Manufacturing method of archaized brick transparent glaze

A manufacturing method and transparent glaze technology, which is applied in the field of antique brick transparent glaze manufacturing, can solve the problems of the inability to combine the glazed surface with the green body, the complicated manufacturing process of the transparent glaze, and the inability to meet customer needs, etc., and achieve the elimination of product Blank glaze separation, more expressive patterns, and delicate product patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

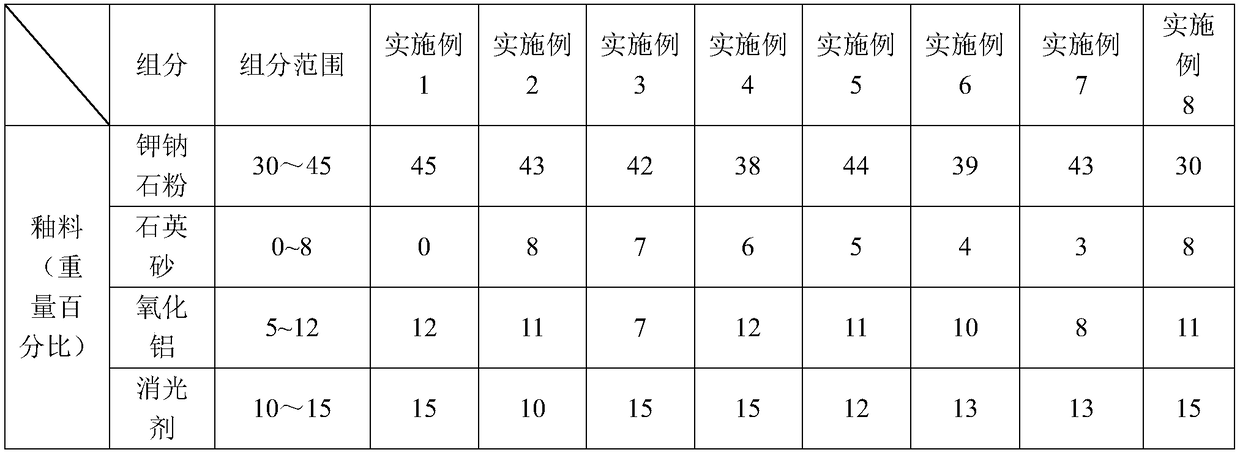

[0051] Below in conjunction with specific embodiment the present invention is described in further detail: Table 1

[0052]

[0053]

[0054]

