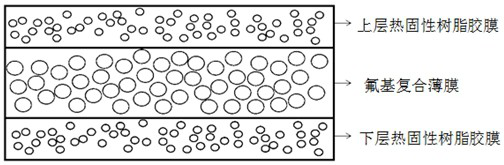

Low-loss high-uniformity bonding sheet and preparation method of multilayer microwave plate

A bonding sheet and uniformity technology, applied in chemical instruments and methods, film/sheet adhesives, non-polymer adhesive additives, etc., can solve wave distortion, low uniformity, and large thermal expansion coefficient and other issues, to achieve the effect of reducing the thermal expansion coefficient, expanding the scope of application, and increasing flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

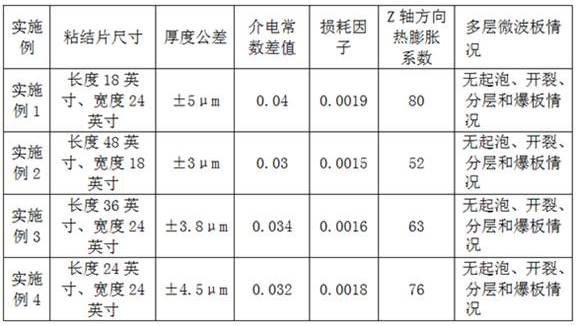

Embodiment 1

[0049] Embodiment 1, the material components of Embodiment 1 are all parts by weight.

[0050] The components of the fluorine-based composite film of the bonding sheet are composed of 70 parts of polytetrafluoroethylene, 85 parts of filler I spherical SiO with an average particle size of 0.5 μm 2 composition, the coupling agent added at the same time is 3 parts of phenyltrimethoxysilane, and the surfactant is 5 parts of octylphenol polyoxyethylene ether. The thickness of the upper thermosetting resin film and the lower thermosetting resin film of the adhesive sheet are equal, both are 5 μm, and the components are 100 parts of thermosetting resin polybutadiene, 5 parts of initiator dicumyl peroxide, 65 parts of average particle size Filler II ellipsoidal SiO with a diameter of 10 μm 2 , 20 parts of thermoplastic elastomer styrene-butadiene-styrene copolymer, 1 part of flame retardant alkyl phosphate and 1 part of zinc dialkyldithiophosphate antioxidant, 1 part of plasticizer o...

Embodiment 2

[0062] Embodiment 2, the material components of embodiment 2 are all parts by weight.

[0063] The components of the fluorine-based composite film of the bonding sheet are composed of 80 parts of a copolymer of perfluoropropyl perfluorovinyl ether and polytetrafluoroethylene, and 87 parts of filler I ellipsoid Al with an average particle size of 8 μm. 2 o 3 composition, the coupling agent added at the same time is 3.5 parts of aminopropyltrimethoxysilane, and the surfactant is 7 parts of nonylphenol polyoxyethylene ether. The thickness of the upper thermosetting resin film and the lower thermosetting resin film of the bonding sheet are different, respectively 20 μm and 30 μm, and the components are 140 parts of thermosetting resin modified polybutadiene, 7 parts of initiator diisopropyl hydroperoxide Benzene, 100 parts of filler II irregular shape perovskite ceramic powder with an average particle size of 13 μm, 40 parts of thermoplastic elastomer styrene-butadiene rubber, 3 ...

Embodiment 3

[0075] Embodiment 3, the material components of embodiment 3 are all parts by weight.

[0076] The components of the fluorine-based composite film of the bonding sheet are composed of 85 parts of polyvinylidene fluoride, 88 parts of filler I with an average particle size of 30 μm, and irregularly shaped TiO 2composition, the coupling agent added at the same time is 4 parts of methyltrimethoxysilane, and the surfactant is 9 parts of octylphenol polyoxyethylene ether. The thickness of the upper layer thermosetting resin film and the lower layer thermosetting resin film of the bonding sheet are equal to 35 μm, and the components are 180 parts of thermosetting resin polyisoprene, 9 parts of initiator di-tert-butyl peroxide, 150 parts Filler II spherical mullite ceramic powder with an average particle size of 15 μm, 60 parts of thermoplastic elastomer ethylene propylene rubber, 6 parts of flame retardant triazine and its derivatives, 6 parts of antioxidant alkyl phenothiazine, 6 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com