Method and apparatus for spinning fabrics

a technology of spinning fabrics and fabrics, applied in the field of spinning fabrics, can solve problems such as damage to the boot seal, and achieve the effect of lower than the desired rotational speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

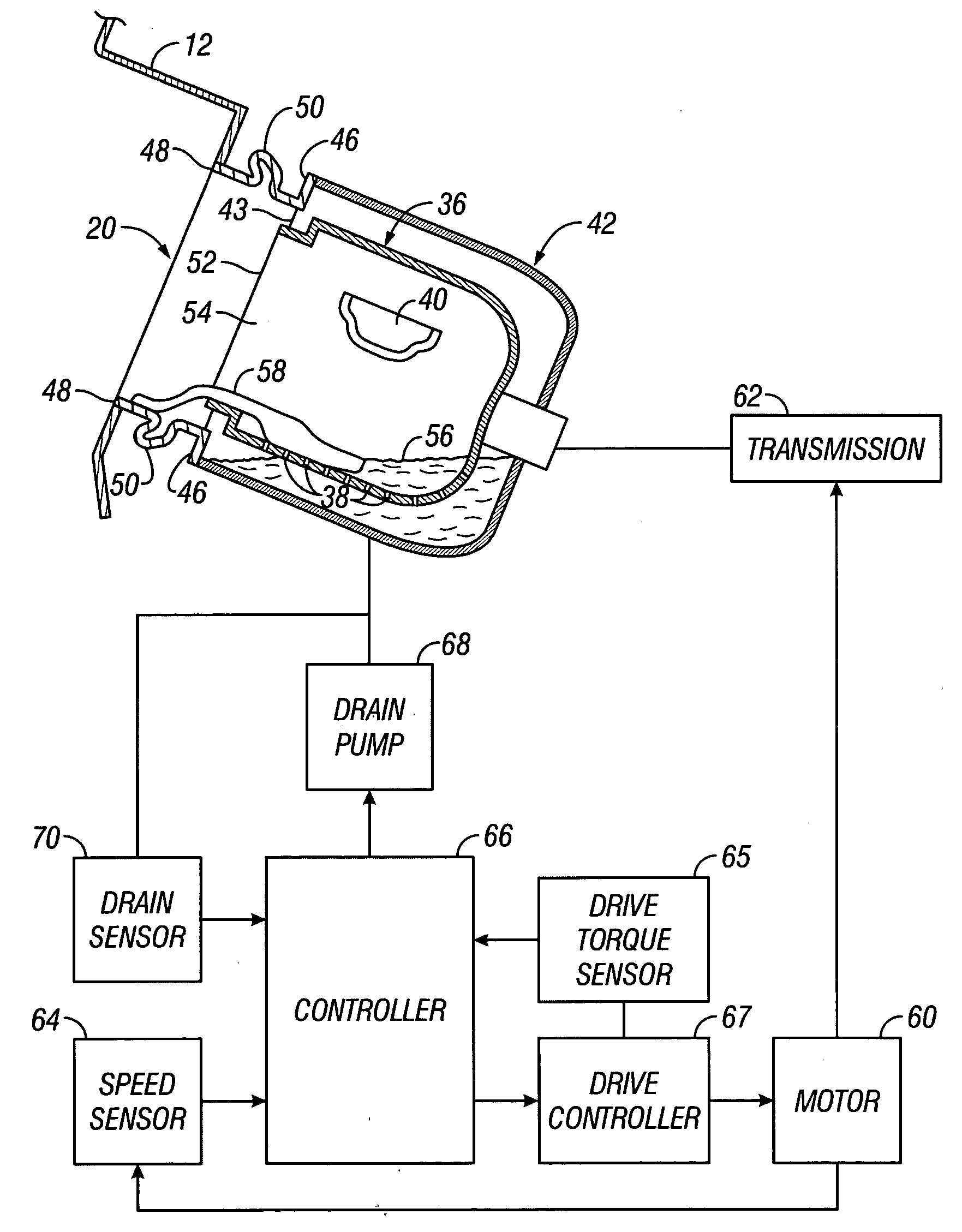

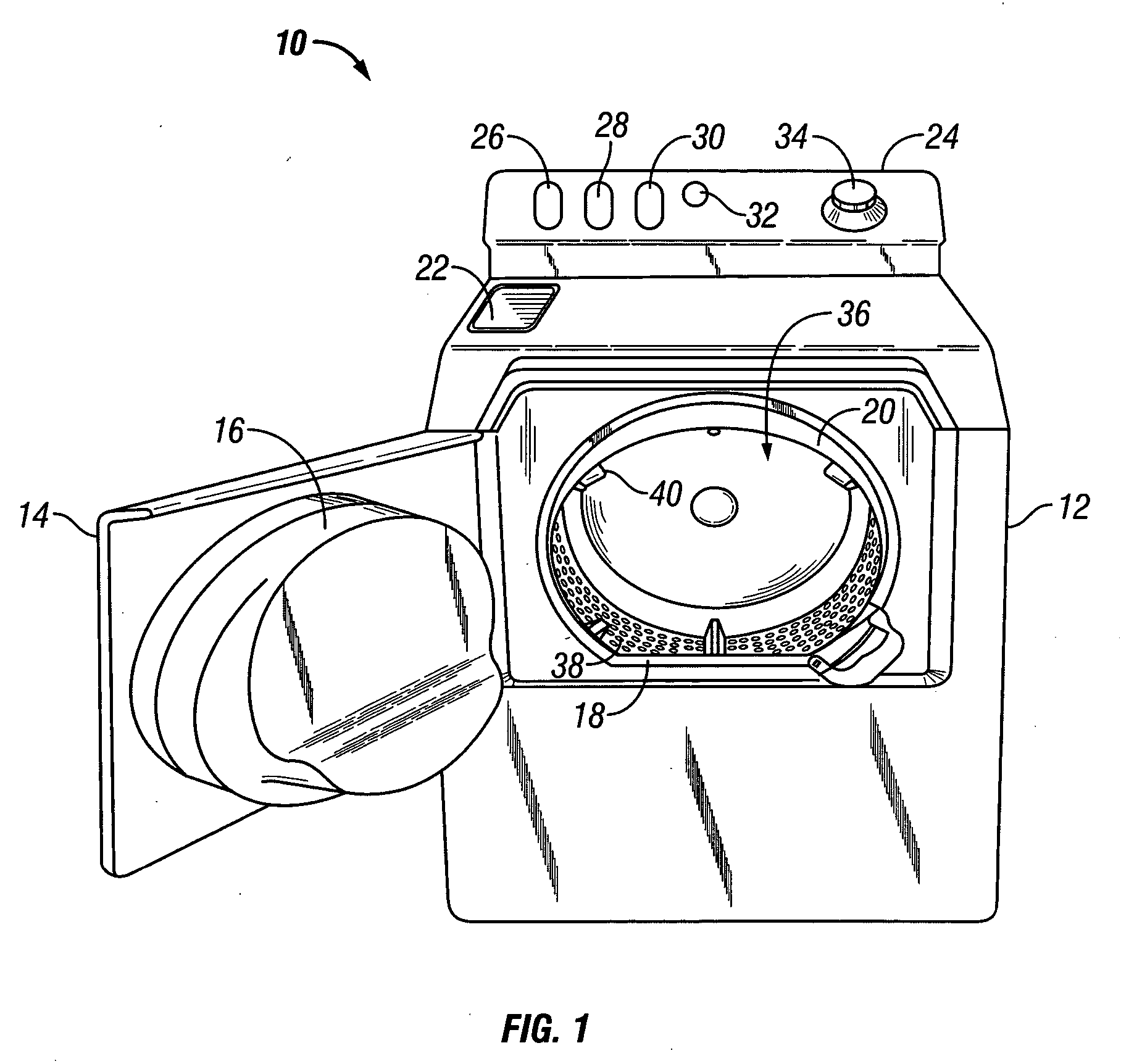

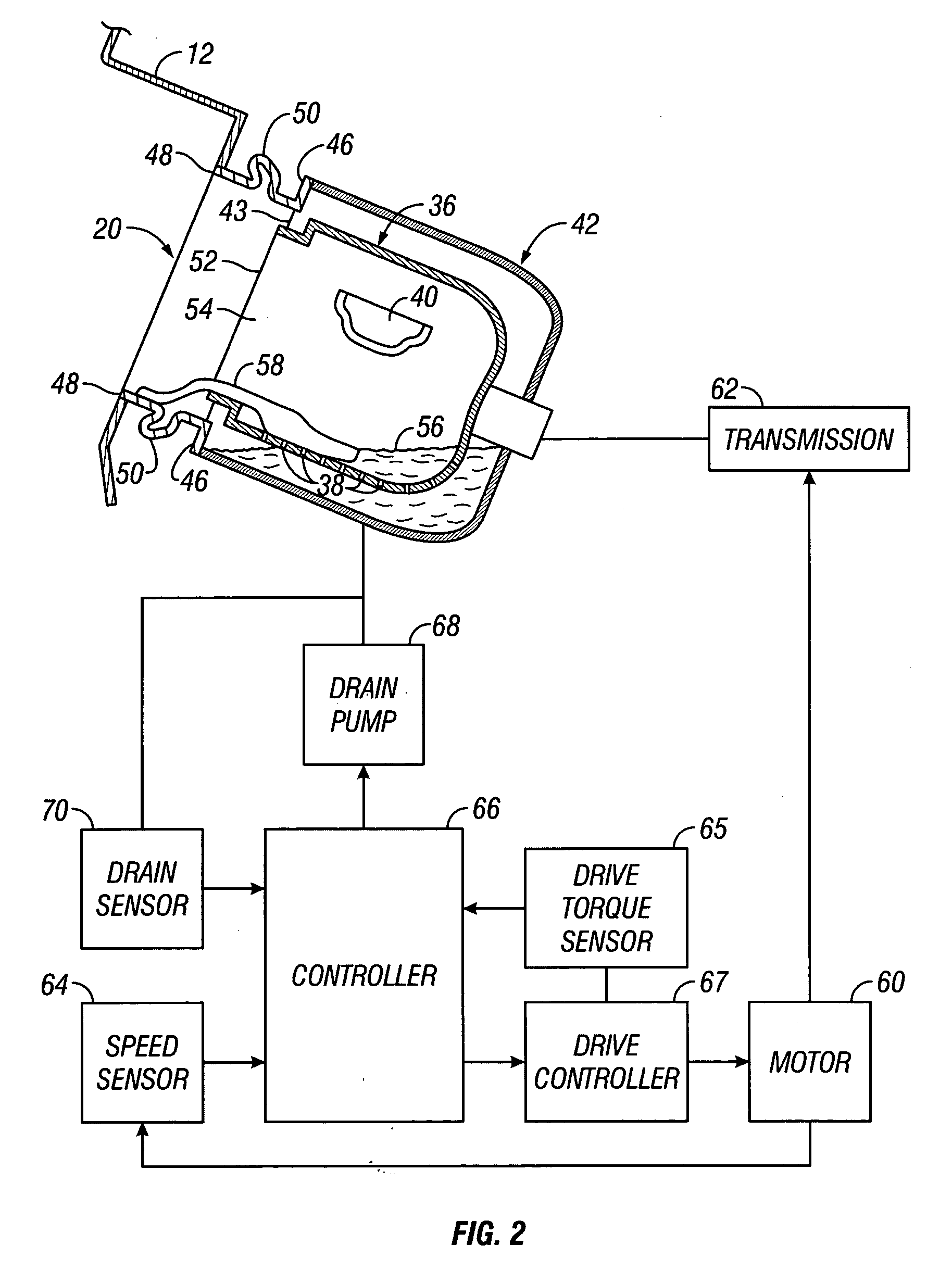

[0025] Referring to the drawings, the numeral 10 generally designates a washing machine made according to the present invention. Washing machine 10 includes a cabinet 12 having a front door 14. The front door 14 includes a nose 16 which projects inwardly when the door is closed. The door is hinged to close over an access opening 18 having a boot seal 20 surrounding the access opening 18.

[0026] A detergent dispenser 22 is provided in the top of the washing machine 10 for introducing detergents and the like to the interior of the washing machine 10. Washing machine 10 also includes a control panel 24 having selector buttons 26, 28, 30, and 32. The control panel 24 also includes a control knob 34.

[0027] Mounted for rotation within the cabinet 12 is a wash basket 36 having holes 38 in its peripheral wall. Wash basket 36 also includes a plurality of fins or blades 40 protruding inwardly from its peripheral wall for tumbling the fabrics within the washing basket 36 during the time that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com