High-strength glass fiber composition

A glass composition and glass fiber technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of high liquidus temperature, increase production cost, poisoning of platinum bushings, etc. The effect of reducing the pressure of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] After the alumina after removing impurities is fully calcined at about 1100 ° C, the moisture content is controlled within 1.0%, the iron content is not about 0.15%, and the particle size is controlled at 200 meshes;

[0024] The blast furnace slag that has been quenched at a high temperature above 1300°C from the steelmaking blast furnace is processed by the iron removal system, and the iron content is detected and controlled to be less than or equal to 0.3%. While grinding, a certain amount of oxidizing compound is added according to the redox property of the blast furnace slag, such as sulfate (about 1 ton of blast furnace slag is added with 1 to 10Kg of oxidizing compound).

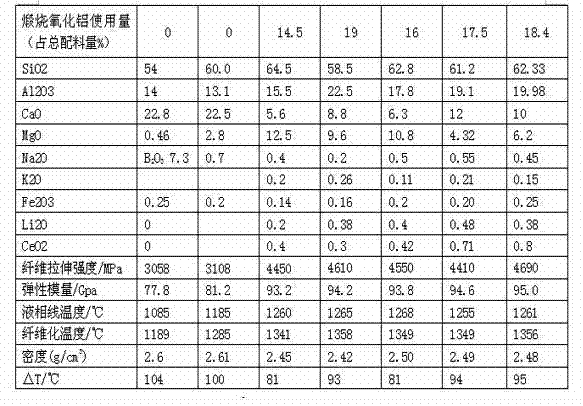

[0025] Weigh 150Kg of calcined alumina, 100Kg of ground blast furnace slag, detect its composition, add 130Kg of magnesia, 30Kg of quicklime, 620Kg of silica sand and other mineral raw materials to prepare about 1 ton of batch materials as shown in Table 1, and calculate according to the formula ...

Embodiment 2

[0026] Example 2, take by weighing 225Kg calcined alumina, 80Kg ground blast furnace slag as in Example 1, detect its composition, calculate according to formula, add mineral raw materials such as 98Kg magnesium oxide 55Kg unslaked lime, 559Kg silica sand and be mixed with composition as table 1 About 1 ton of batch material is melted in the tank kiln to melt and draw glass fibers. The glass fiberization temperature is 1358°C, △T 93°C, elastic modulus is 94.2Gpa, and tensile strength is 4610Mpa.

Embodiment 3

[0027] Example 3, take by weighing 175Kg calcined alumina, 60Kg ground blast furnace slag as in Example 1, detect its composition, calculate according to formula, add mineral raw materials such as 122Kg magnesium oxide 27Kg unslaked lime, 600Kg silica sand and be mixed with composition as table 1 About 1 ton of batch material is melted in the tank kiln to melt and draw glass fibers. The glass fiberization temperature is 1349°C, △T 81°C, the elastic modulus is 93.8Gpa, and the tensile strength is 4550Mpa.

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com