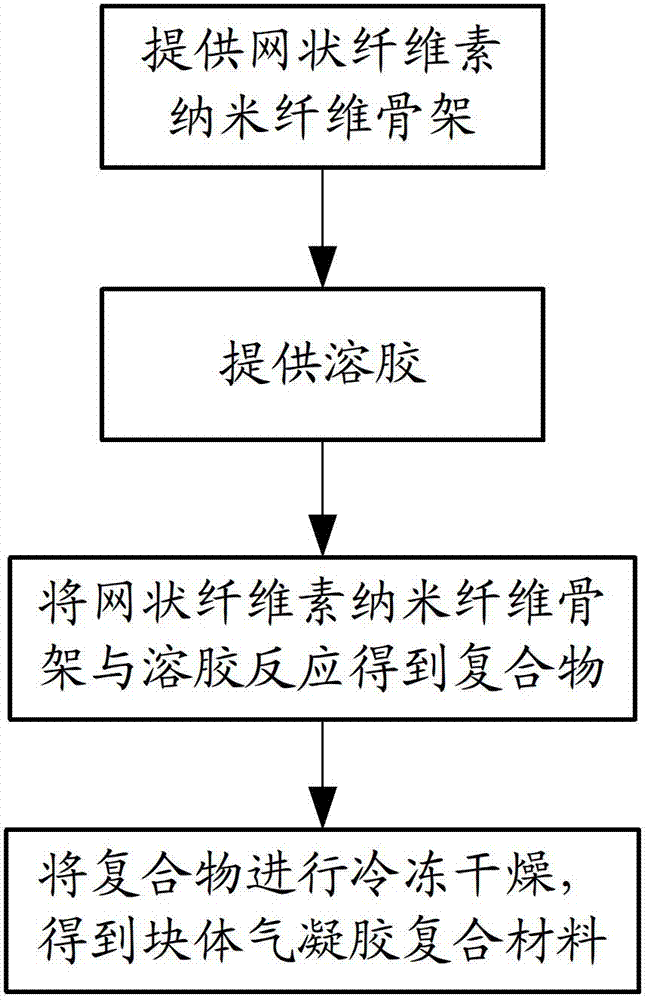

Block aerogel composite material and preparation method thereof

A composite material and aerogel technology, applied in the field of bulk aerogel composite materials and their preparation, can solve the problems of breaking or separating from fibers, falling off of aerogel fragments, and high hardness of the composite, so as to improve mechanical properties. , The effect of reducing preparation cost and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0087] In the preparation of the organic sol, those skilled in the art can select or adjust the ratio of each component according to the actual situation, so as to obtain the desired organic sol.

[0088] According to an embodiment of the present invention, the organic sol precursor used is resorcinol and formaldehyde, and the basic catalyst is sodium carbonate, wherein the molar ratio of resorcinol: formaldehyde: water: sodium carbonate can be 1:1.5 ~2.5:50~1500:0.001~0.1, preferably 1:1.8~2.2:50~1000:0.002~0.1, preferably 1:1.8~2.0:150~500:0.005~0.05.

[0089] When the sol is a metal oxide sol, the specific operation steps may include: uniformly mixing the metal oxide sol precursor with alcohol and water, adding an acidic catalyst and stirring to obtain the metal oxide sol.

[0090] It should be understood that the materials used in the preparation process of the metal oxide sol are not particularly limited, and the precursor of the organic sol includes butyl titanate, titan...

