Preparation method of diphosphite

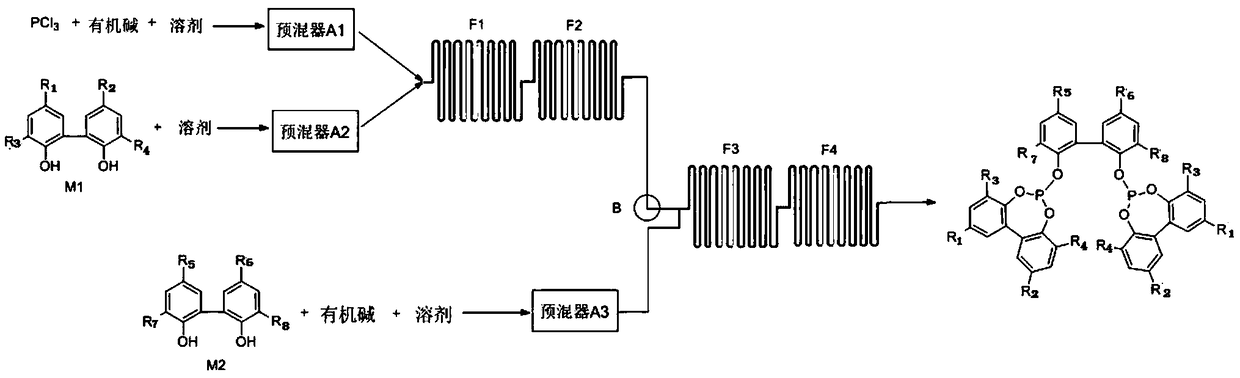

A bisphosphite and phosphorus trichloride technology, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve environmental protection, health and safety problems, and reaction operation steps cumbersome, easy to block the outlet pipe and other problems, to achieve the effect of safe and reliable reaction operation, fast mass transfer and heat transfer, avoiding environmental protection and health and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

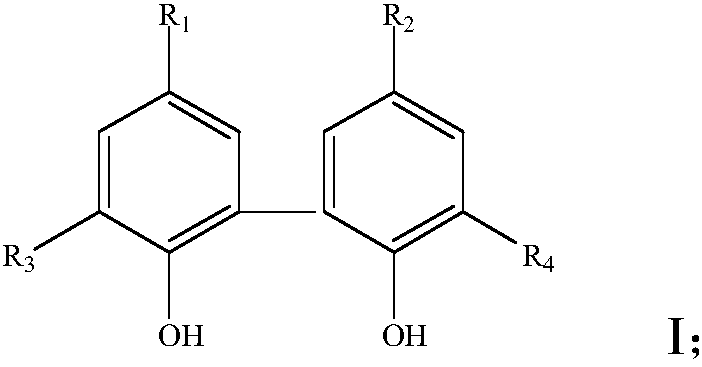

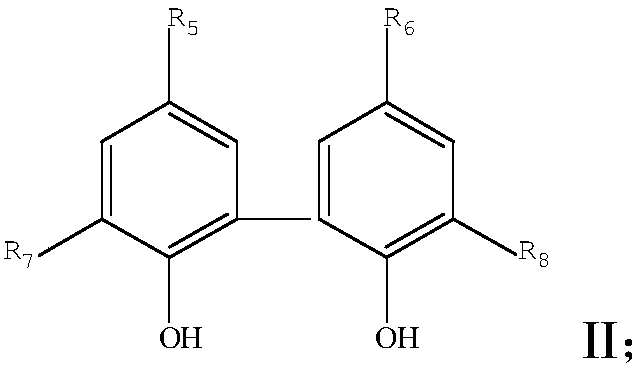

[0059] The following structural formula is the synthesis of bisphosphite bis(2,2'-biphenol)-3,3',5,5'-tetra-tert-butyl-2,2'-biphenolate of the following formula III-1:

[0060]

[0061] (a) Dissolve phosphorus trichloride and pyridine in tetrahydrofuran in the premixer A1, control the concentration of phosphorus trichloride to be 1.5mol / L, and the concentration of pyridine to be 3.1mol / L, adjust the premixer by metering pump The flow rate of A1 is 10mL / min; 2,2'-biphenol is dissolved in tetrahydrofuran in the premixer A2, and the flow rate of the premixer A2 is adjusted to 10mL / min by a metering pump; The raw material is injected into the continuous flow reaction module F1 through a metering pump, keeping the temperature at 20°C, and the residence time is 10 minutes; then flows into the reaction module F2, keeping the temperature at 90°C, and the residence time is 8 minutes, and enters module B to cool after the reaction is completed.

[0062] (b) In premixer A3, dissolve 3...

Embodiment 2

[0066] The following structural formula is bisphosphite bis(2,2'-biphenol)-3,3'-di-tert-butyl-5,5'-dimethoxy-2,2'-biphenol of the following formula III-2 Synthesis of esters:

[0067]

[0068] (a) Dissolve phosphorus trichloride and pyridine in 2-methyltetrahydrofuran in the premixer A1, control the concentration of phosphorus trichloride to be 1.8mol / L, and the concentration of pyridine to be 3.8mol / L, through the metering pump Adjust the flow rate of premixer A1 to 12mL / min; dissolve 2,2'-biphenol in 2-methyltetrahydrofuran in premixer A2, and adjust the flow rate of premixer A2 to 12mL / min through a metering pump; Inject the raw materials in the above two premixers into the continuous flow reaction module F1 through the metering pump, keep the temperature at 15°C, and stay for 15 minutes; then flow into the reaction module F2, keep the temperature at 80°C, and stay for 10 minutes, and enter the module after the reaction B cools down.

[0069] (b) In premixer A3, 3,3'-d...

Embodiment 3

[0073] The following structural formula is the synthesis of bisphosphite bis(3,3'5,5'-tetra-tert-butyl-2,2'-biphenol)-2,2'-biphenolate of the following formula III-3:

[0074]

[0075] (a) Dissolve phosphorus trichloride and triethylamine in 2-methyltetrahydrofuran in premixer A1, control the concentration of phosphorus trichloride to be 1.2mol / L, and the concentration of triethylamine to be 2.5mol / L , adjust the flow rate of premixer A1 to 11mL / min through a metering pump; dissolve 3,3'5,5'-tetra-tert-butyl-2,2'-biphenol in 2-methyl In tetrahydrofuran, adjust the flow rate of the premixer A2 to 11mL / min through the metering pump; inject the raw materials in the above two premixers into the continuous flow reaction module F1 through the metering pump, keep the temperature at 20°C, and the residence time for 20min; then flow into the reaction In module F2, the temperature is maintained at 80°C, and the residence time is 15 minutes. After the reaction is completed, it enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com