In-situ regeneration device of SCR catalyst for household garbage burning

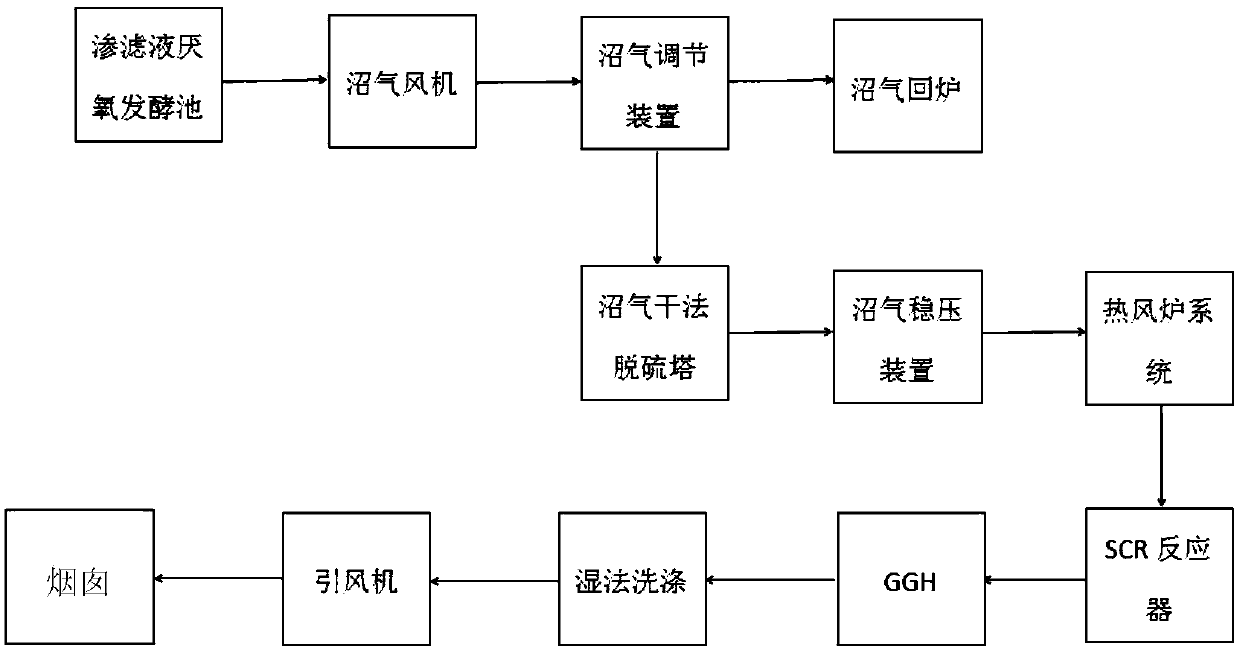

A technology for SCR catalysts and domestic waste incineration, which is applied in catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., and can solve the problem of decreased denitrification efficiency of SCR systems, failure to meet NOx emission requirements, and reduced catalyst service life and other problems, to achieve the effect of saving the cost of use, simplifying the regeneration steps and reducing the regeneration cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