Embodiment 1

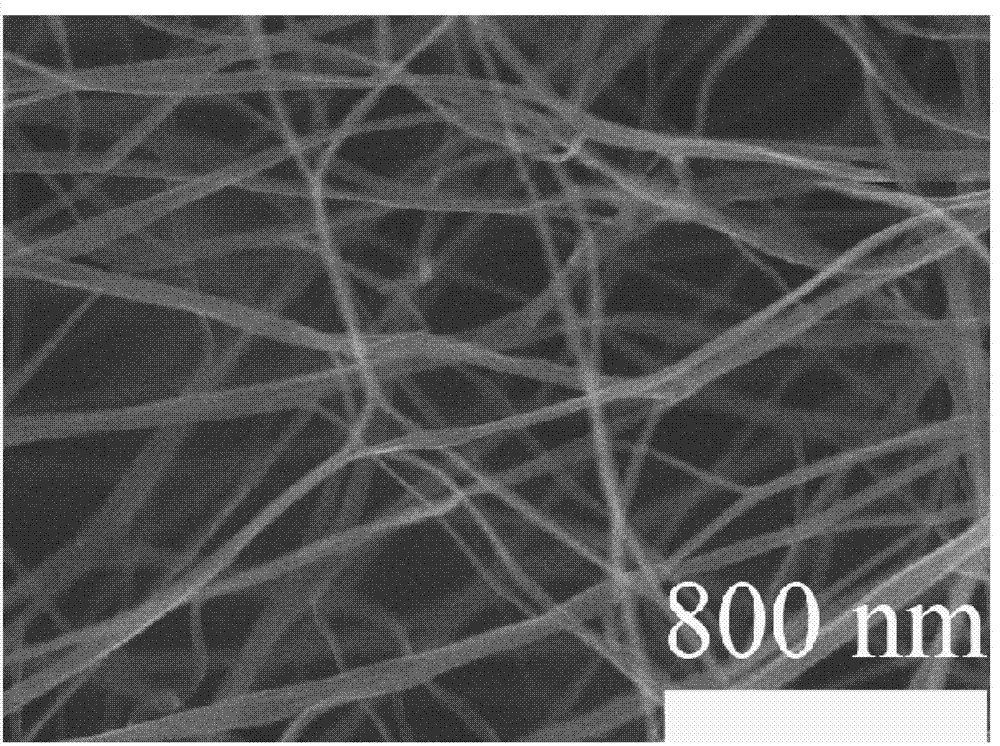

[0113] Inoculate the pre-cultivated seed culture solution of Acetobacter xylinum into 12L of Acetobacter xylinum fermentation medium with 10% inoculum, shake fully, and culture at a constant temperature of 30°C for 15 days to obtain cellulose hydrogel . Among them, the Acetobacter xylinum fermentation broth contains 2% glucose, 0.5% peptone, 0.5% yeast powder, 0.27% disodium hydrogen phosphate pentahydrate, 0.115% citric acid-hydrate, pH 6.0, and high temperature sterilization for 20 minutes.

[0114] The cellulose hydrogel fermented by microorganisms was placed in 5% NaOH aqueous solution at 90°C for 10 hours, and then placed in deionized water at 85°C for 15 hours, during which the deionized water was replaced 3 times, and then the volume ratio was 1: The mixed solution of 1 tert-butanol and deionized water was subjected to solvent replacement at 60°C for 10 hours, during which the mixed solution was replaced twice, and then freeze-dried until the sample was completely dry t...

Embodiment 2

[0119] Inoculate the pre-cultivated seed culture solution of Acetobacter xylinum into 10L of Acetobacter xylinum fermentation medium with 12% inoculum, shake fully, and culture at a constant temperature of 30°C for 20 days to obtain cellulose hydrogel . Among them, the Acetobacter xylinum fermentation broth contains 4% glucose, 0.8% peptone, 0.5% yeast powder, 0.35% disodium hydrogen phosphate pentahydrate, 0.115% citric acid-hydrate, pH is 6.2, and is sterilized at high temperature for 20 minutes.

[0120] The cellulose hydrogel fermented by microorganisms was placed in 6% NaOH aqueous solution and treated at 90°C for 8 hours, and then placed in deionized water at 85°C for 15 hours. During this period, the deionized water was replaced 3 times, and then the volume ratio was 1: The mixed solution of 1 tert-butanol and deionized water was subjected to solvent replacement at 58°C for 10 hours, during which the mixed solution was replaced twice, and then freeze-dried until the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com