Production method and production system for continuously producing 107 glue with double screws

A production system and production method technology, applied in the production method and production system field of twin-screw continuous production of 107 glue, can solve the problems of poor product molar mass uniformity, viscous and immature reaction objects, etc., and achieve narrow molar mass distribution , High product quality, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

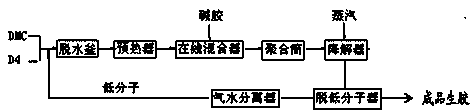

[0029] Such as figure 1 The production system for twin-screw continuous production of 107 rubber shown in the figure starts from the dehydration kettle and connects the preheater, in-line mixer, polymerization cylinder, degrader, delowering device and twin-screw extruder in sequence, among which dehydration Molecular device is also connected with gas-water separator, and described gas-water separator is connected with dehydration still, and described connection is the pipeline connection with valve, and described dehydration still, in-line mixer and degrader are provided with feeding port, so The above-mentioned twin-screw extruder is also connected with a packaging machine, the feeding port of the dehydration kettle is for feeding raw materials, the feeding port of the online mixer is for feeding catalyst, and the feeding port of the described explainer is for feeding water steam.

[0030] The method of production is as follows:

[0031] S1. Introduce the dimethylcy...

Embodiment 2

[0038] Such as figure 1 The production system for twin-screw continuous production of 107 rubber shown in the figure starts from the dehydration kettle and connects the preheater, in-line mixer, polymerization cylinder, degrader, delowering device and twin-screw extruder in sequence, among which dehydration Molecular device is also connected with gas-water separator, and described gas-water separator is connected with dehydration still, and described connection is the pipeline connection with valve, and described dehydration still, in-line mixer and degrader are provided with feeding port, so The above-mentioned twin-screw extruder is also connected with a packaging machine, the feeding port of the dehydration kettle is for feeding raw materials, the feeding port of the online mixer is for feeding catalyst, and the feeding port of the described explainer is for feeding water steam.

[0039] The method of production is as follows:

[0040] S1. Introduce the dimethylcy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com