Formula of body mud of high-glass-phase stoneware and preparation process of body mud

A technology of preparation process and mud material, which is applied in the field of preparation process of ceramic materials, can solve problems such as high production cost, long sintering time, and large environmental pollution, and achieve the effect of reducing the probability of product deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

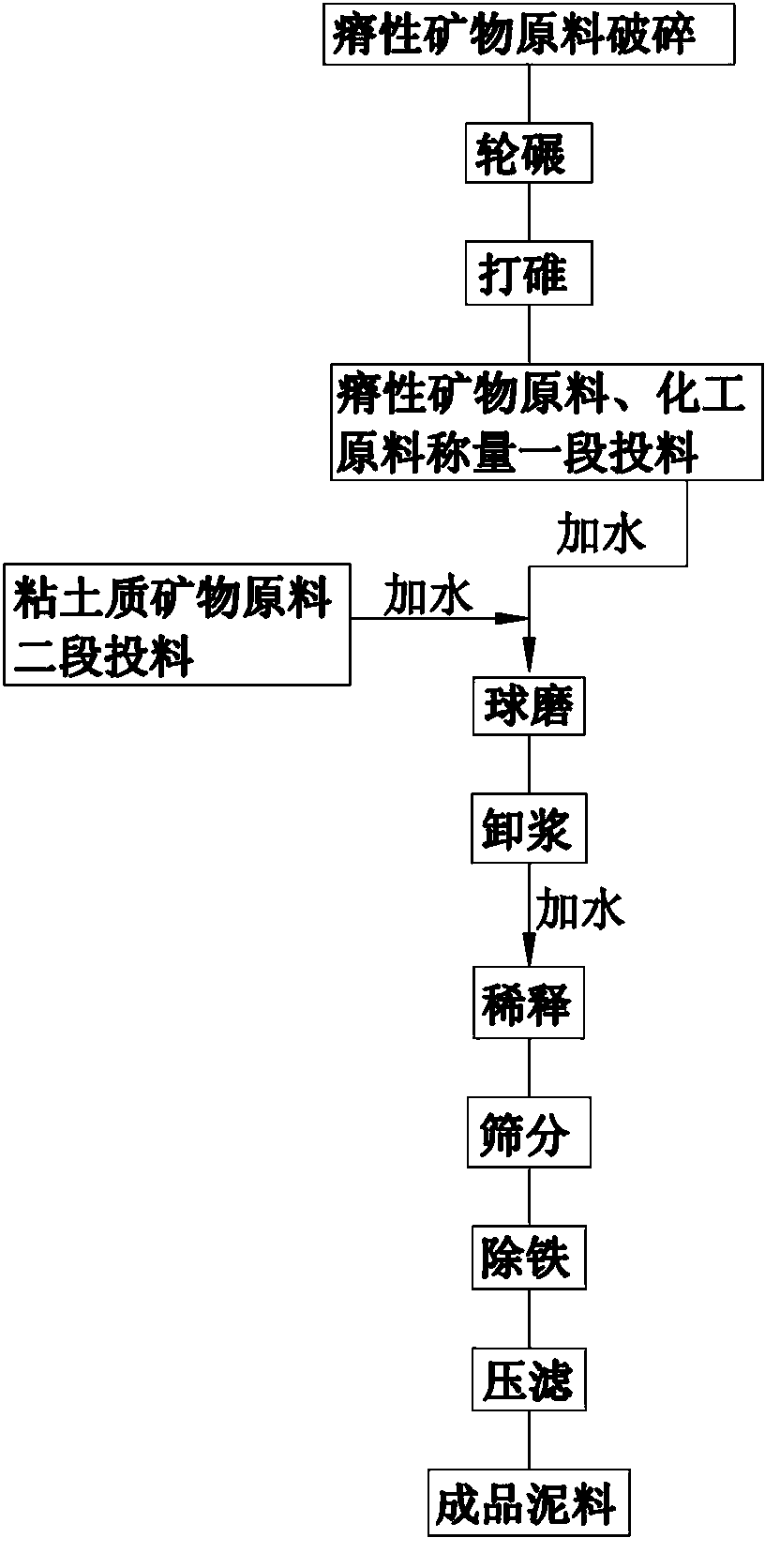

Method used

Image

Examples

Embodiment approach 1

[0020] This embodiment is a preferred embodiment. The body mud formula of high-vitreous stoneware porcelain, the formula of the body mud mainly includes: 62.0-65.0% SiO2 according to the mass percentage of chemical components 2 , 11.~13.0% Al 2 o 3 , 9.0-11% MgO, 1.3-1.6% CaO, 1.5-2.0% K 2 O, 0.7~1.0% Na 2 O, 3.0-4.0% BaO and 4.0-5.5% loss on ignition. The above chemical components can be formulated by introducing the following mineral raw materials and chemical raw materials: quartz, porcelain stone, kaolin, bentonite, burnt talc, raw talc, potassium feldspar, albite feldspar, barium feldspar, alumina, barium carbonate, etc. Among them, kaolin and bentonite are clay mineral raw materials, quartz, porcelain stone, burnt talc, raw talc, potassium feldspar, albite, barium feldspar, etc. are barren mineral raw materials, and alumina and barium carbonate are chemical raw materials. In addition, the formula also includes Fe2O3, TiO2, MnO and other metal oxide polluting impurit...

Embodiment approach 2

[0028] This embodiment is a preferred embodiment. The body mud formula of high-vitreous stoneware porcelain, the formula of the body mud includes: 67.0% SiO2 according to the mass percentage of chemical components 2 , 10.5% Al 2 o 3 , 9.5% MgO, 1.0% CaO, 2.5% K 2 O, 0.5% Na 2 O, 3.5% BaO, 4.9% loss on ignition. The above chemical components can be formulated by introducing the following mineral raw materials and chemical raw materials: quartz, porcelain stone, kaolin, bentonite, burnt talc, raw talc, potassium feldspar, albite feldspar, barium feldspar, alumina, barium carbonate, etc. . In addition, the formula also includes Fe2O3, TiO2, MnO and other metal oxide polluting impurity components brought by mineral raw material companions.

[0029] The preparation process of high-vitreous phase stoneware body mud, which includes the following steps carried out in sequence:

[0030] a. Ingredients weighing: match, combine and weigh the barren mineral raw materials, clay mine...

Embodiment approach 3

[0033] The body mud formula of high-vitreous stoneware porcelain, the formula of the body mud includes: 63.0% SiO2 according to the mass percentage of chemical components 2 , 13.5% Al 2 o 3 , 8.0% MgO, 2.0% CaO, 1.5% K 2 O, 2.0% Na 2 O, 4.0% BaO, 5.5% loss on ignition. The above chemical components can be formulated by introducing the following mineral raw materials and chemical raw materials: quartz, porcelain stone, kaolin, bentonite, burnt talc, raw talc, potassium feldspar, albite feldspar, barium feldspar, alumina, barium carbonate, etc. . In addition, the formula also includes Fe2O3, TiO2, MnO and other metal oxide polluting impurity components brought by mineral raw material companions.

[0034] The preparation process of high-vitreous phase stoneware body mud, which includes the following steps carried out in sequence:

[0035] a. Batch weighing: match, combine and accurately weigh and feed the barren mineral raw materials, clay mineral raw materials and chemical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com