Waterproof material for semi-rigid base surface and preparation method thereof

A semi-rigid base and waterproof material technology, applied in the field of road engineering, can solve the problems of less research on semi-rigid base structure optimization, and achieve the effect of simple preparation conditions and preparation process, strong permeability, and excellent impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment provides a waterproof material for the surface of the semi-rigid base, which consists of the following raw materials in terms of mass fraction: 10% glass flakes, 40% diatomaceous earth, 9% water glass, 10% slag powder, 6% Graphene oxide, 6% sodium cocoyl methyl taurate, 3% polysiloxane defoamer, balance 16% water.

[0034] The glass flakes are medium-alkali glass flakes with a diameter of 0.2-0.4mm, a thickness of 5±2μm, and a density of 2.52g / cm 3 , Barcol hardness is 57.

[0035] Diatomaceous earth is white or off-white, SiO 2 The content is greater than or equal to 98%, and the density is 1.9-2.3g / cm 3 .

[0036] The modulus of water glass is 2.5 and the degree of Baume is 37.

[0037] The slag powder is S105 grade slag powder, and its quality coefficient is 1.86.

[0038] Graphene oxide is in the form of amber powder, with a purity greater than or equal to 99%, a sheet diameter of 0.5-10 μm, one layer, and a single-layer rate greater than...

Embodiment 2

[0048] Embodiment 2: This embodiment provides a kind of waterproof material that is used for semi-rigid base surface, by mass fraction, is made up of following raw material: 15% glass flakes, 32% diatomite, 12% water glass, 8% slag powder, 8% graphene oxide, 4% sodium cocoyl methyl taurate, 2% polysiloxane defoamer, and the balance is 19% water.

[0049] The requirements for each raw material are the same as in Example 1 in this example.

[0050] The preparation method of this example is the same as that of Example 1, and finally a waterproof material for the surface of the semi-rigid base layer is prepared, numbered 2#.

Embodiment 3

[0052] The present embodiment provides a waterproof material for the surface of the semi-rigid base, which consists of the following raw materials in terms of mass fraction: 13% glass flakes, 35% diatomaceous earth, 10% water glass, 9% slag powder, 7% Graphene oxide, 5% sodium cocoyl methyl taurate, 2.5% polysiloxane defoamer, balance 18.5% water.

[0053] The requirements for each raw material are the same as in Example 1 in this example.

[0054] The preparation method of this example is the same as the steps of Example 1, and finally a waterproof material for the surface of the semi-rigid base layer is prepared, numbered 3#.

[0055] Effectiveness analysis:

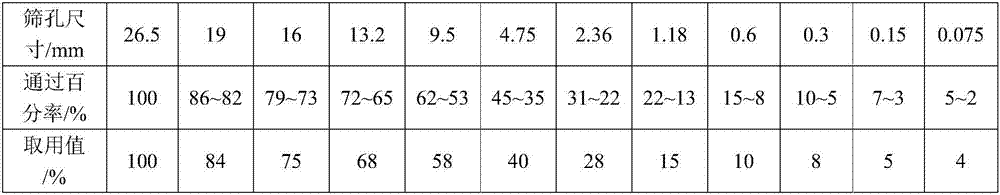

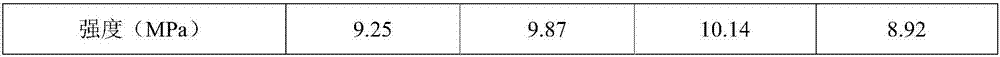

[0056] Firstly, 42.5 ordinary Portland cement is used to prepare cement-stabilized crushed stone semi-rigid base material, and its dosage is 5%. The mineral material gradation is shown in Table 1. Three batches of test pieces were molded separately for unconfined compressive strength test, water permeability test an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com