Particle size gradation coal blending method capable of improving strength of briquetted activated carbon

A technology of activated carbon and strength, applied in the field of coal chemical industry, can solve the problems of low strength of finished products, poor strength of briquette activated carbon, low degree of coalification, etc., and achieve the effect of improving molding compactness, meeting market demand, and improving strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

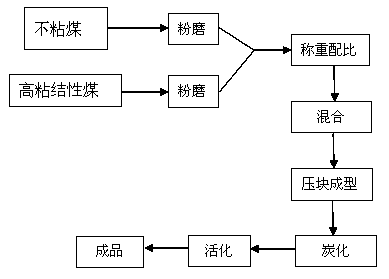

[0023] A particle graded coal blending method for improving the strength of briquetted activated carbon, comprising the steps of:

[0024] (1) Grinding. The above-mentioned Xinjiang non-stick coal and fat coal are selected for grinding respectively. The particle size of non-stick coal after grinding is controlled at 325 mesh, and the particle size of fat coal after grinding is controlled at 400 mesh or 800 mesh;

[0025] (2) Weigh the proportion, add 10% pulverized fat coal (400 mesh) or 5% pulverized fat coal (800 mesh) to the pulverized non-caking coal, and stir until well mixed;

[0026] (3) Briquetting forming, sending the mixed pulverized coal into the forming equipment for briquetting;

[0027] (4) Carbonization, put the briquetted coal into the rotary furnace for carbonization;

[0028] (5) Activation: activate the carbonized coal in an activation furnace until the loss on ignition rate reaches 50%, and obtain the finished briquetted activated carbon.

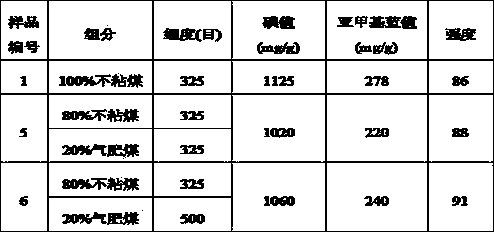

[0029] The br...

Embodiment 2

[0034] A particle graded coal blending method for improving the strength of briquetted activated carbon, comprising the steps of:

[0035] (1) Grinding. The above-mentioned Xinjiang non-stick coal and gas-fertilized coal are selected for grinding respectively. The particle size of the non-stick coal after grinding is controlled at 325 mesh, and the particle size of the gas-fertilizer coal after grinding is controlled at 500 mesh;

[0036] (2) Weigh the proportion, add the pulverized gas fertilizer coal with a weight fraction of 20% to the pulverized non-caking coal, and stir until the mixture is uniform;

[0037] (3) Briquetting forming, sending the mixed pulverized coal into the forming equipment for briquetting;

[0038] (4) Carbonization, put the briquetted coal into the rotary furnace for carbonization;

[0039] (5) Activation: activate the carbonized coal in an activation furnace until the loss on ignition rate reaches 50%, and obtain the finished briquetted activated ca...

Embodiment 3

[0045] A particle graded coal blending method for improving the strength of briquetted activated carbon, comprising the steps of:

[0046] (1) Grinding, the above-mentioned Xinjiang non-stick coal and coking coal are selected for grinding respectively, the particle size of non-stick coal after grinding is controlled at 325 mesh, and the particle size of coking coal after grinding is controlled at 400 mesh;

[0047] (2) Weigh the proportion, add 20% pulverized coking coal into the pulverized non-caking coal, and stir until evenly mixed;

[0048] (3) Briquetting forming, sending the mixed pulverized coal into the forming equipment for briquetting;

[0049] (4) Carbonization, put the briquetted coal into the rotary furnace for carbonization;

[0050] (5) Activation: activate the carbonized coal in an activation furnace until the loss on ignition rate reaches 50%, and obtain the finished briquetted activated carbon.

[0051]Get the briquetting activated carbon sample label of ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com