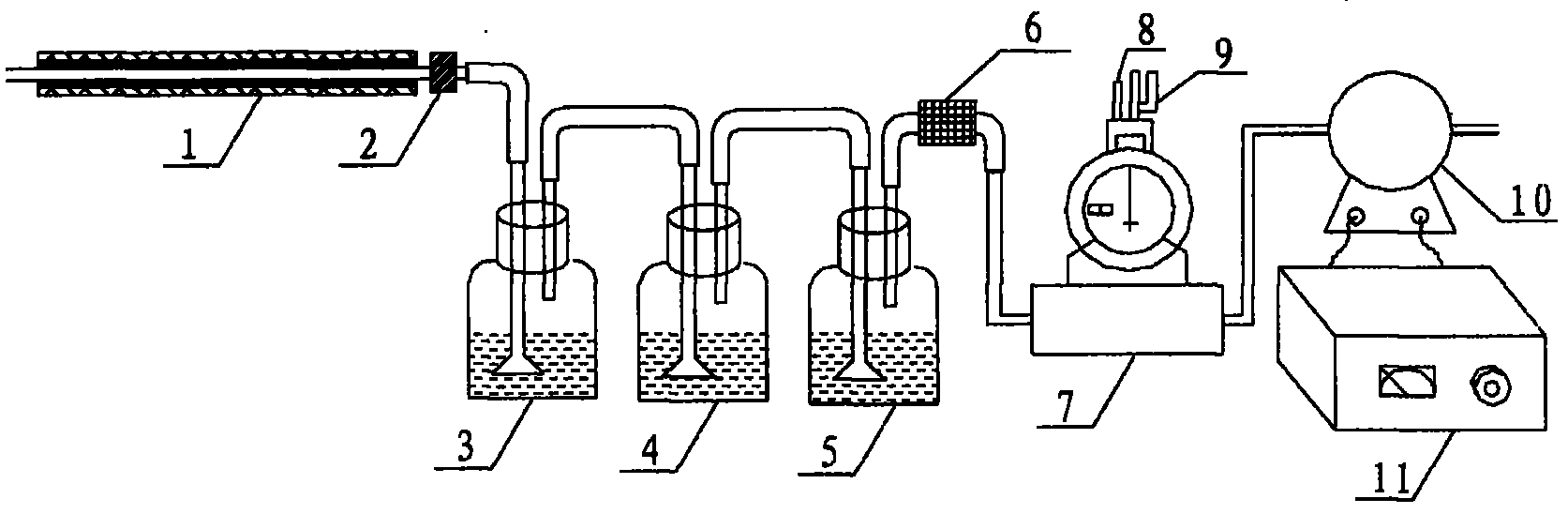

[0019] SO in flue gas according to the present invention 3 The measurement system includes sampler, absorber, gas flow meter and vacuum pump.

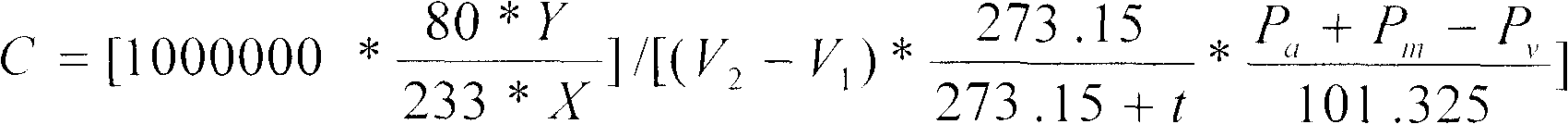

[0020] The sampler has a heating function to heat the sampled sintering flue gas to prevent moisture in the sintering flue gas from condensing and absorbing SO in the sintering flue gas 3 , so as to ensure that the SO in the sintering flue gas 3 Assay accuracy and reliability. The absorber is filled with isopropanol aqueous solution with a concentration of 70%-85% and connected to the outlet of the sampler. in isopropanol aqueous solution. To prevent SO 3 The gas is not fully absorbed in the isopropanol aqueous solution, and two or more absorbers can be installed. A gas flow meter is connected to the outlet of the absorber to measure the volume of flue gas. The vacuum pump is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com