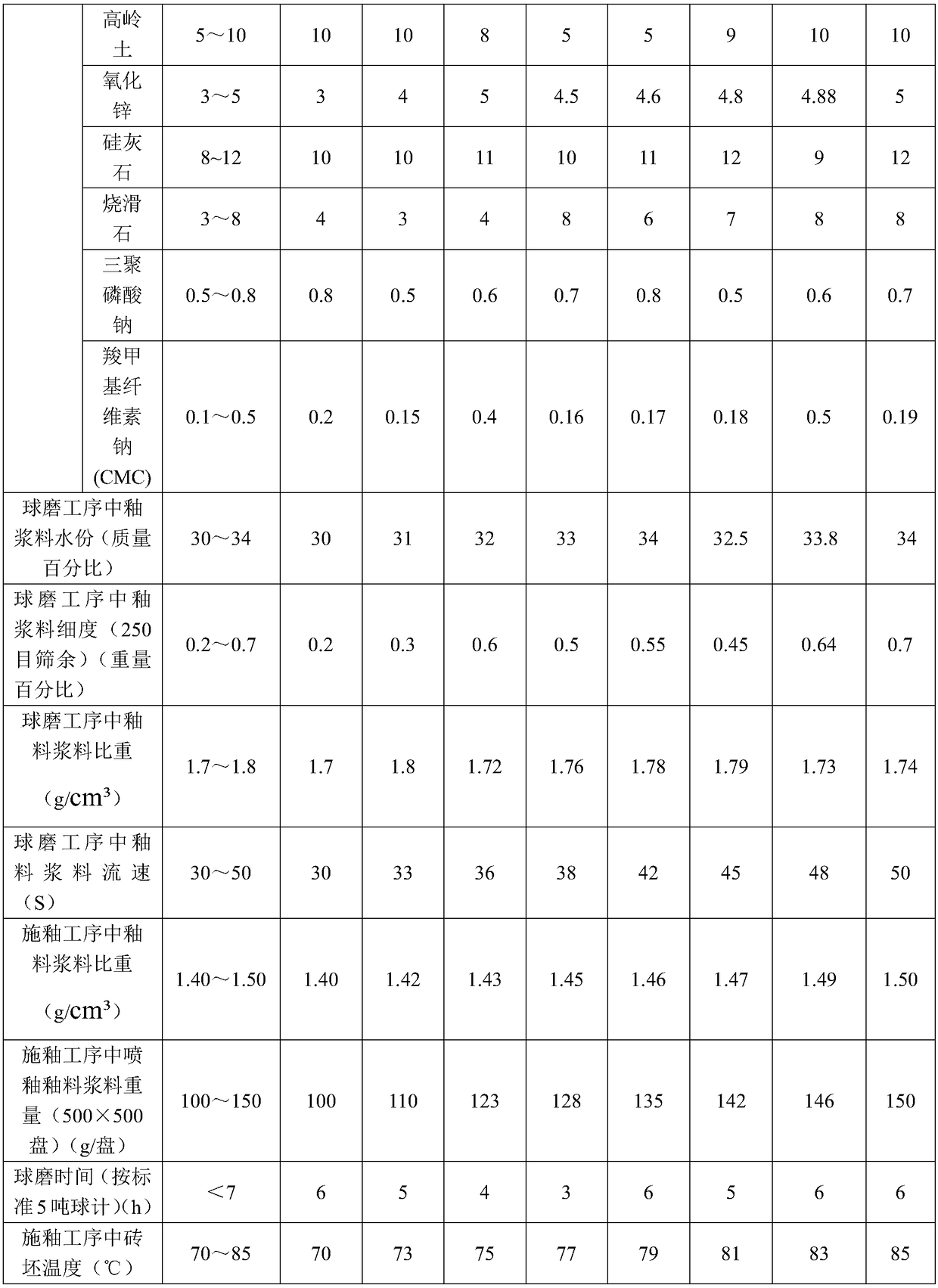

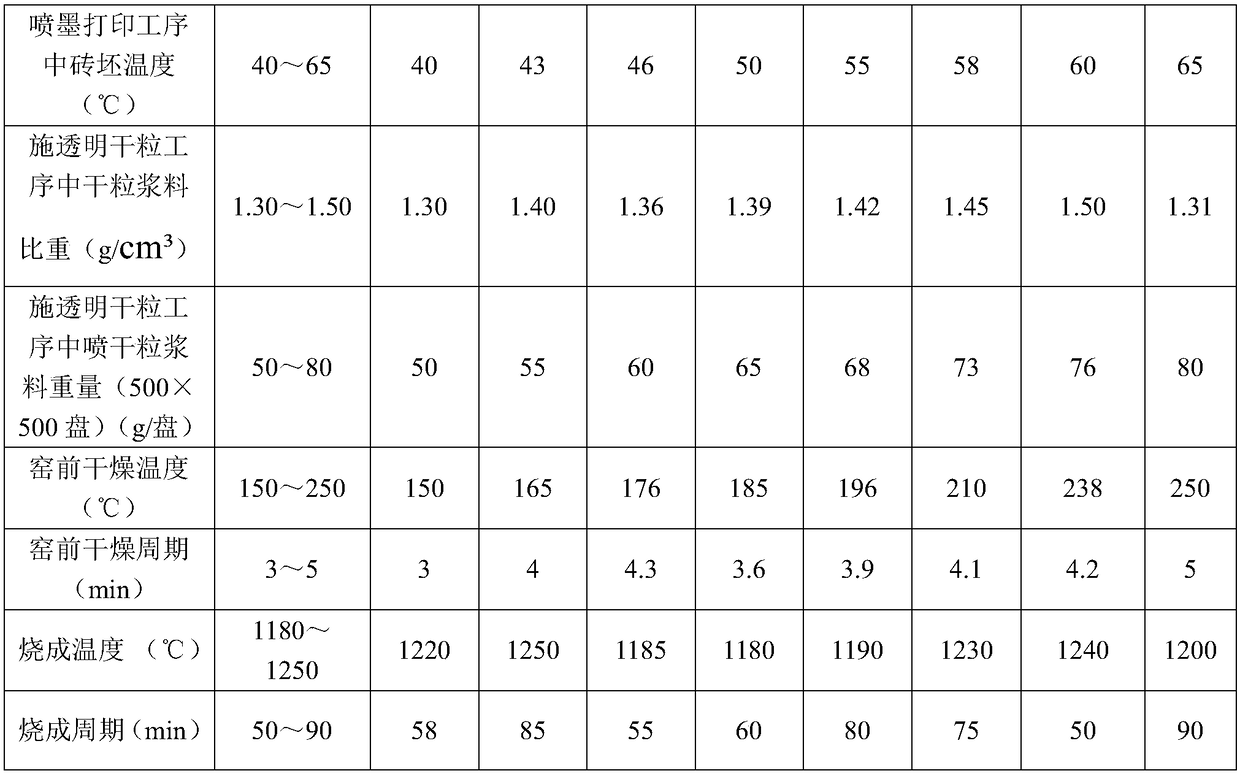

[0055] Table 2

[0056]

[0057] The technological process of the manufacturing method of a kind of antique brick transparent glaze comprises:

[0058] Material selection→debugging formula→batching→ball milling→iron removal→sieving to remove impurities→glaze slurry stale→drawing glaze line→adjusting glaze slurry process parameters→inkjet printing→drying in front of kiln→high temperature firing→semi-finished product process →sorting→packaging→warehousing;

[0059] Adding a glaze cabinet to apply a transparent glaze process between the process of adjusting the process parameters of the glaze slurry and the process of inkjet printing;

[0060] Between the ink-jet printing process and the pre-kiln drying process, a second application of transparent glaze (or transparent dry particles) by the glaze cabinet is added.

[0061] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com