Light and porous sludge ceramisite and preparation method thereof

A sludge ceramsite, lightweight technology, applied to ceramic products, clay products, and other household appliances, can solve the problems of light weight and strength, achieve good void ratio, simple preparation method, and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

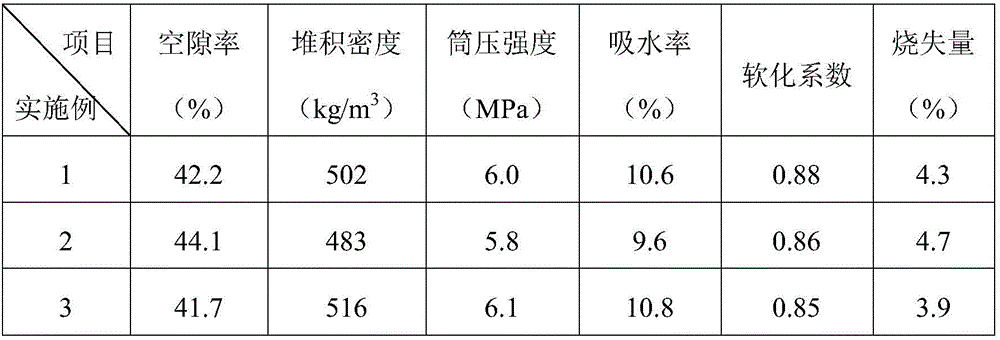

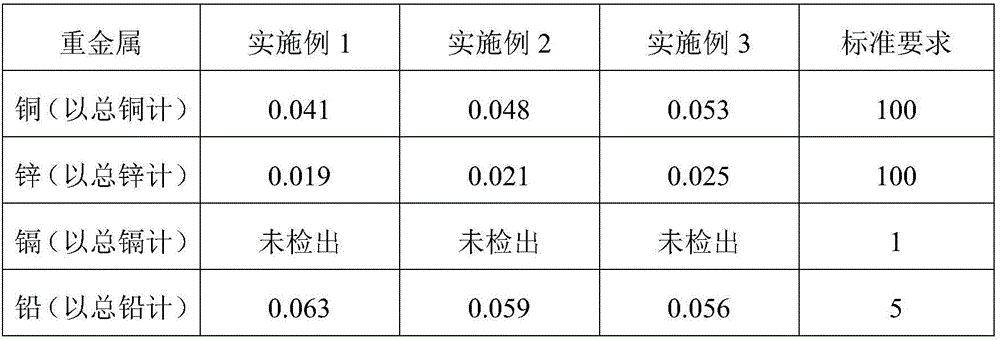

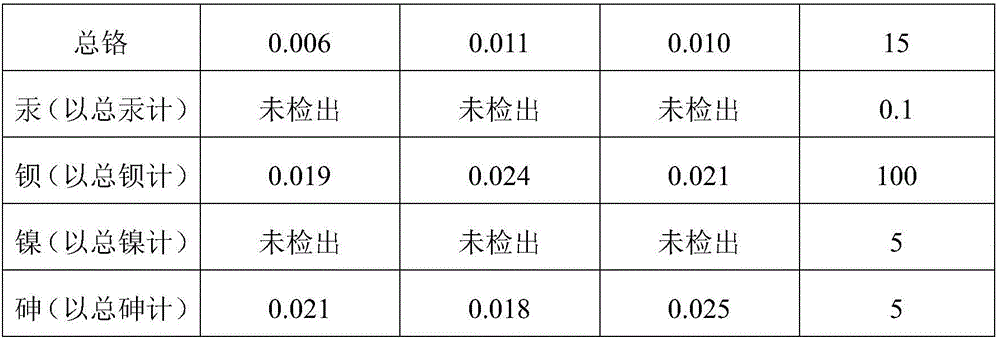

Examples

Embodiment 1

[0024] The lightweight porous sludge ceramsite of the present embodiment comprises the following raw materials in parts by weight: 10 parts of sawdust, 25 parts of fly ash, 5 parts of silica fume, 40 parts of sludge, 10 parts of quicklime, 20 parts of red mudstone, 1 part of phosphogypsum and 8 parts of magnesite.

[0025] The preparation method of the lightweight porous sludge ceramsite of the present embodiment may further comprise the steps:

[0026] (1) magnesite, red mudstone and sawdust are pulverized respectively, and cross 200 mesh sieves;

[0027] (2) Dewater the sludge to reduce the water content of the sludge to 25%; then add fly ash, silica fume, quicklime, phosphogypsum and crushed and sieved sawdust, magnesite and red mudstone, and mix well , compressed into granules;

[0028] (3) aging the particles in step (2) for 24 hours at room temperature;

[0029] (4) Raise the temperature to 180°C at a rate of 5°C / min, hold for 60 minutes, then raise the temperature to...

Embodiment 2

[0031] The lightweight porous sludge ceramsite of the present embodiment comprises the following raw materials in parts by weight: 20 parts of sawdust, 30 parts of fly ash, 8 parts of silica fume, 35 parts of sludge, 12 parts of quicklime, 30 parts of red mudstone, 3 parts of desulfurized gypsum and 10 parts of magnesite.

[0032] The preparation method of the lightweight porous sludge ceramsite of the present embodiment may further comprise the steps:

[0033] (1) magnesite, red mudstone and sawdust are pulverized respectively, and cross 200 mesh sieves;

[0034] (2) Dewater the sludge to reduce the water content of the sludge to 30%; then add fly ash, silica fume, quicklime, desulfurized gypsum, crushed and sieved sawdust, magnesite and red mudstone, and mix well , compressed into granules;

[0035] (3) aging the particles in step (2) for 25 hours at room temperature;

[0036] (4) Raise the temperature to 220°C at a rate of 10°C / min, hold for 30 minutes, then raise the te...

Embodiment 3

[0038] The lightweight porous sludge ceramsite of the present embodiment comprises the following raw materials in parts by weight: 25 parts of sawdust, 20 parts of fly ash, 10 parts of silica fume, 30 parts of sludge, 15 parts of quicklime, 25 parts of red mudstone, Phosphogypsum 5 parts and magnesite 5 parts.

[0039] The preparation method of the lightweight porous sludge ceramsite of the present embodiment may further comprise the steps:

[0040] (1) magnesite, red mudstone and sawdust are pulverized respectively, and cross 200 mesh sieves;

[0041] (2) Dewater the sludge to reduce the water content of the sludge to 30%; then add fly ash, silica fume, quicklime, phosphogypsum, crushed and sieved sawdust, magnesite and red mudstone, and mix well , compressed into granules;

[0042] (3) aging the granules in step (2) for 30 hours at room temperature;

[0043] (4) Raise the temperature to 200°C at a rate of 8°C / min, hold for 45 minutes, then raise the temperature to 650°C a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com