Macroscopic-microcosmic-nanometer hierarchical mechanical compatible bone restoration and preparation thereof

A bone restoration and hierarchical structure technology, applied in the field of biomedical engineering, can solve the problems of bone tissue anatomical morphology and mechanical properties mismatch, and achieve excellent biological performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

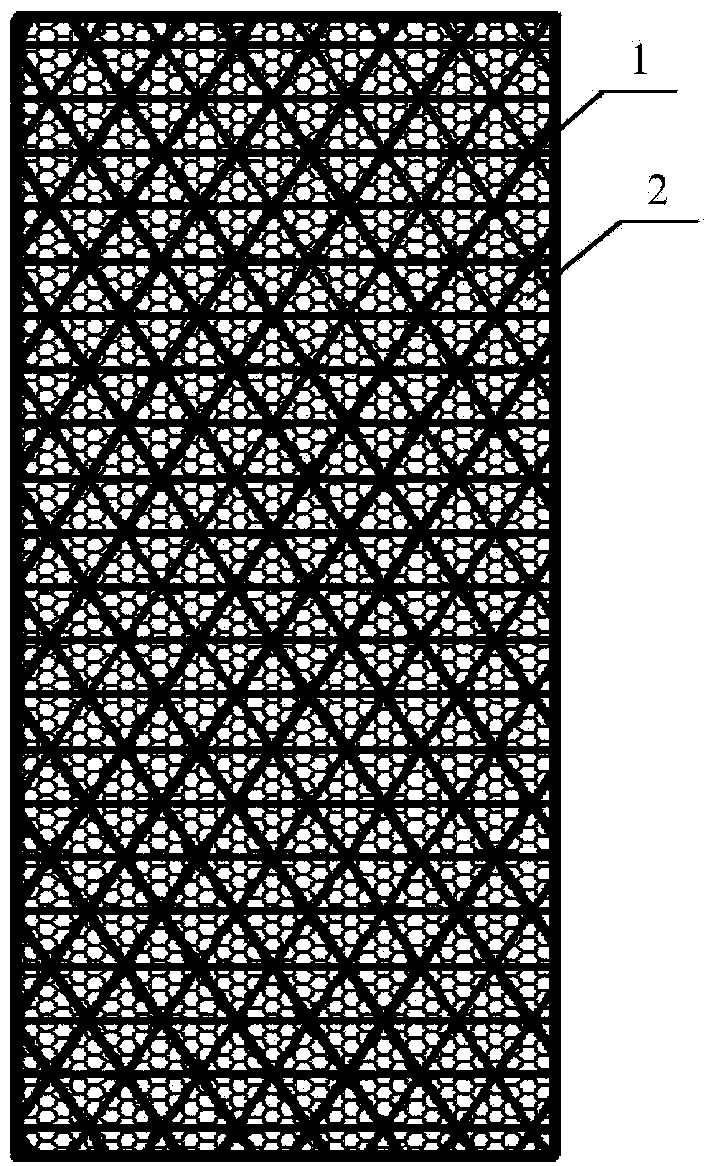

[0034] First, according to the CT data of the patient, use Mimics software to reconstruct the three-dimensional bone model of the patient's defect site; secondly, according to the mechanical properties of the bone tissue at the defect site and actual clinical needs, use commercial CAD software, such as: Unigraphics, Pro / E, Catia, etc. , design the CAD model of the macroporous metal structure, the macroscopic pore size is 800 microns, the porosity is 70%, the compressive strength is 120MPa, and the elastic modulus is 10GPa; the designed macroporous metal structure CAD model and the patient's defect site The three-dimensional model of the bone is subjected to Boolean operations to form a CAD model of the macroporous metal structure whose anatomical shape is consistent with the bone model of the patient's defect; according to the CAD model of the macroporous metal structure whose anatomical shape is consistent with the bone model of the patient's defect, The metal powder is used a...

Embodiment 2

[0036]First, according to the patient's MRI data, use Mimics software to reconstruct the three-dimensional bone model of the patient's defect site; secondly, according to the mechanical properties of the bone tissue at the defect site and actual clinical needs, use commercial CAD software, such as: Unigraphics, Pro / E, Catia, etc. , design the CAD model of the macroporous metal structure, the macroscopic pore size is 300 microns, the porosity is 90%, the compressive strength is 60MPa, and the elastic modulus is 0.5GPa; the designed macroporous metal structure CAD model and the patient's defect Perform Boolean operations on the 3D bone model of the site to form a CAD model of the macroporous metal structure whose anatomical shape is consistent with the bone model of the patient's defect site; Using metal powder as raw material, using laser melting molding technology, the manufacture of macroporous metal structure 1 is completed; silk fibroin is prepared into a solution through an...

Embodiment 3

[0038] First, according to the CT data of the patient, use Mimics software to reconstruct the three-dimensional bone model of the patient's defect site; secondly, according to the mechanical properties of the bone tissue at the defect site and actual clinical needs, use commercial CAD software, such as: Unigraphics, Pro / E, Catia, etc. , design the CAD model of the macroporous metal structure, the macroscopic pore size is 1500 microns, the porosity is 50%, the compressive strength is 300MPa, and the elastic modulus is 30GPa; the designed macroporous metal structure CAD model and the patient's defect site The three-dimensional model of the bone is subjected to Boolean operations to form a CAD model of the macroporous metal structure whose anatomical shape is consistent with the bone model of the patient's defect; according to the CAD model of the macroporous metal structure whose anatomical shape is consistent with the bone model of the patient's defect, The metal powder is used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com