based on nh 3 Desulfurization method of iron ore shaft furnace pelletizing process with slow-release binder

A binder and shaft furnace technology, applied in the field of iron and steel metallurgy, can solve problems such as high operating costs, increased concentration, and large load on the desulfurization system, and achieve the effects of improving desulfurization efficiency, reducing decomposition speed, and increasing decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

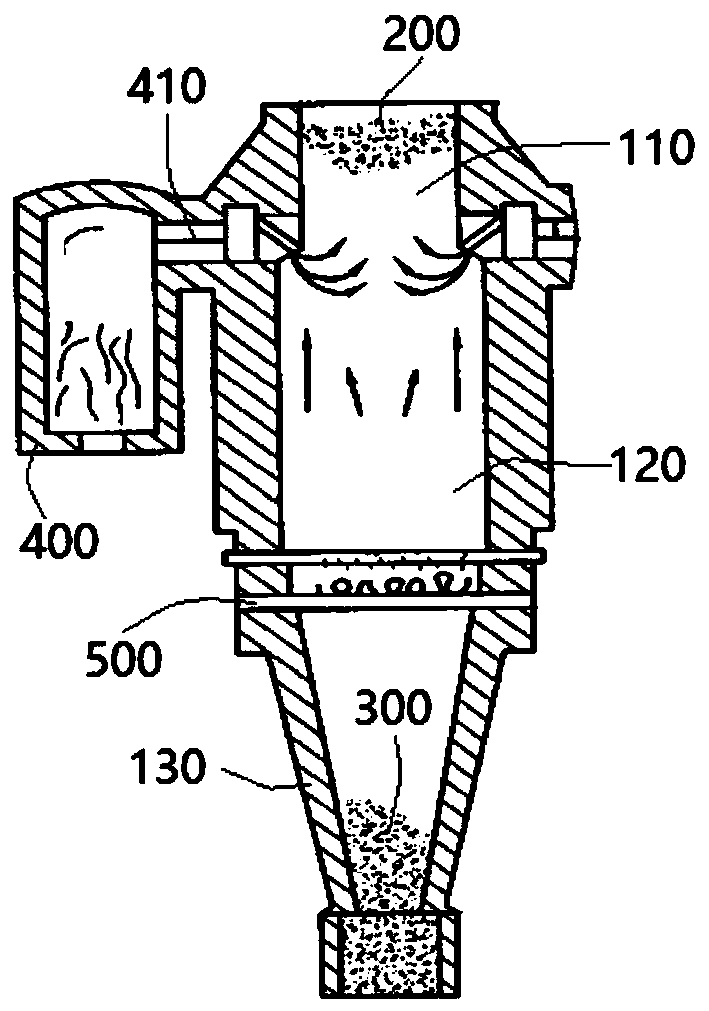

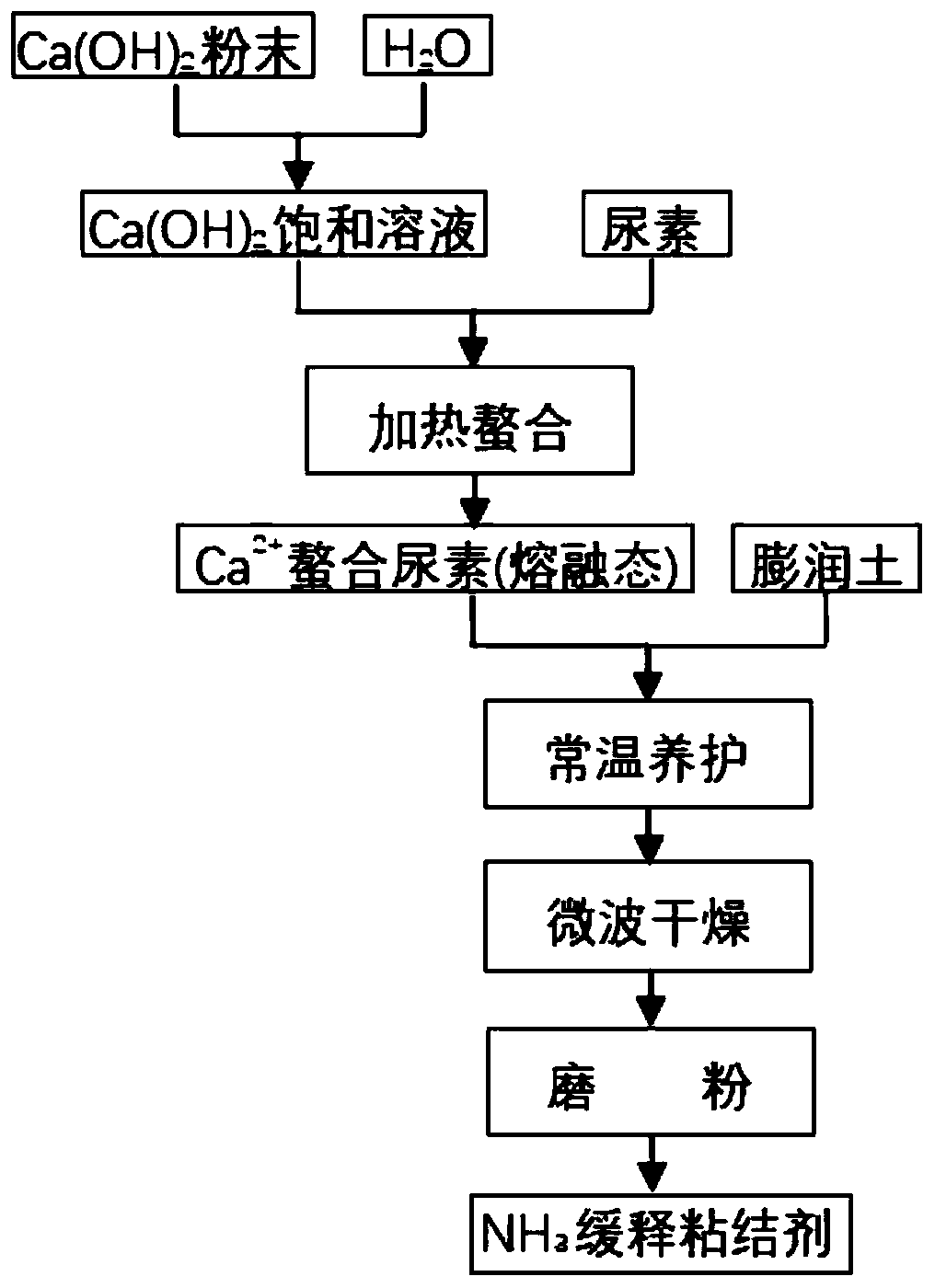

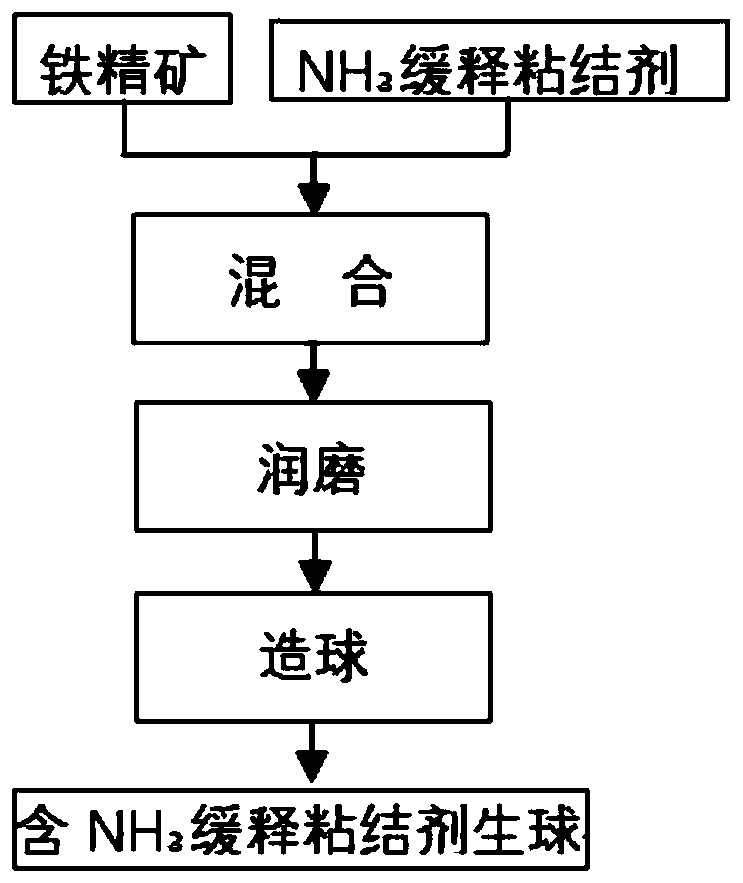

[0045] Such as Figure 1 to Figure 3 As shown, the NH-based 3 Desulfurization method of iron ore shaft furnace pelletizing process with slow-release binder, adding NH in the process of preparing green pellets 200 in iron ore shaft furnace 3 slow-release binder, green balls 200 enter the upper drying section 110 at the upper part of the shaft furnace, the temperature in the upper drying section 110 is 100-300°C, NH 3 Slow release binder releases NH when heated 3 and water vapor, and the SO-containing 2 Exhaust gases mix and react to form NH 4 HSO 4 , (NH 4 ) 2 SO 4 , NH 4 HSO 3 or (NH 4 ) 2 SO 3 , enter the dust in the subsequent dust removal process, that is, enter the flue gas in the form of dust, enrich in the dust removal system, and the SO in the exhaust gas 2 content decreased.

[0046] In this example, if figure 1 As shown, in the production process of shaft furnace pellets, the upper part of the shaft furnace is the upper drying section 110, the lower par...

Embodiment 2

[0068] Add 1% NH to the mixed iron concentrate 3 The slow-release binder is prepared into pellets with a diameter of 10-12mm. The sintering cup is used to simulate the drying, preheating and roasting process of the shaft furnace. The height of the green pellet layer is 50cm, the hot air temperature is 1000℃, and the SO 2 The average concentration in the concentrated discharge area is 812mg / m 3 , The process desulfurization rate reaches 39.85%.

Embodiment 3

[0070] Add 2% NH to the mixed iron concentrate 3 The slow-release binder is prepared into pellets with a diameter of 8-10mm. The sintering cup is used to simulate the drying, preheating and roasting process of the shaft furnace. The height of the green pellet layer is 50cm, the hot air temperature is 1000℃, and the SO 2 The average concentration in the concentrated discharge area is 879mg / m 3 , The process desulfurization rate reaches 34.89%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com