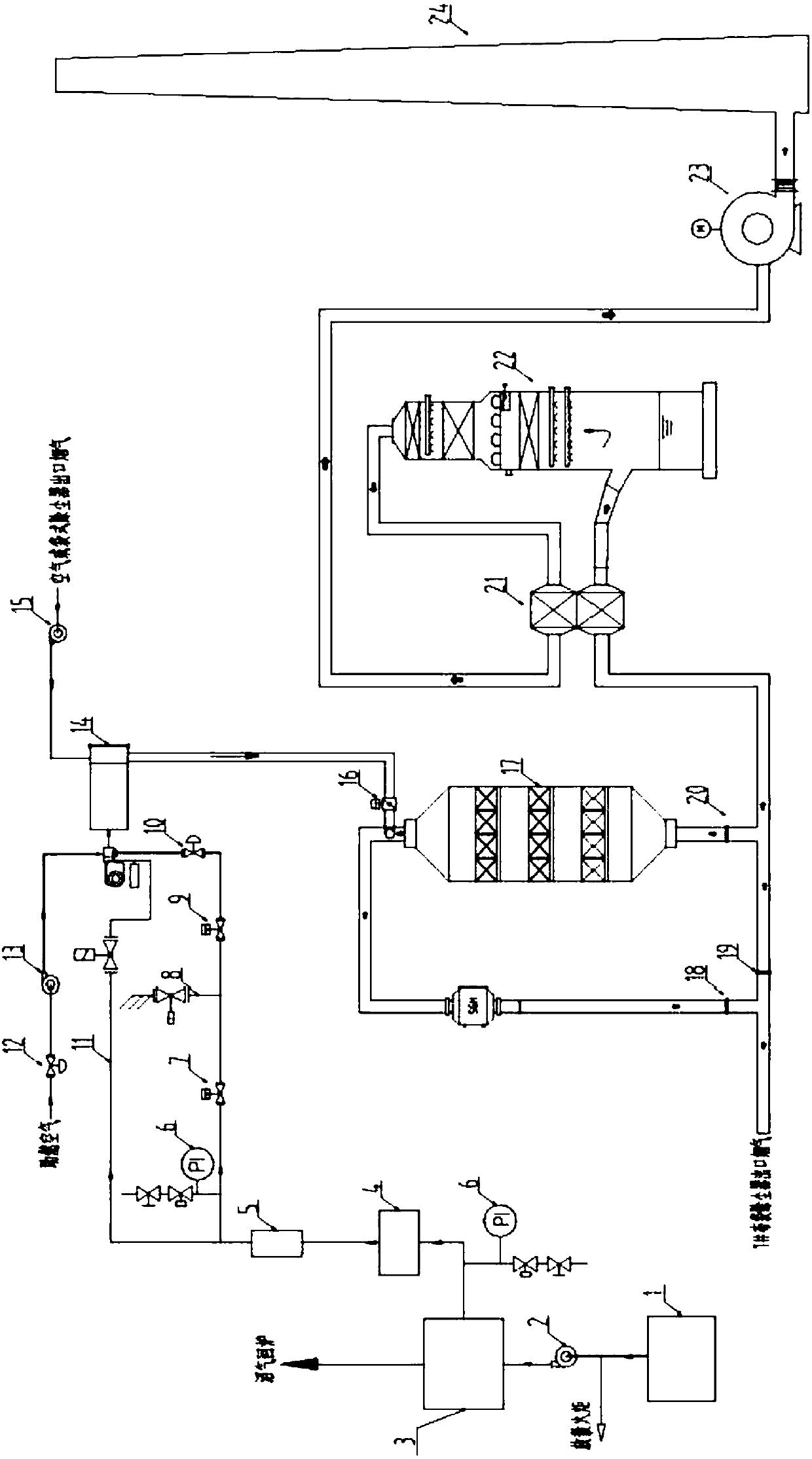

[0029] An in-situ regeneration device for SCR catalysts applied to domestic waste incineration, the schematic diagram of which is shown in Fig. figure 2 As shown, it includes anaerobic fermentation tank 1, biogas fan 2, biogas flow regulating device 3, biogas desulfurization tower 4, biogas pressure regulating device 5, nitrogen replacement device 6, biogas shut-off valve 7, biogas release solenoid valve 8, biogas shut-off valve 9. Biogas control valve 10, ignition burner 11, combustion-supporting air electric control valve 12, combustion-supporting fan 13, hot blast stove 14, secondary fan 15, regenerative flue gas electric valve 16, SCR reactor 17, SCR inlet baffle door 18 , SCR outlet baffle door 20, SCR bypass baffle door, flue gas-flue gas heat exchanger 21, wet scrubber, induced draft fan 23 and chimney 24.

[0030] The upper part of the anaerobic fermentation tank 1 is provided with a biogas outlet, and the bottom is provided with a leachate inlet;

[0031] The mouth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com