Passive fan assembly

a passive fan and fan body technology, applied in the direction of machines/engines, stators, liquid fuel engines, etc., to achieve the effect of effectively using airflow and promoting heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

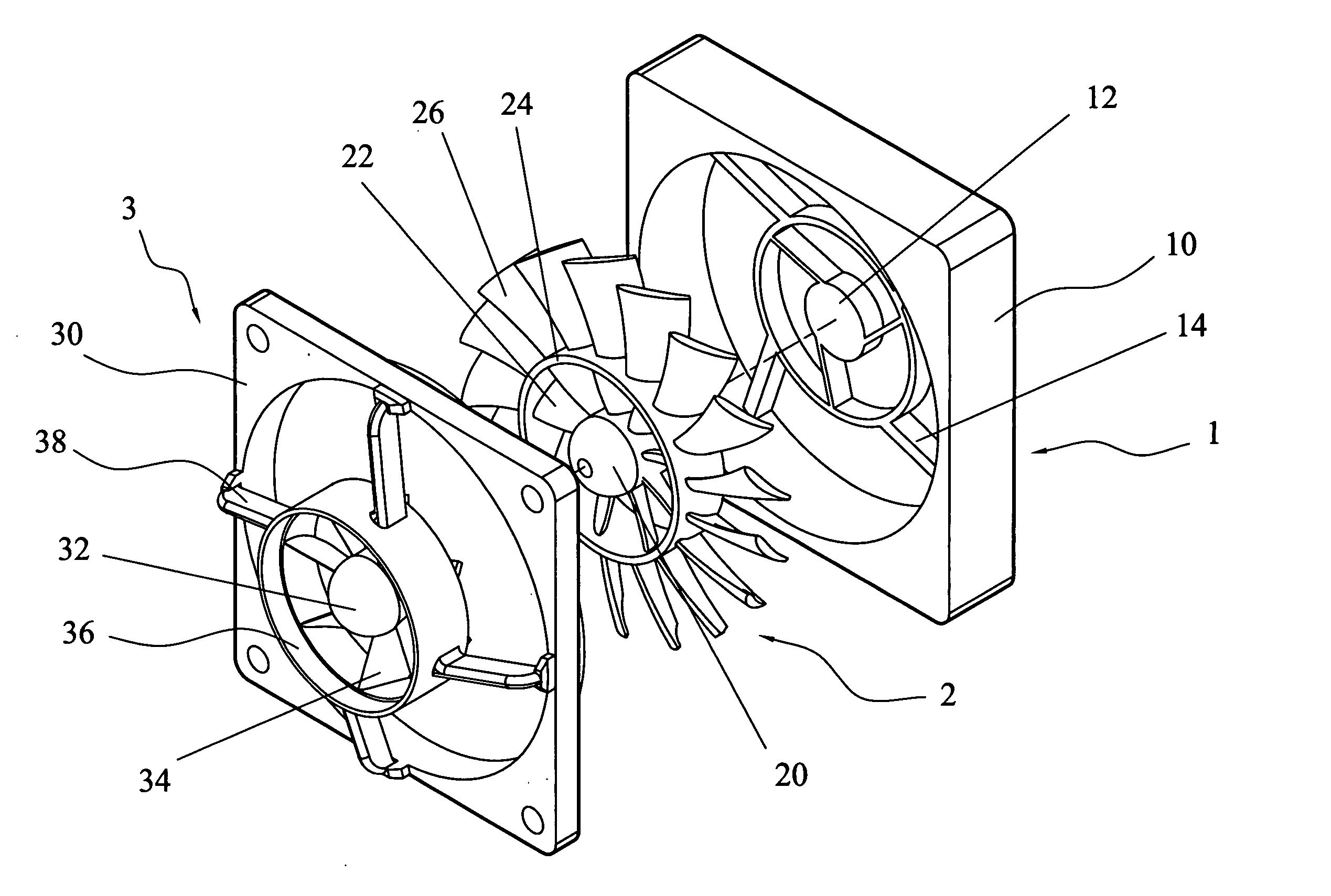

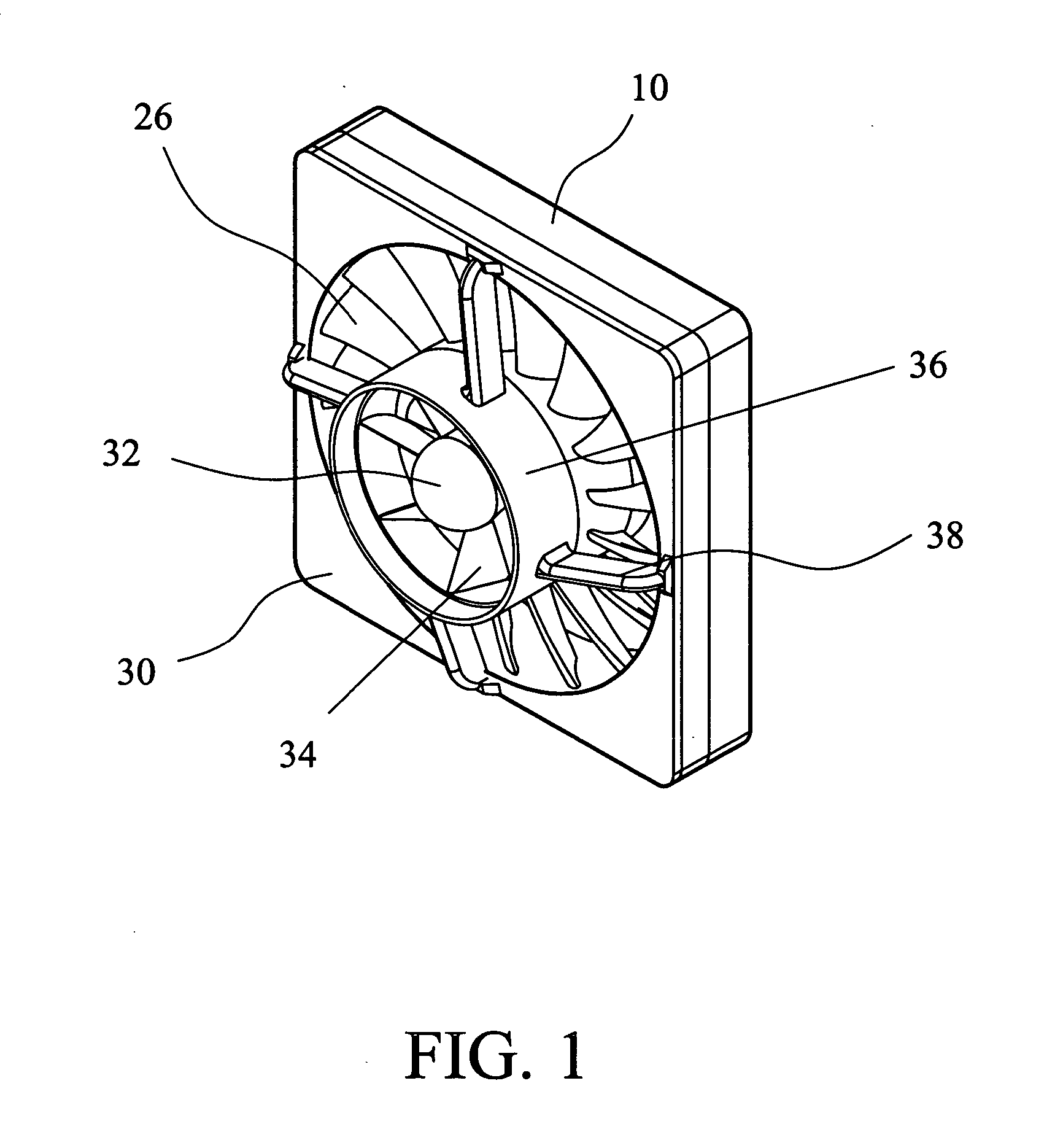

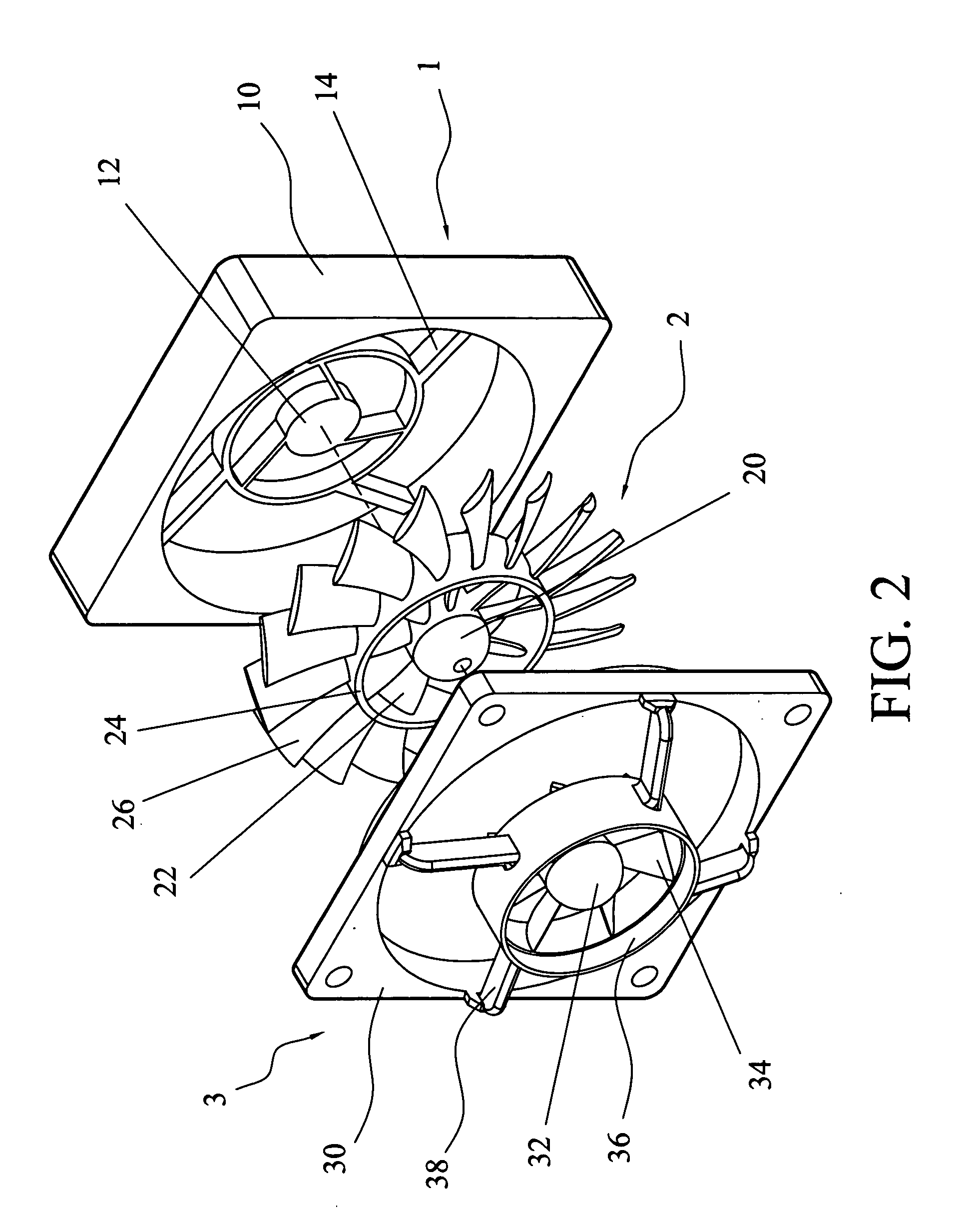

[0019] Referring to FIGS. 1, 2 and 4, a passive fan assembly in accordance with an embodiment of the invention includes a base 1, an impeller 2 mounted on the base 1, and a cover 3 disposed in front of the impeller 2 and connected to the base 1.

[0020] The impeller 2 includes a hub 20, a plurality of runner blades 22 encircling the hub 20, a partition 24 connected to ends of the runner blades 22, a plurality of active blades 26 encircling the partition 24, and a rotary shaft 28 axially extending from the hub 20.

[0021] The base 1 includes a frame 10, a bearing seat 12, a plurality of ribs 14 connecting the frame 10 and the bearing seat 12, and at least one bearing 16 disposed in the bearing seat 12 for holding the rotary shaft 28 of the impeller 2. The bearing 16 may be a bushing bearing, a ball bearing, a magnetic bearing or any other bearing in which the rotary shaft 28 can be stably rotated. Furthermore, a plurality of airflow-guiding blades can be substituted for the ribs 14 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com