Narrow trench manufacturing method

A fabrication method and trench technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0017] Figure 5 to Figure 9 Each step of the method for fabricating a narrow trench according to a preferred embodiment of the present invention is schematically shown.

[0018] Specifically, such as Figure 5 to Figure 9 As shown, the narrow trench fabrication method according to a preferred embodiment of the present invention includes:

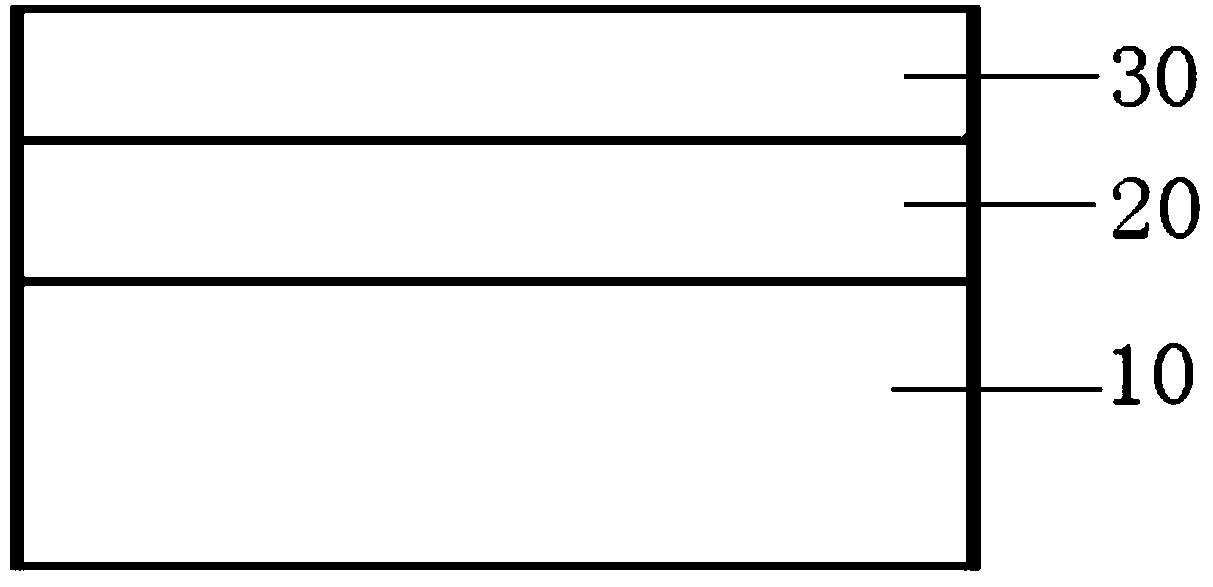

[0019] The first step is for sequentially arranging a silicon nitride layer 2 and a hard mask 3 on a semiconductor substrate 1;

