Continuous light chemical reaction apparatus, system and continuous preparation method of propellane carbonylation reaction

A technology for photochemical reaction and chemical reaction, applied in the field of photochemical reaction, can solve the problems such as the product cannot be exported in time, the amplification effect is obvious, and the heat exchange is difficult, so as to improve the transfer efficiency, improve the reaction efficiency, and shorten the reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

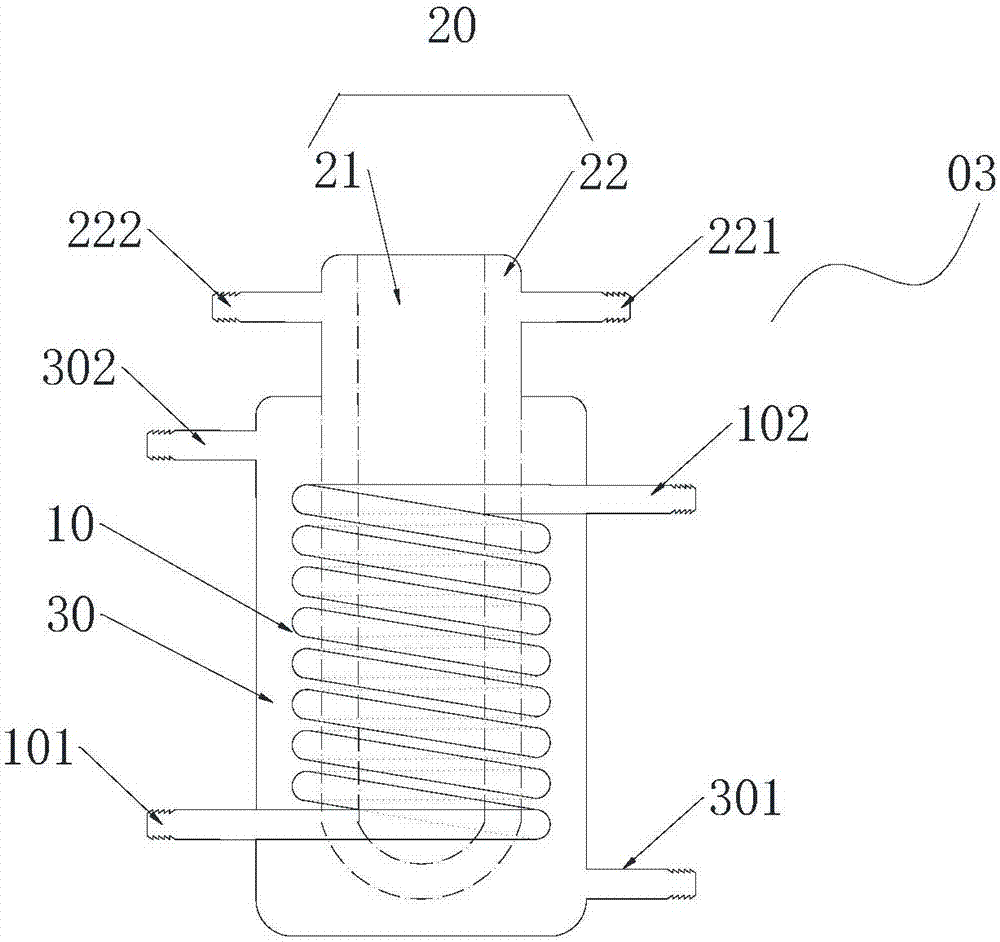

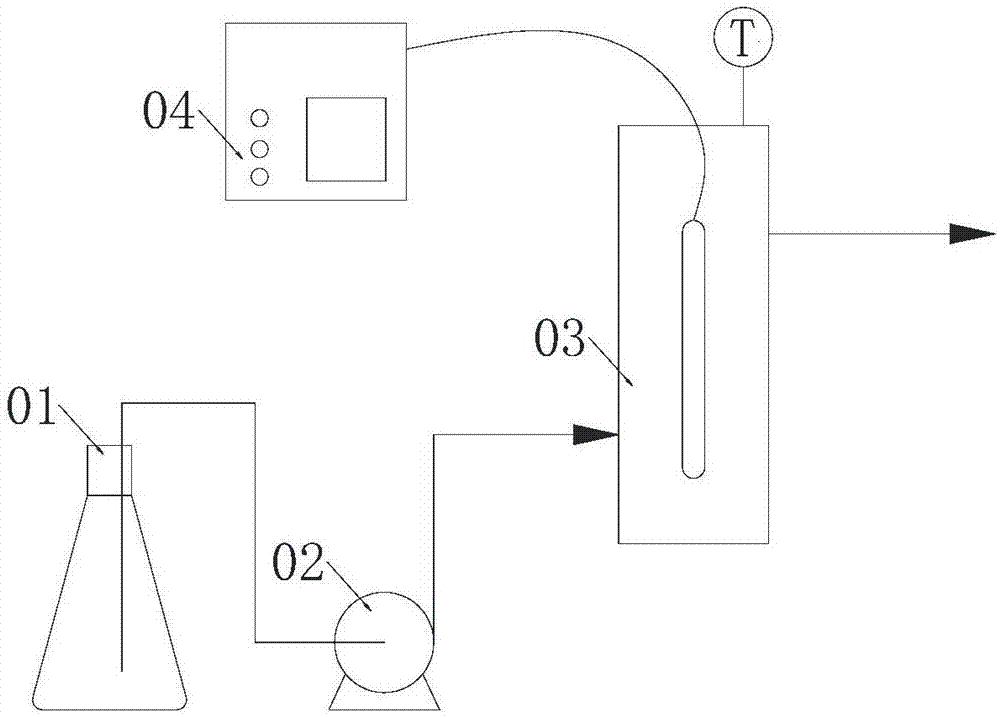

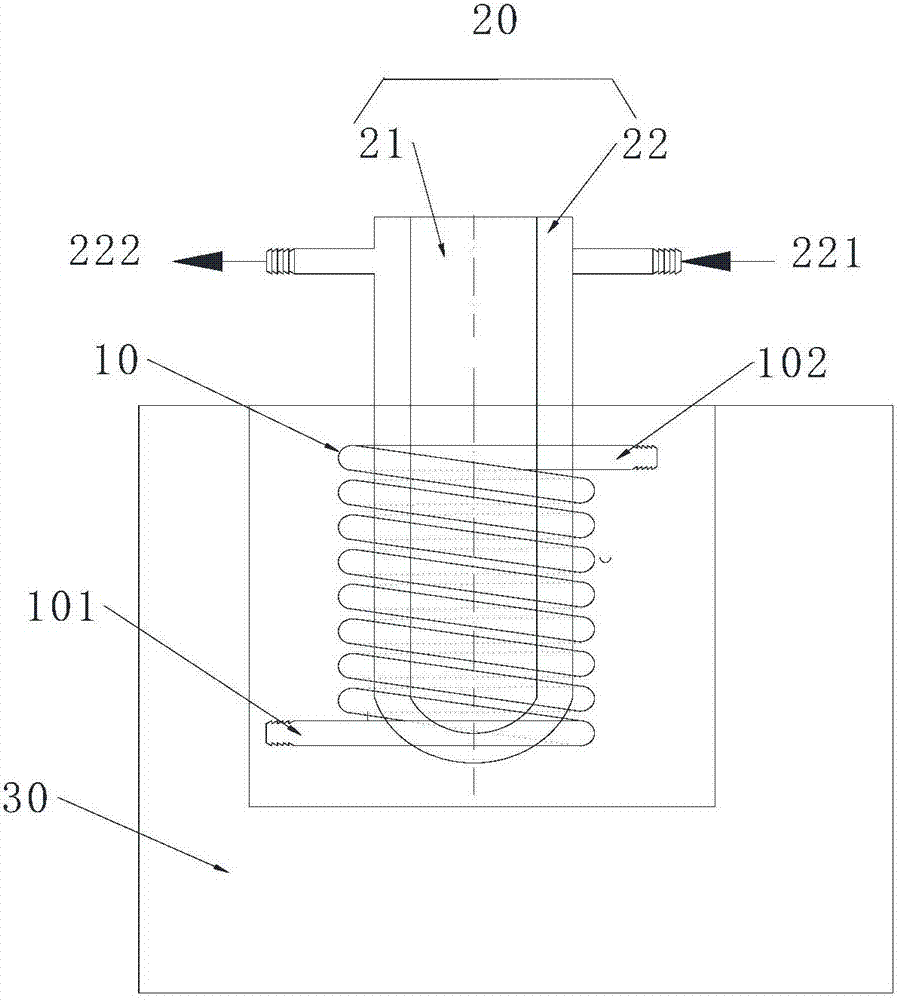

[0050] In the above-mentioned continuous preparation method, a continuous reactor with an appropriate diameter and an appropriate length can be selected for the reaction according to the raw materials to be reacted. In a preferred embodiment of the present application, the continuous reactor in the continuous reaction device is a continuous reaction coil, preferably the diameter of the continuous reaction coil is 2-50 mm; more preferably 2-25 mm, even more preferably 4 mm. When the diameter of the continuous reaction coil is controlled within the above-mentioned preferred range, the reaction can be completed under the irradiation of the same intensity of the irradiation light source.

[0051] In a preferred embodiment of the present application, the time for the continuous reaction is 5-10 minutes; the temperature for the continuous reaction is preferably 20-30°C, more preferably 20-25°C. The continuous reactor of the present application, especially the continuous reaction coi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com