Fast pyrolytic test device and application

A testing device and pyrolysis technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of temperature deviation, not, etc., and achieve the effects of simple operation, low equipment cost, and high cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

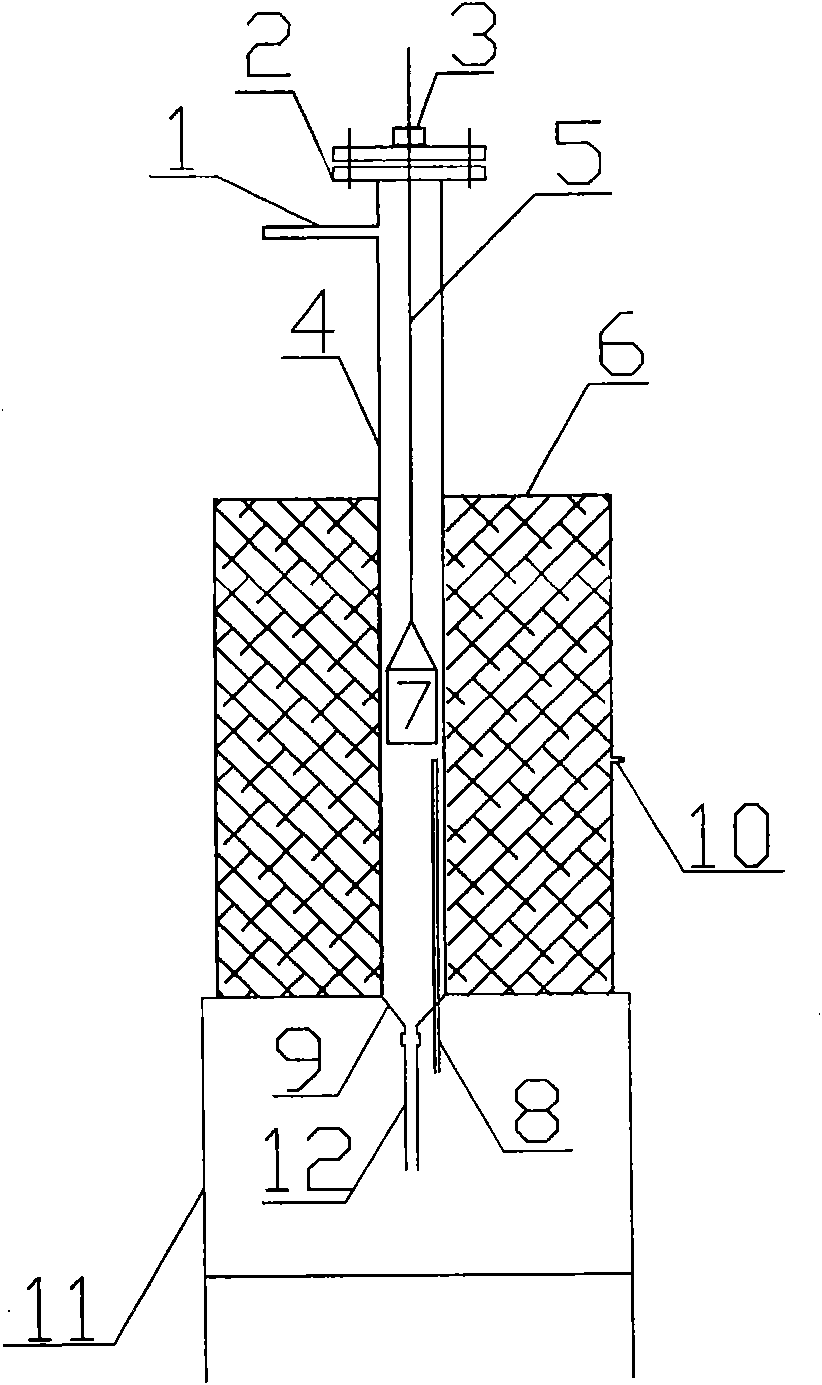

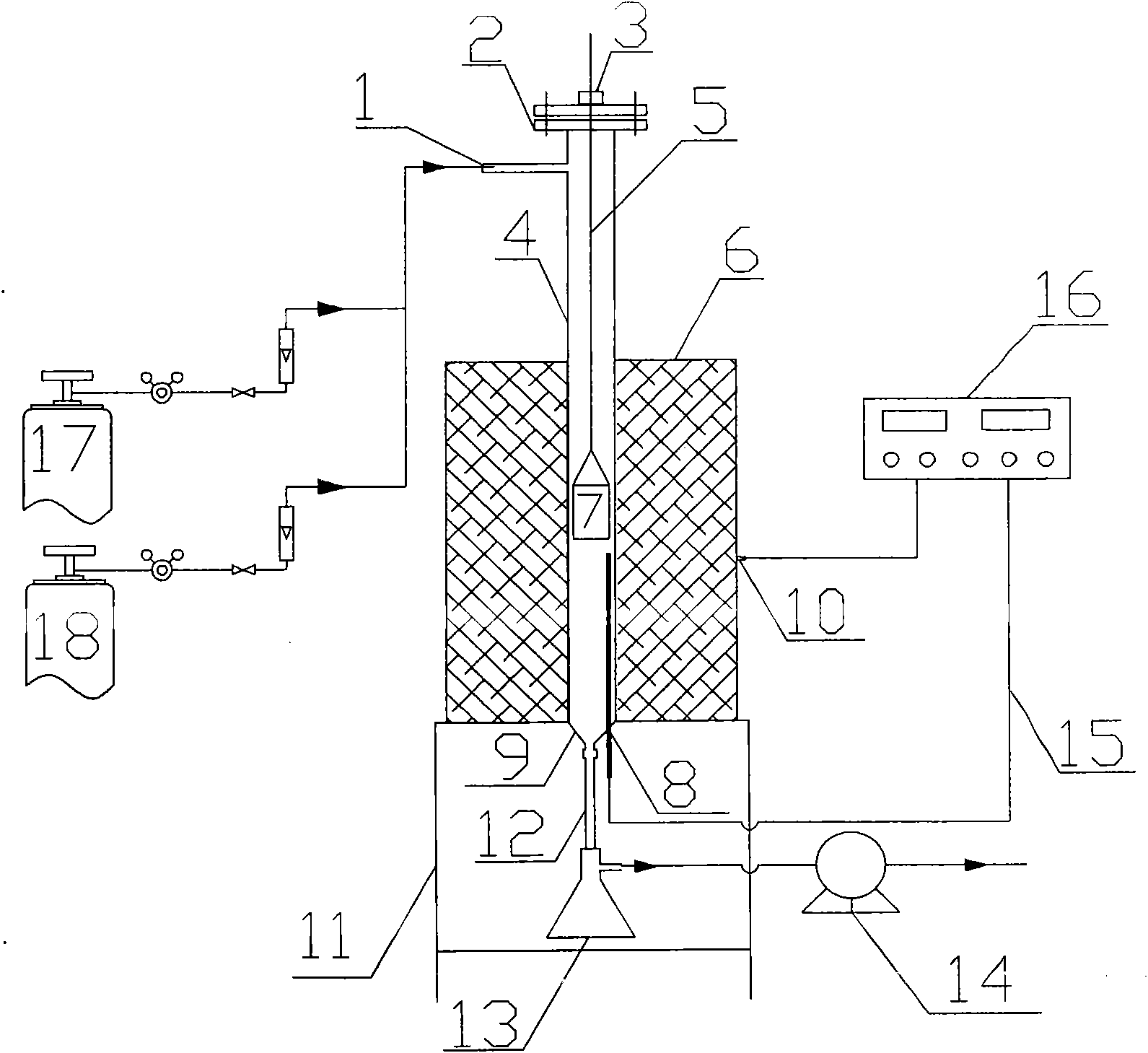

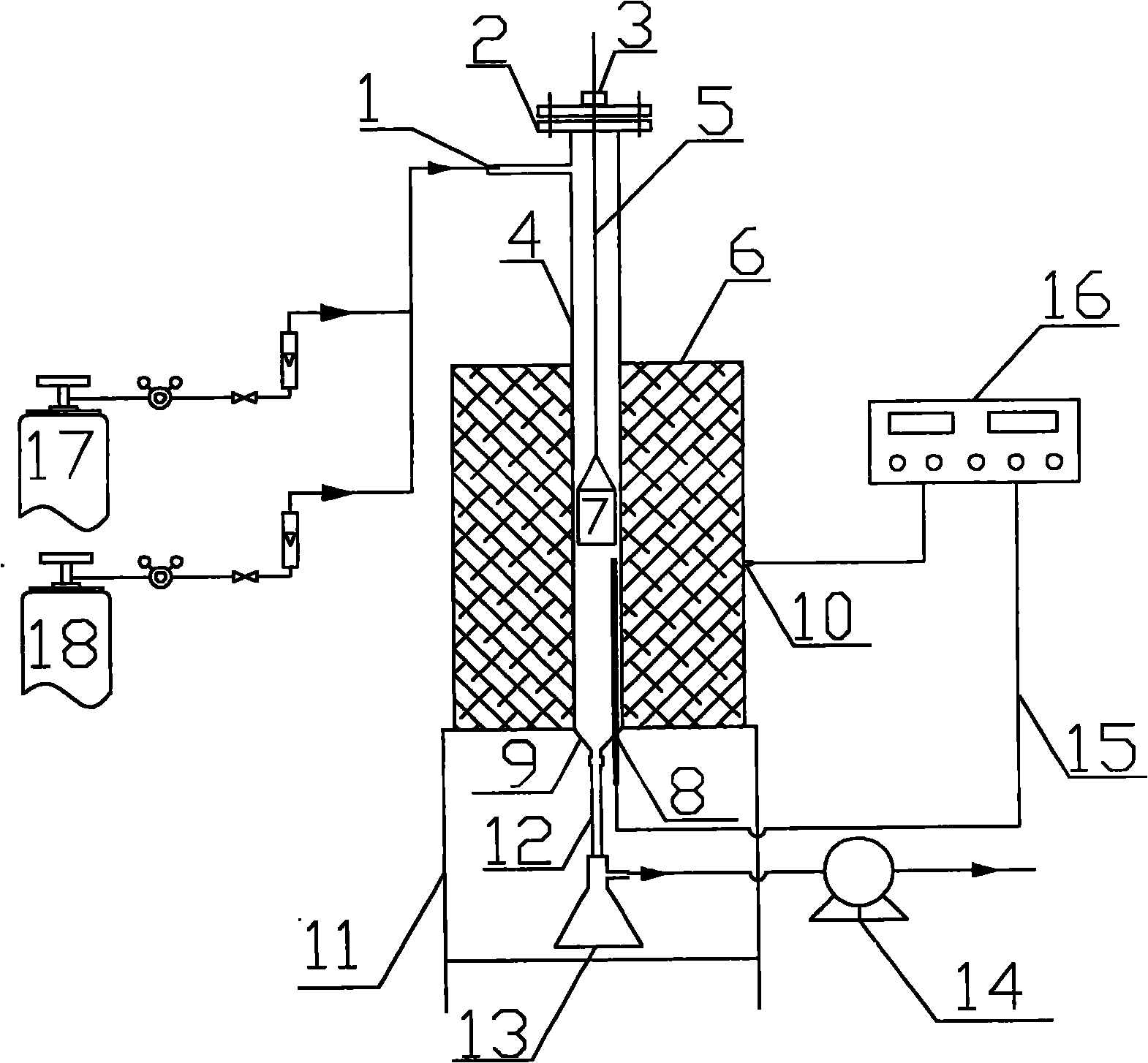

[0030] Fast pyrolysis of lignite:

[0031] The upper part of the reaction tube 4 has an air inlet 1, the top of the reaction tube 4 has an adjustable seal 3, and there is a stainless steel rod 5 inside the reaction tube 4, the top of the stainless steel rod 5 is connected to the adjustable seal 3, and the lower end