Method for separating and purifying phage in phage lysate by two-step salting-out extraction

A phage and lysate technology, applied in the field of bioengineering, can solve the problems of phage separation and purification that have not been reported, and achieve good industrial application prospects, shorten operation time, and improve purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Preparation method of phage crude lysate: Klebsiella pneumoniae S2 and phage phiKpS2 were cultured in LB medium (10g / L tryptone, 5g / L yeast extract powder, 10g / L NaCl) and shake flasks for 5-6h Mix according to a certain ratio, and shake flask culture at 37°C and 200rpm. By adjusting the multiplicity of infection (MOI) or co-cultivation time, the crude lysate of phage with different titers can be obtained. The titer of phage, protein concentration , bacteria content and endotoxin content were 10 6 -10 11 pfu / mL, 4-800μg / mL, 10 4 -10 6 cfu / mL, 1.2×10 4 -1.4×10 5 EU / mL.

[0032] 2. Analysis method

[0033] (1) Phage titer determination method:

[0034] Phage titer (Plaque Form Unit) refers to the number of phages in a unit volume sample, which is determined by single-layer agar plate method (spot). Add 1mL of the logarithmic phase host bacterial suspension to the prepared single-layer LB solid medium, spread the bacterial suspension evenly on the solid medium, abs...

Embodiment 1

[0040] The preparation of embodiment 1 phage crude lysate

[0041] Take the Klebsiella pneumoniae KpS2 stored at -20°C, inoculate it in fresh LB medium according to the inoculation amount of 1% (v / v), culture it on a shaker at 37°C and 200rpm for 5-6 hours, and then obtain the logarithmic phase Host bacteria (10 8 -10 9 cfu / mL), and 10 9 The pfu / mL phiKpS2 phage suspension was mixed according to a certain multiplicity of infection (MOI, the number of phages / the number of host bacteria), and then added to fresh LB medium for infection and culture for 2.5-6 hours. In this way, crude lysates of phages with different titers can be obtained, such as a phage titer of 10 6 -10 11 pfu / mL with a total protein content of 400-800 μg / mL and a bacterial concentration of 10 4 -10 6 cfu / mL, endotoxin concentration is 1.2×10 4 -1.4×10 5 EU / mL, pH7.2 or so.

Embodiment 2

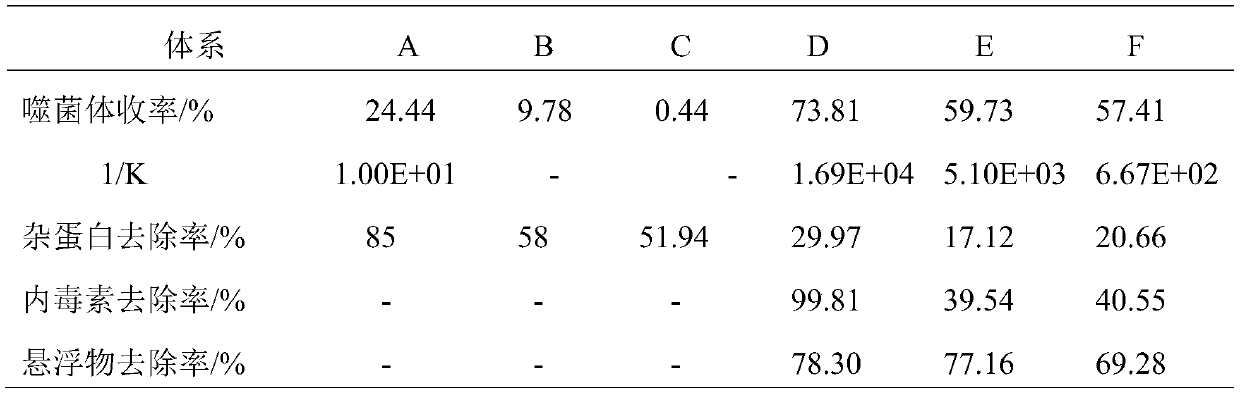

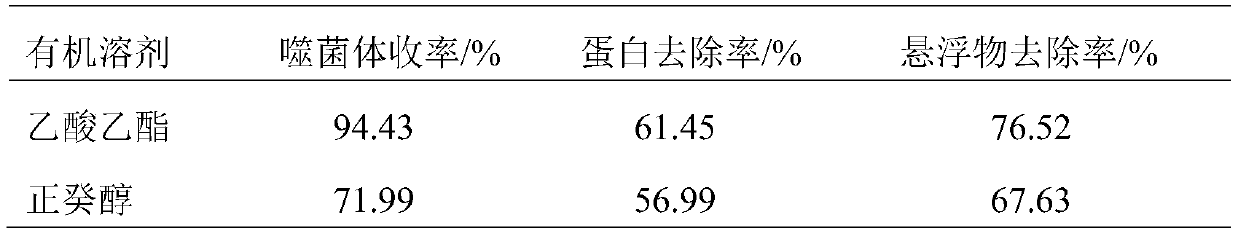

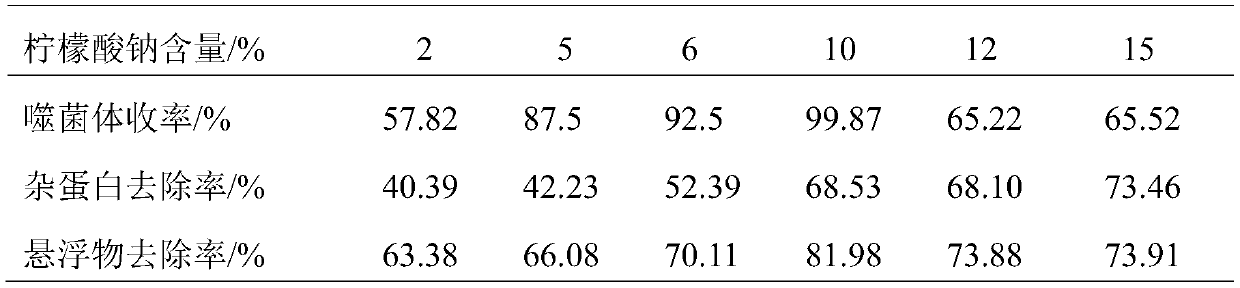

[0042] The separation effect of embodiment 2 different organic solvents-dipotassium hydrogen phosphate salting-out extraction system

[0043] The crude lysate of phage that adopts embodiment 1 to make, phage titer is 10 9 pfu / mL, total protein content is 526 μg / mL, OD 650 =0.462, the bacterial concentration is 4×10 5 cfu / mL, the endotoxin concentration is 1.2×10 5 EU / mL, pH7.3. At room temperature of 16°C, add 5.0%, 5.3% and 19.7% of dipotassium hydrogen phosphate to the 50mL centrifuge tube containing the crude lysate of the phage, and gently vortex to mix the salt completely. The total mass of the system is 47.3% of butyl acetate, 44.4% of methyl tert-butyl ether and 35.7% of ethanol, respectively forming three kinds of organic solvents A, B and C - dipotassium hydrogen phosphate salting-out extraction system, centrifuged at 2000g for 10min Accelerate into phase. Take 200 μL of the upper and lower phases, and take out all the agglutinated intermediate phases and dilute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com