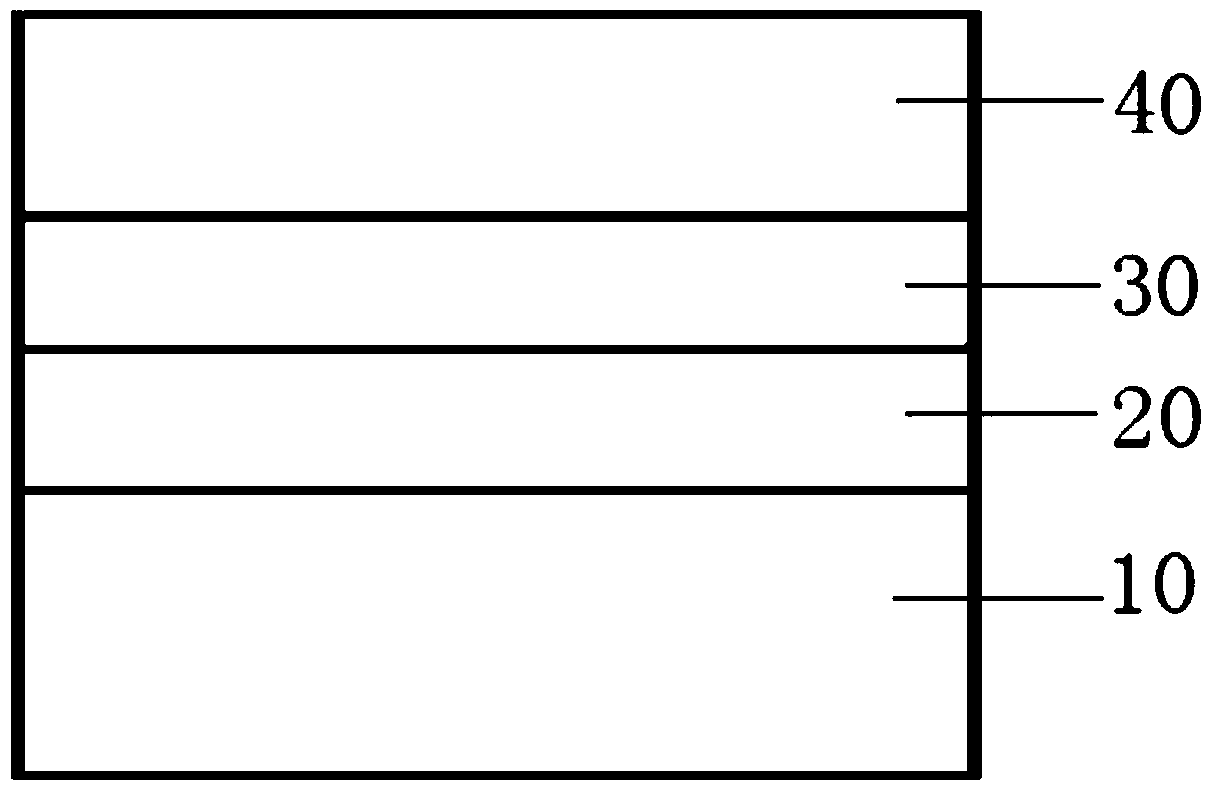

[0020] The second step is for arranging photoresist 4 on hard mask 3;

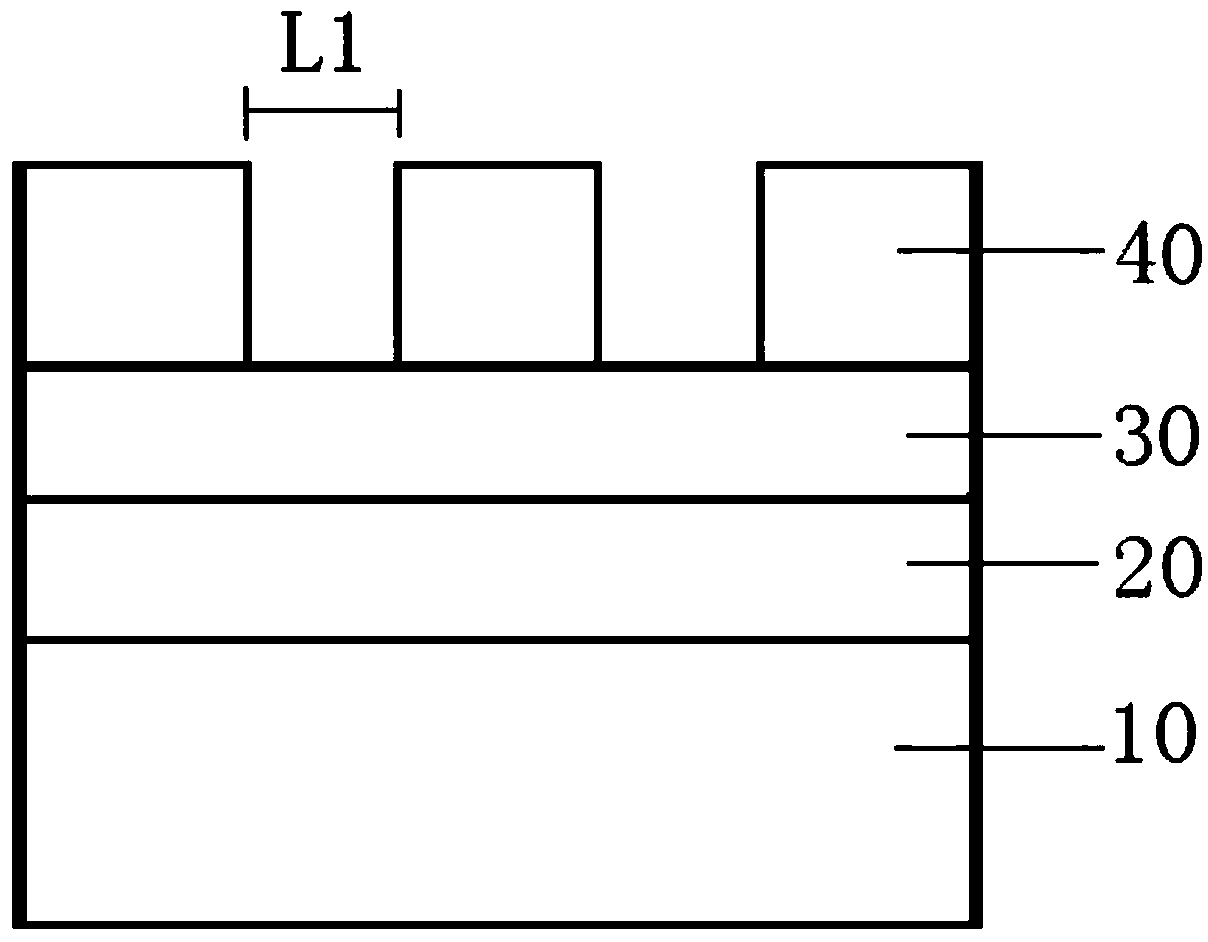

[0021] The third step is to expose and develop the photoresist 4 to form a photoresist pattern with a first size L1;

[0022] The fourth step is to carry out ion implantation (such as Figure 8 Shown by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com