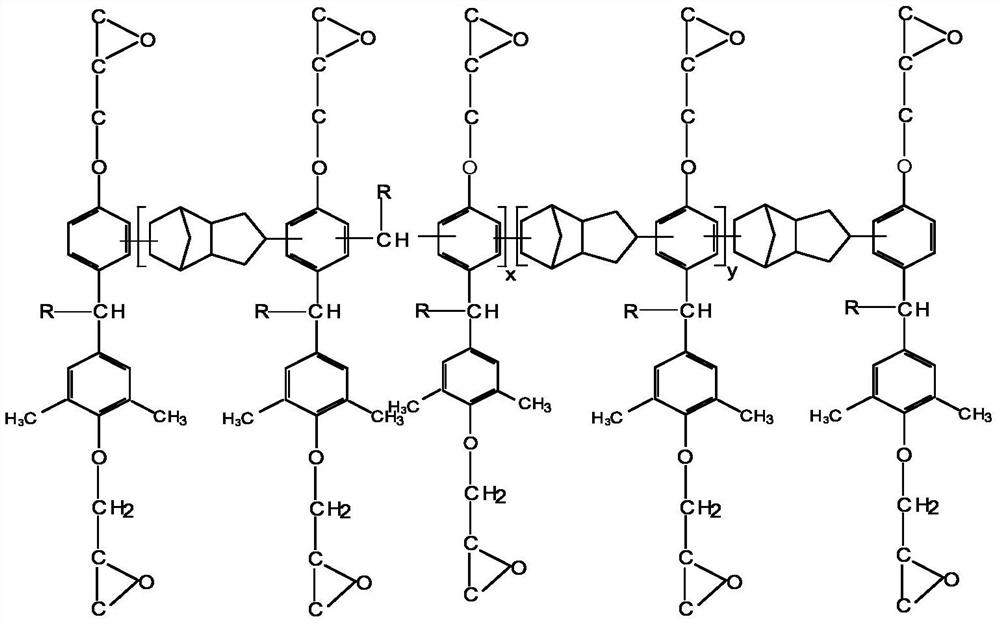

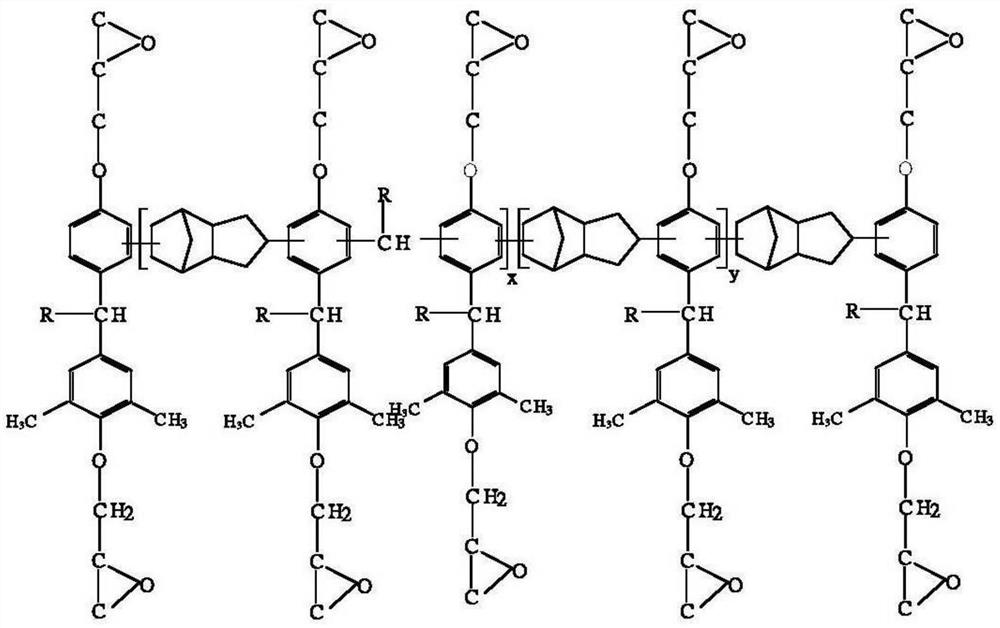

Preparation and Application of Copolymer Epoxy Resin of Dicyclopentadiene-Phenol and 2,6-Dimethylphenol

