LabVIEW and PXI based automobile digital instrument testing system

A digital instrument and test system technology, which is applied in the field of automotive digital instrument test system, can solve problems such as incapable of professional testing, and achieve the effect of avoiding data loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

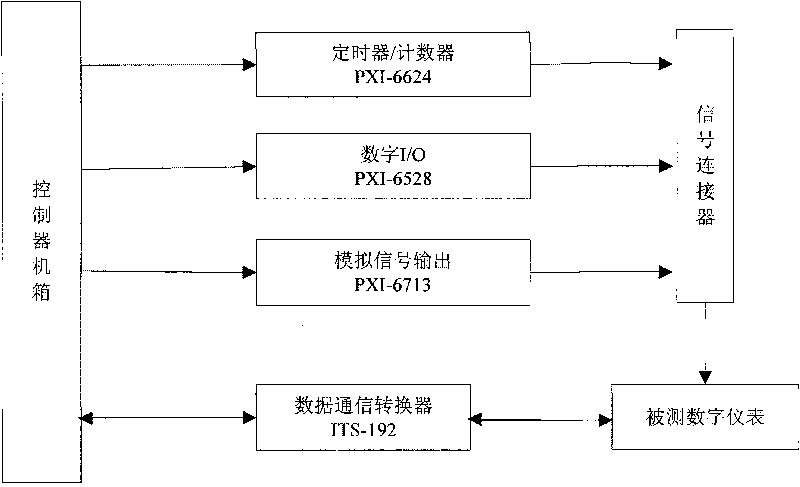

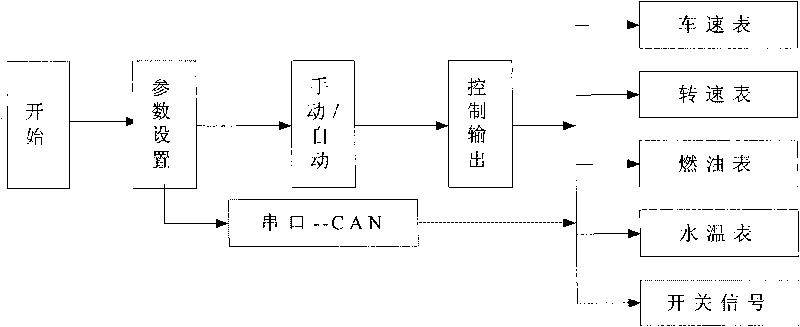

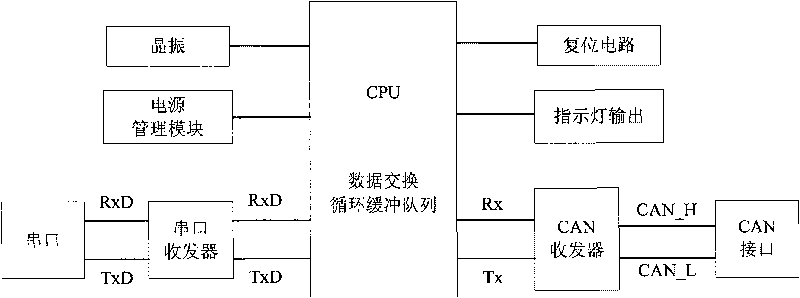

[0037]The automobile digital instrument test system of the present invention is a kind of automobile digital instrument test system based on LabVIEW and PXI, and its development requirement is aimed at different car models, can simulate and produce various acquisition signal information required by the instrument, and can communicate with the received instrument through the CAN interface Measuring instrument to communicate.

[0038] The automobile digital instrument test system based on LabVIEW and PXI of the present invention includes the following main functions.

[0039] 1. Simulate the pulse signal generation of the speedometer;

[0040] 2. The pulse signal simulation of the engine tachometer is generated;

[0041] 3. Simulation of vehicle fuel gauge signal generation;

[0042] 4. Simulation of vehicle water temperature gauge s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com