Nano-silica/poly(conjugated diene) composite emulsion and preparation method thereof

A technology of nano-silica and polyconjugated diene, which is applied in the field of preparation of functional emulsions, can solve the problems of narrow PSN molecular weight distribution, difficulty in processing and application, and quality loss, and achieves simple and easy control of the preparation process, low cost, and improved The effect of overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] a) Surface functional modification of nano-silica: Weigh 120g of nano-silica and dry it in an oven for use, then mix it with 1200g of toluene and then ultrasonically disperse it fully. hours, then filtered, washed, and vacuum-dried.

[0035] b) Preparation of functional emulsion

[0036] The first step is the preparation of monomer pre-emulsion. 1,200 g of 1,3-butadiene, 120 g of sodium dodecylbenzenesulfonate, 1,800 g of deionized water, 12 g of sodium hydroxide, and 2.4 g of potassium persulfate were mixed and pre-emulsified for 20 minutes to prepare a pre-emulsion.

[0037] In the second step, the functional emulsion is prepared with the modified nano-silica as the core. Take 3.6g of nano-silica modified by surface functionalization and add it to a reactor containing 60g sodium dodecylbenzenesulfonate and 480g deionized water, stir and heat up to 60°C, and then take 313g monomer pre-emulsion Add it into the reactor, control the temperature of the reactor at 60°C, ...

Embodiment 2

[0039] a) According to the method disclosed in "Journal of Radiation Research and Radiation Technology", Volume 25, No. 5, "Study on Surface Modification of Nano-Silicon Dioxide and Radiation-Initiated Grafting GMA" in 2007, prepare surface-functionalized modified nano-silicon dioxide Method: Weigh 6g of nano-silicon dioxide and dry it in an oven at 50°C for 5 hours, add the dried nano-silicon dioxide to an aqueous solution in which 96g of coupling agent MPS is dissolved, and disperse it ultrasonically for 1 hour. After dispersion, the mixture was stirred at 110°C for 8h. After filtration, the modified silicon dioxide was washed with toluene, and the obtained product was vacuum filtered, extracted by Soxhlet, and finally dried in an oven.

[0040] b) Preparation of functional emulsion

[0041] The first step is the preparation of monomer pre-emulsion. 1200 g of isoprene, 72 g of sodium lauryl sulfate, 1200 g of deionized water, 6 g of ammonia water, and 9.6 g of ammonium per...

Embodiment 3

[0044] a) Surface functional modification of nano-silica: Weigh 240g of nano-silica and dry it in an oven for use, then mix it with 4800g of xylene and then ultrasonically disperse it fully, add 312g of hydrolyzed VTMS, stir and heat to 93°C for reflux 4 hours, then filtered, washed, and vacuum dried.

[0045] b) Preparation of functional emulsion

[0046] The first step is the preparation of monomer pre-emulsion. Prepare by mixing 1200g of 1,3-pentadiene, 40g of sodium dodecylbenzenesulfonate, 200g of alkylphenol polyoxyethylene ether, 1920g of deionized water, 9.6g of sodium carbonate and 9.8g of sodium persulfate for 30 minutes into a pre-emulsion.

[0047] In the second step, the functional emulsion is prepared with the modified nano-silica as the core. Get 54g of surface-functionalized modified nano-silica and add it to a reactor equipped with 54g fatty acid soap and 456g deionized water, stir and heat up to 68°C, then get 676g monomer pre-emulsion and add it to the re...

PUM

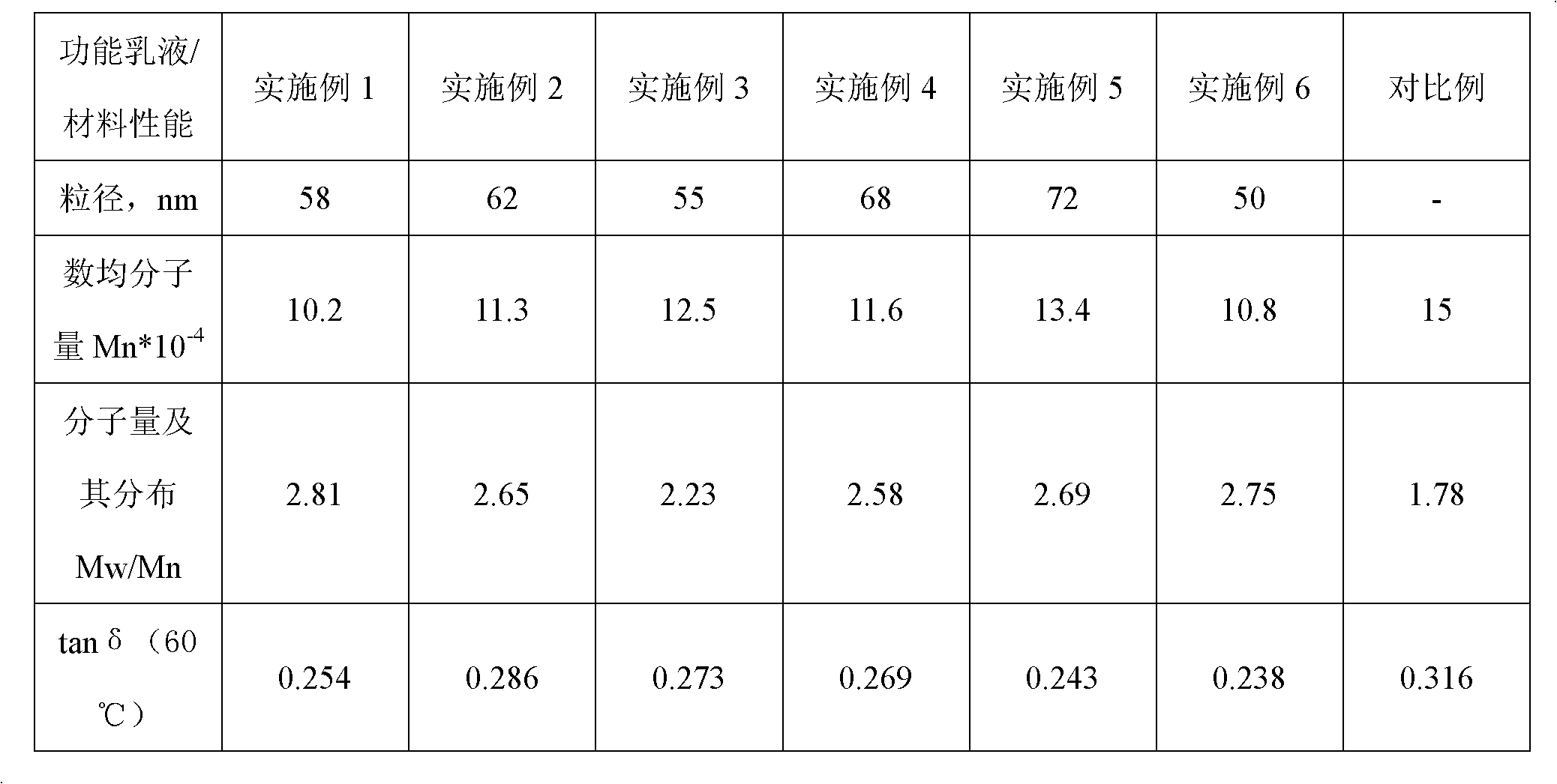

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com