A technology of dicyclopentadiene and dimethylphenol, applied in synthetic resin layered products, chemical instruments and methods, layered products, etc., can solve the problem of low bridging density, low molecular dipole moment, glass transition temperature Low problems such as low water absorption, excellent electrical properties, and excellent low dielectric constant Dk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example A

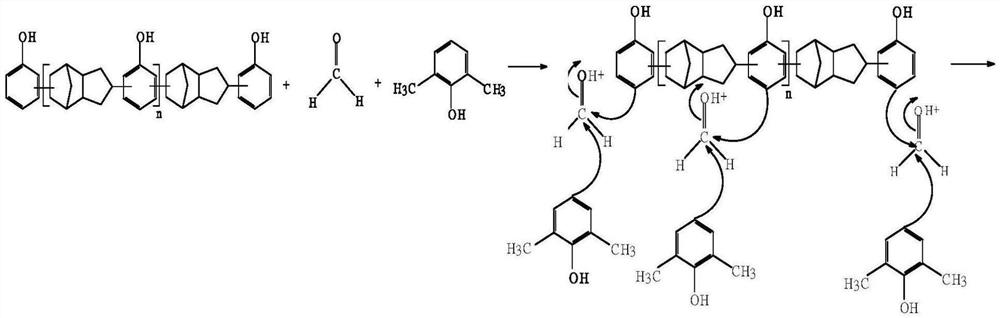

[0032] Synthesis Example A: (Synthesis of Copolymer Epoxy Resin A of Dicyclopentadiene-phenol and 2,6-Dimethylphenol)

[0033] Dicyclopentadiene-phenol resin (NPEH-772L, product name of Nanya Plastics Co., Ltd., softening point 85°C) 170g (1 mole of phenolic hydroxyl group), 170g of 2,6-dimethylphenol, solvent methyl isobutyl ketone (MIBK ) 30g, catalyst methanesulfonic acid MSA 1.7g mixed and heated up to 107°C, then 130g of 23% formaldehyde solution was added dropwise at 107°C for 3.5 hours, and then matured at 107°C for 1Hr. After the reaction, 49.5% NaOH aqueous solution was added 0.8g, neutralize until the pH value = 6-7, raise the temperature to 140°C for dehydration, raise the temperature to 185°C, and slowly reduce the vacuum to 5torr. The temperature and vacuum reached the set value of 185°C×5 torr and maintained for 1 hour. After cooling down and breaking the vacuum, add 550g of methyl isobutyl ketone as a solvent, stir at 80°C for 60 minutes to dissolve, add 50g of...

Synthetic example B

[0036] Synthesis Example B: (Synthesis of Copolymer Epoxy Resin B of Dicyclopentadiene-phenol and 2,6-Dimethylphenol)

[0037] Dicyclopentadiene-phenol resin (NPEH-772H, product name of Nanya Plastics Co., Ltd., softening point 110°C) 180g (1 mole of phenolic hydroxyl group), 170g of 2,6-dimethylphenol, solvent methyl isobutyl ketone (MIBK ) 30g, catalyst methanesulfonic acid MSA 1.7g mixed and heated up to 107°C, then 130g of 23% formaldehyde solution was added dropwise at 107°C for 3.5 hours, and then matured at 107°C for 1Hr. After the reaction, 49.5% NaOH aqueous solution was added 0.8g, neutralize until the pH value = 6-7, raise the temperature to 140°C for dehydration, raise the temperature to 185°C, and slowly reduce the vacuum to 5torr. The temperature and vacuum reached the set value of 185°C×5 torr and maintained for 1 hour. After cooling down and breaking the vacuum, add 550g of methyl isobutyl ketone as a solvent, stir at 80°C for 60 minutes to dissolve, add 50g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com