Method for extracting fault characteristic frequencies of train rolling bearings with variable rotational speeds

A technology of fault characteristic frequency and rolling bearings, applied in the direction of mechanical bearing testing, etc., can solve problems such as poor results, and achieve the effect of strong use flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

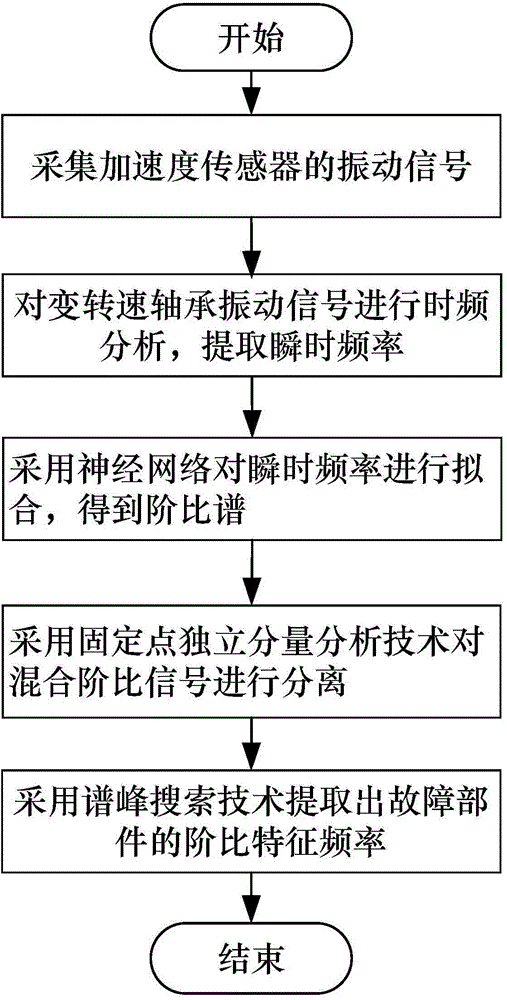

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with accompanying drawing:

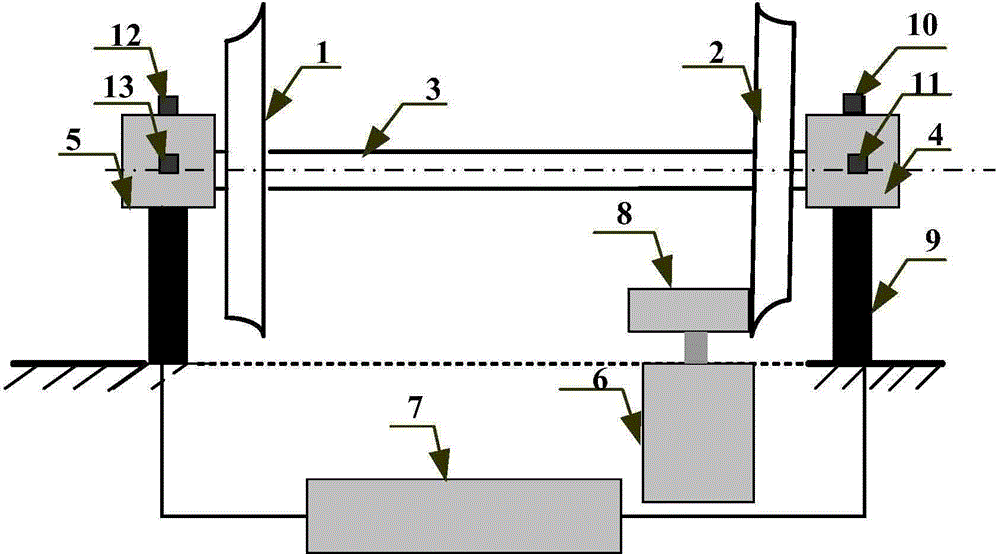

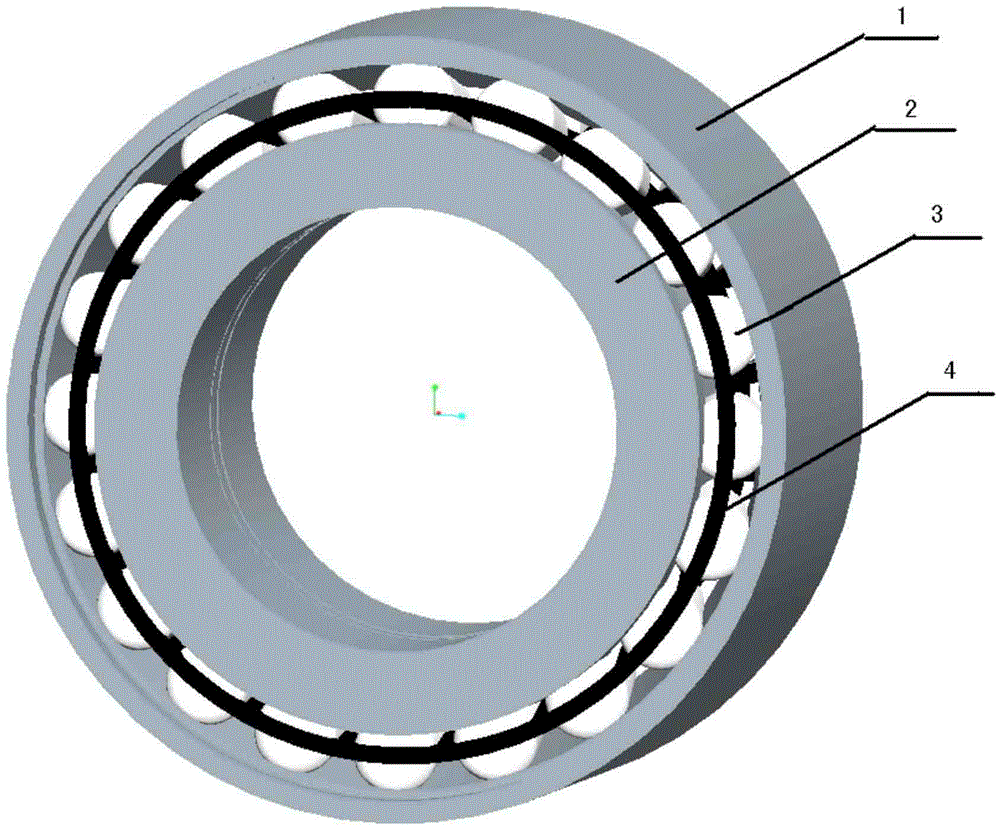

[0024] figure 1 The structure of the train wheel set simulation test bench is given, mainly including wheels (1, 2), shafts (3), bearings (4, 5), motors (6), hydraulic pumps (7), friction wheels (8), Support seat (9); Lance 2052 acceleration sensor (10-13) is deployed on the outside of each rolling bearing; the bearing is driven by a motor to rotate the friction wheel, and the outer ring is relatively stationary; figure 2 The double-row tapered roller bearing (model 197726) used in the experiment with the peeling off of the outer ring and the peeling of the inner ring is given. It consists of an outer ring (1), an inner ring (2), a roller (3), a cage (4 ) and other parts, wherein the number of rollers N=20, roller diameter d=23.7mm, bearing pitch diameter D=180mm, contact angle a=10 degrees, the bearing is accelerated from 50rpm to 240rpm by adjusting the freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com