Fracturing propping agent composition, fracturing propping agent, and preparation method thereof

A fracturing proppant and composition technology, applied in the field of fracturing proppant and fracturing proppant composition, can solve the problems of complex fly ash treatment, high cost of raw material formula, complicated preparation process, etc., and achieve convenient large-scale The effect of industrial production, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Therefore, according to the second aspect of the present invention, the present invention provides a method for preparing a fracturing proppant, the preparation method comprising: grinding the composition, then mixing with water and granulating into balls, wherein the combination The product is the fracturing proppant composition described in the first aspect of the present invention.

[0030] According to the preparation method of the present invention, relative to 100 parts by weight of the composition, the amount of water used is preferably 10-30 parts by weight.

Embodiment approach

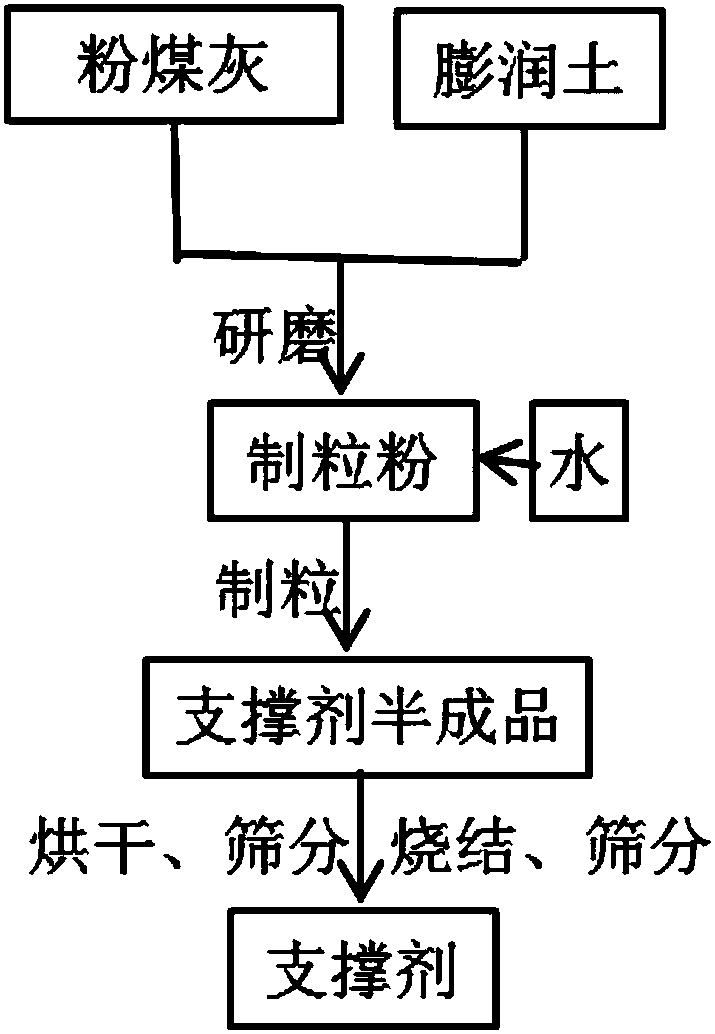

[0031] According to a specific embodiment, such as figure 1 Shown, this preparation method comprises the following steps:

[0032] (1) adding the fly ash and the bentonite to a grinder for grinding to obtain raw material powder;

[0033] (2) adding the raw material powder and water into a ball forming machine to granulate into balls to obtain a proppant semi-finished product;

[0034] (3) Drying, screening, sintering and re-screening the semi-finished proppant in sequence to obtain the fracturing proppant.

[0035] In step (1), preferably, the grinding makes the median particle size of the raw material powder less than 325 mesh. The present invention has no particular limitation on the grinding machine, which may be a conventional choice for grinding fracturing proppant raw materials, such as one or more selected from Raymond mill, ball mill, jet mill, stirring mill and sand mill. The grinding time is usually 1-5 hours.

[0036]In step (2), preferably the granulation into ...

Embodiment 1-13

[0052] 1) Add fly ash and bentonite (total consumption is 10kg) into a planetary ball mill and grind to obtain raw material powder;

[0053] 2) First add part of the raw material powder and water to the ball forming machine to granulate until the cue ball is formed, then repeat the steps of adding raw material powder and water to make the cue ball grow continuously until the spherical particles grow to an average particle size of 18 Order-30 order, obtain semi-finished proppant (the total consumption of water is 2kg);

