Measuring apparatus for frictional moment of bearing under different axial loads and rotation speeds

An axial load and friction torque technology, which is used in measuring devices, torque measurement, power measurement, etc., can solve the problems that it cannot be used to measure the dynamic friction torque of bearings, cannot be used to measure dynamic friction torque, and cannot be widely promoted and applied. , to achieve the effect of simple structure, easy production and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

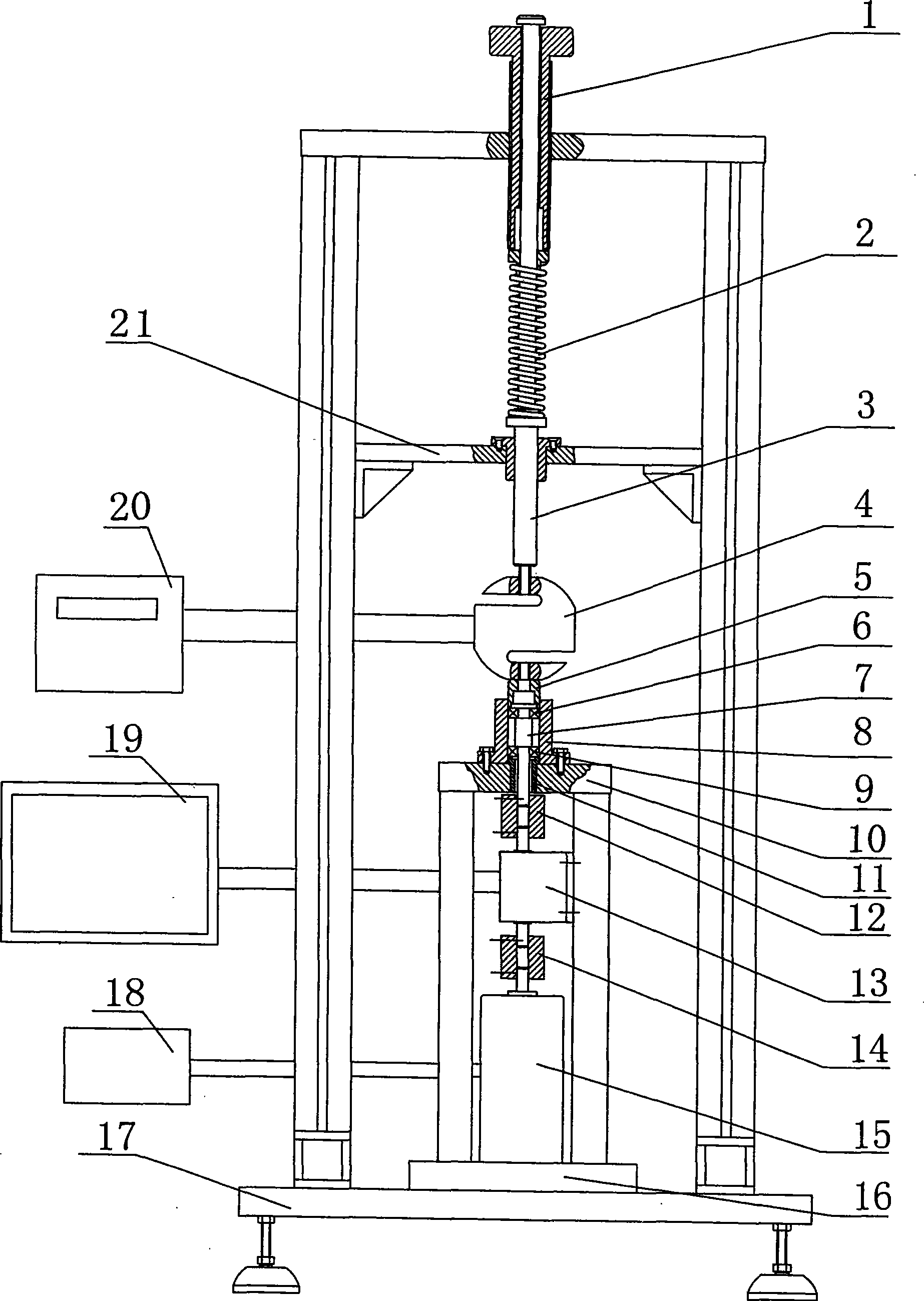

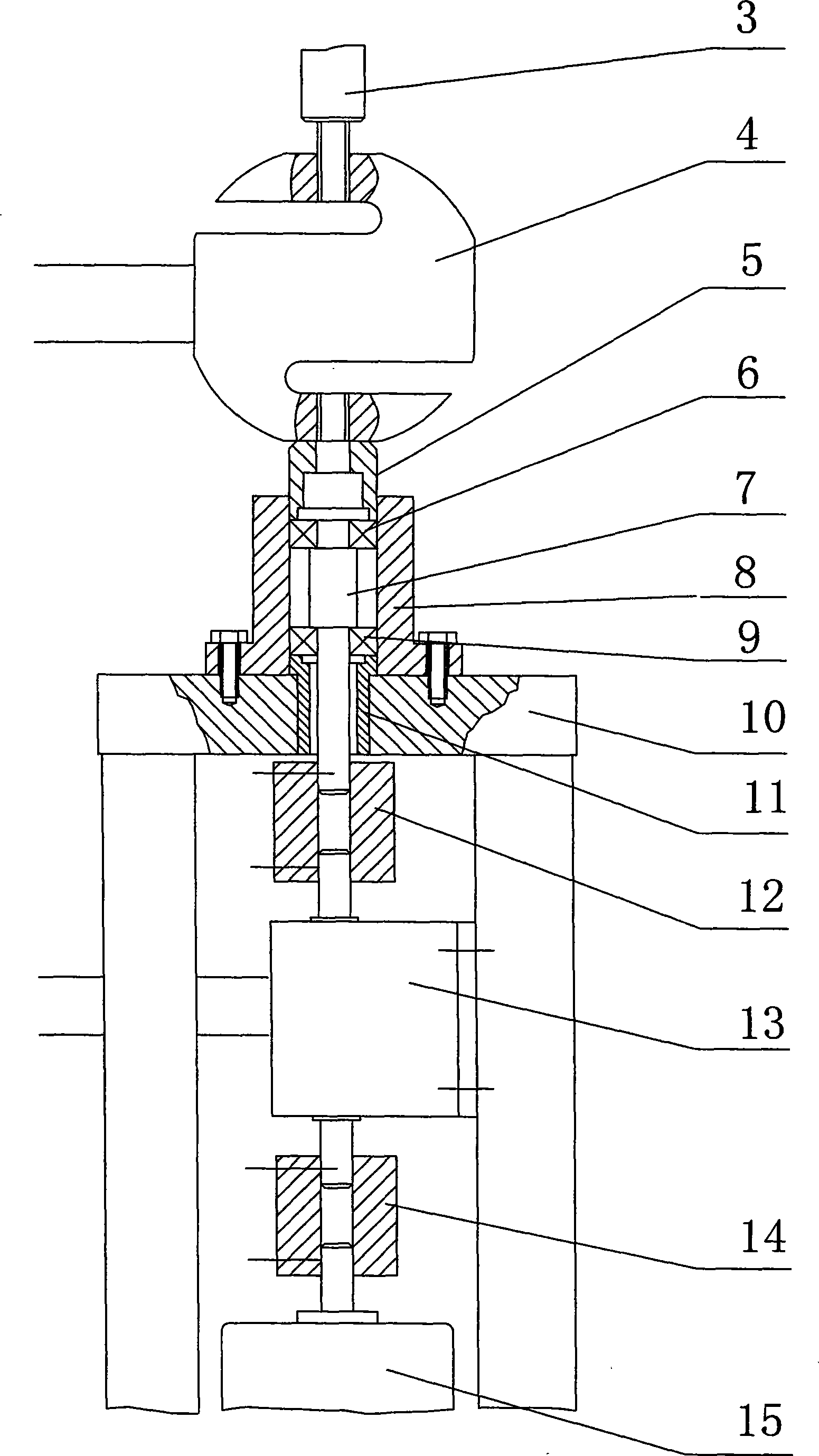

[0013] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0014] DC motor 15 and workbench 10 are fixed on the base plate 16 with screws, and base plate 16 is fixed on the base 17 of the frame with screws, and DC motor 15 is connected with voltage regulator 18 to form a fixed assembly.

[0015] The screw rod 1 is connected with the loading rod 3 as a whole, and the lower end of the screw rod is also covered with a spring 2, and the loading rod 3 passes through the through hole on the rack rail 21, and is fixed to the screw hole at the upper end of the gravity transmitter 4 with the screw thread at the lower end of the loading rod 3 The loading head 5 is connected to the screw hole at the lower end of the gravity sensor 4, and the gravity sensor 4 is also connected to the load gauge 20 to form an axial loading assembly.

[0016] Two bearings of the same type and specification are used for the tested be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com