of the stainless steel rod 5 is connected to the sample. The hanging basket 7 is connected, the middle and lower part of the reaction tube 4 is located in the tubular electric heating furnace 6, the bottom of the reaction tube 4 has a temperature measuring port 8 and a conical oil and gas outlet 9, and the conical gas outlet 9 is connected to the oil and gas outlet 12, The tubular electric heating furnace 6 is located on the object rack 11 .

[0032] (1), the PTC-2 type temperature controller 16 produced by the Shanxi Coal Chemical Institute of the Chinese Academy of Sciences is connected with the thermocouple in the temperature measuring port 8 at the bottom of the...

Embodiment 2

[0042] Fast pyrolysis of corncob:

[0043] In this example, the raw material is corn cob with a particle size of less than 3mm, the amount of raw material is 2g, the temperature controller is AI-708 produced by Xiamen Yudian, the pyrolysis temperature is 900°C, the reaction atmosphere is methane, and the others are the same as in Example 1. . The pyrolysis data are shown in Table 1.

Embodiment 3

[0045] Fast pyrolysis of bagasse:

[0046] In this example, the raw material is bagasse with a particle size of less than 3 mm, the amount of raw material is 2 g, the temperature controller is SGM2843K produced by Sigma, the pyrolysis temperature is 800 ° C, and the reaction atmosphere is CO 2 , other with embodiment 1. The pyrolysis data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com