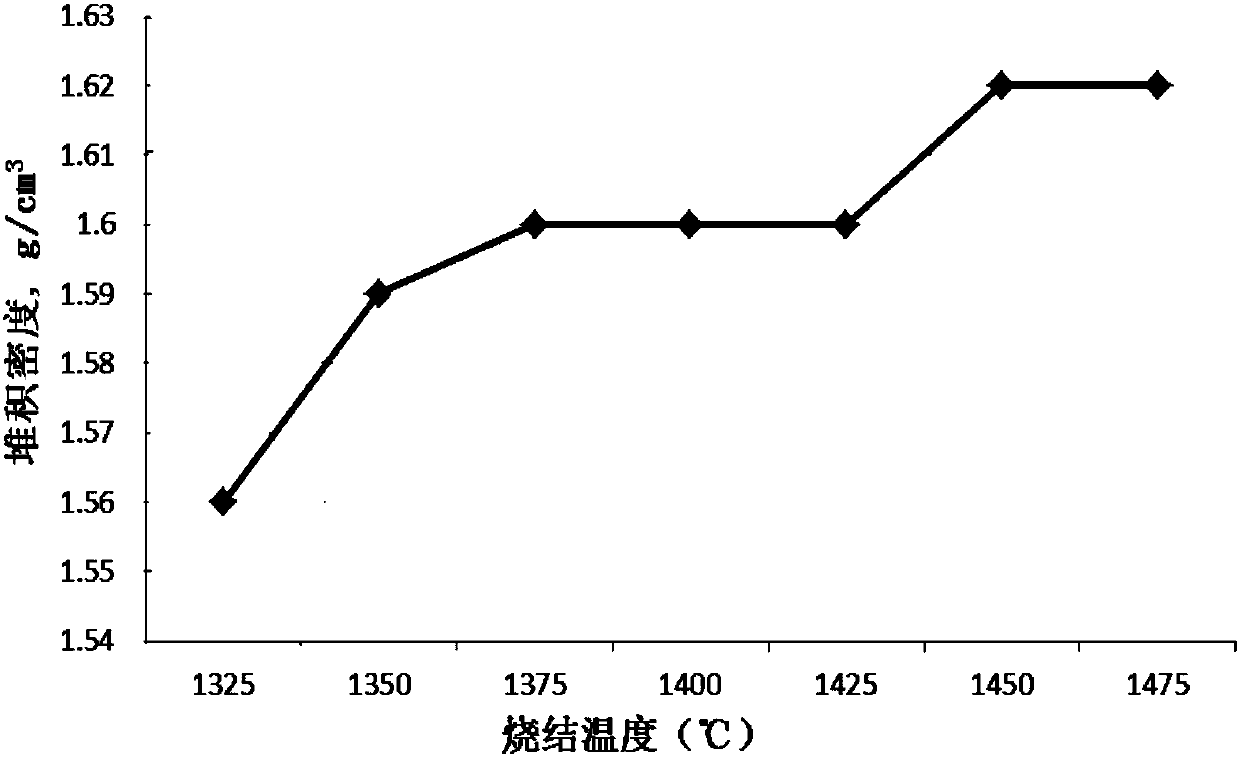

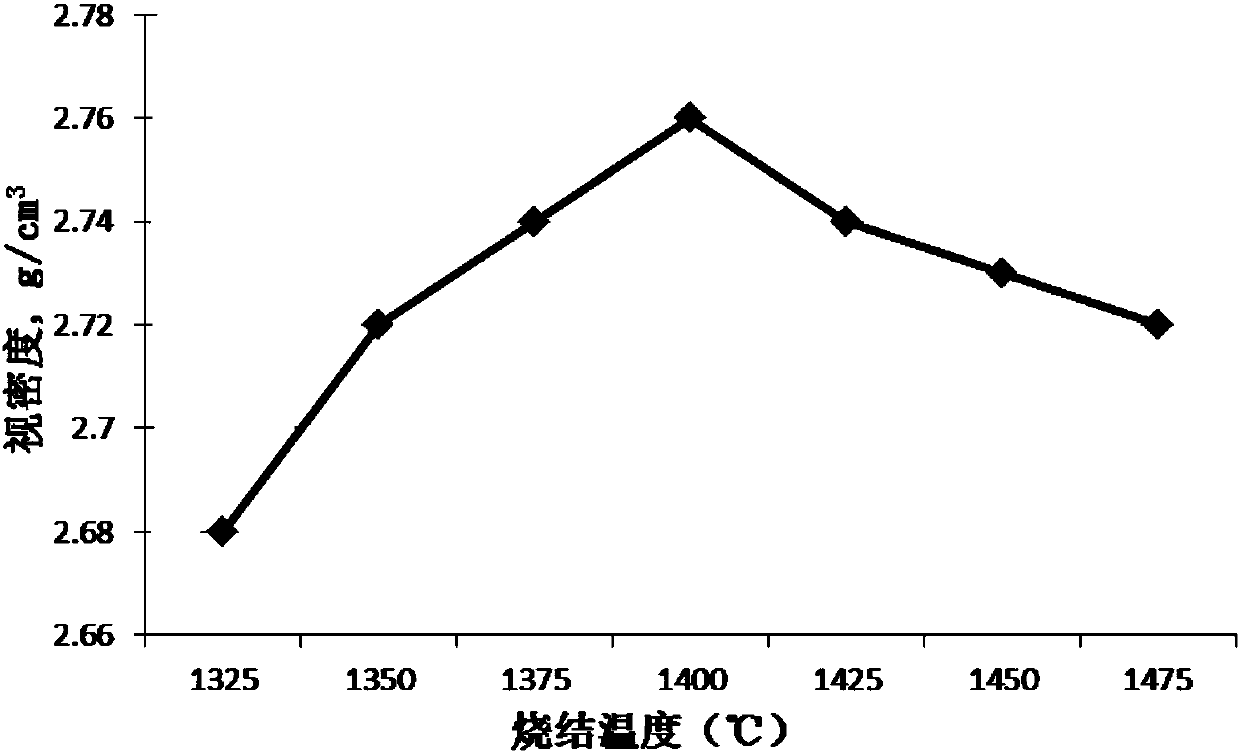

[0054] 3) Dry the semi-finished proppant in an oven at 100°C for 4 hours, and then sieve through 18-mesh and 30-mesh sieves to obtain semi-finished particles with particle sizes below 18 mesh and above 30 mesh, and then put the semi-finished particles into Sintered in a muffle furnace, then cooled naturally, and screened through 20-mesh and 40-mesh sieves to obtain 20 / 40-mesh fracturing proppant. The compositions and proportions of the components provided in E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com