Method for casting mould core and shell integrated ceramic

A ceramic casting mold and manufacturing method technology, applied in the field of investment casting, can solve problems such as poor stability, assembly error, positioning error, etc., achieve high mutual position accuracy, high mutual position accuracy, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

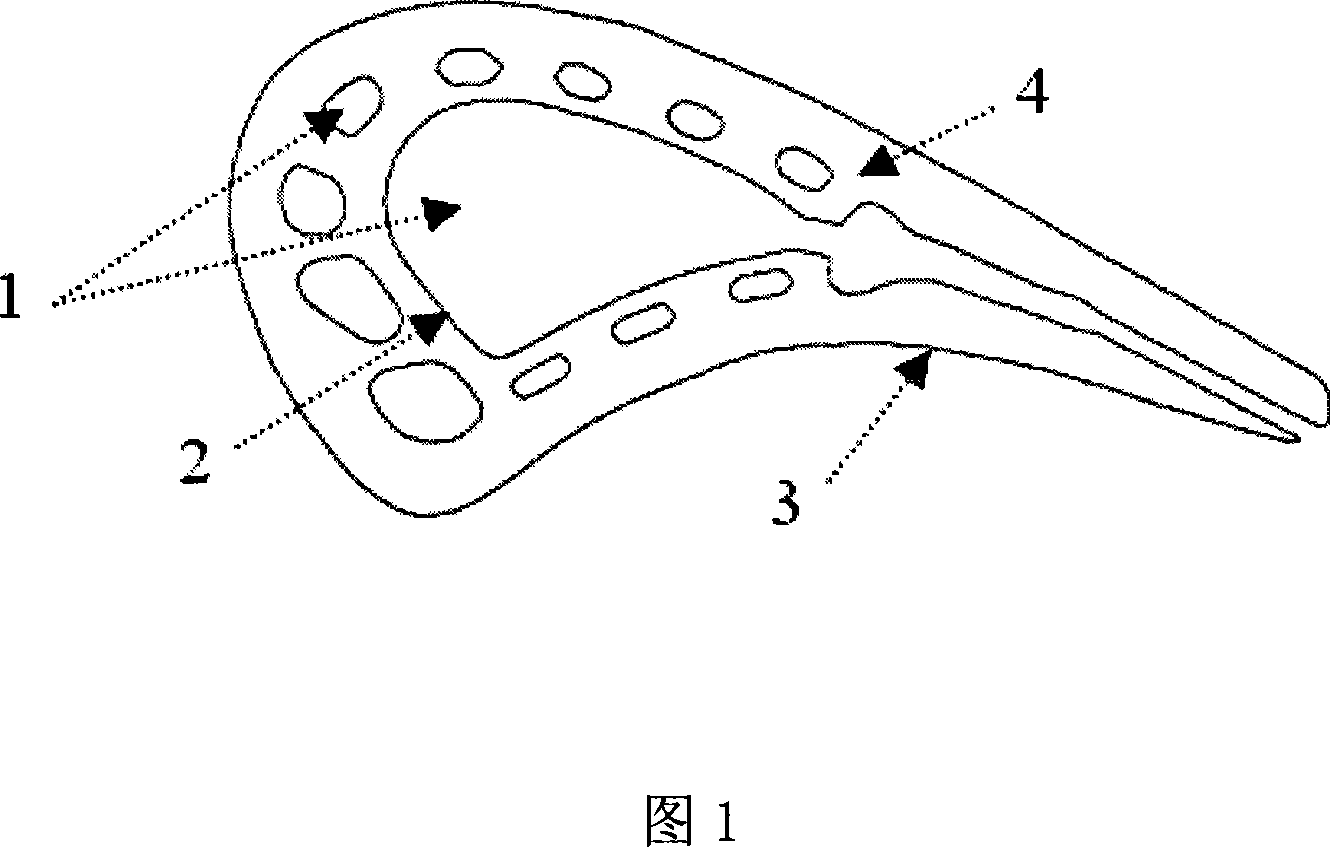

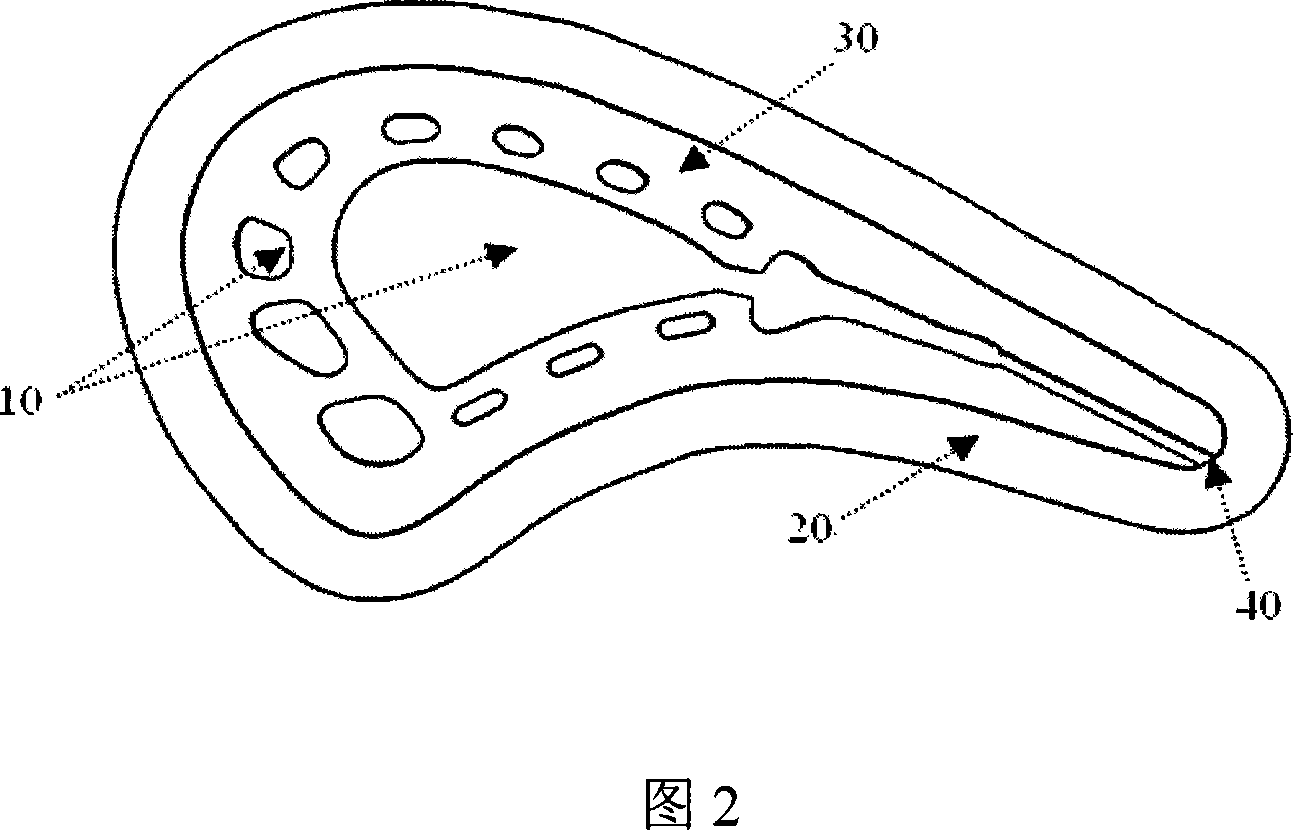

[0015] According to the manufacturing method of the core and shell integrated ceramic casting mold of the present invention, the casting produced is a thin-walled structural part, has a complex inner cavity structure, and can form at least one cooling channel.

[0016] A set of resin molds is prepared, the resin mold is designed with a part for ensuring the uniform wall thickness of the ceramic shell, and the ceramic mold is designed with a sprue and a riser for casting high-temperature metal. The ceramic slurry is injected into the resin mold under a certain pressure, and the value of the grouting pressure is in the range of 0.01MPa to 0.1MPa. After solidification, drying, degreasing and roasting, the integrated ceramic core and shell are obtained, which provide casting molds for casting production with complex inner cavity structure and thin wall. When the core and the shell are formed, they are naturally integrated to form a ceramic mold, and the oxide is ceramicized to a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com