Coupling agent for carbon black, and preparation method and application thereof

A technology of coupling agent and mercaptosilane coupling agent, which is applied in the field of materials, can solve the problems of tediousness and difficulty in large-scale promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

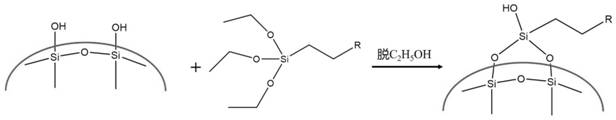

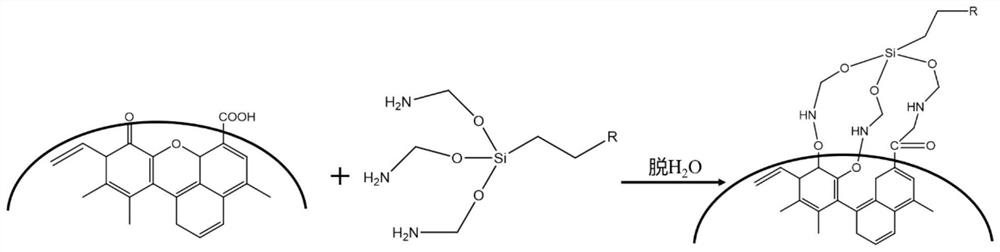

Method used

Image

Examples

Embodiment 1

[0050] 238g γ-mercaptopropyltriethoxysilane, a commercial product produced by BASF, and 89g 4-amino-1-butanol, a commercial product produced by Shanghai Panhong Chemical Technology Co., Ltd., were put into a mixing device and In the 500ml three-necked flask of the distillation device, the molar ratio of feeding is 1:1, no catalyst is added, and the reaction is stirred at a temperature of 120°C. Ethanol is continuously produced under the action of nitrogen, and the reaction lasts for 40 hours. After the reaction, the product was rotary evaporated at 80°C and 50mbar to remove unreacted monomers and small molecules to obtain R 1 for C 4 h 8 , R 2 for C 3 h 6 , n=2, X=1 yellow liquid, ethanol 20.8g, yield 45.2%. The resulting carbon black is named 4-0-M with a coupling agent 1 -KH580.

Embodiment 2

[0052] Put 238g of γ-mercaptopropyltriethoxysilane and 178g of 4-amino-1-butanol into a 1000ml three-necked flask equipped with a stirring device and a distillation device, the molar ratio of feeding: 1:2, and add 12.5g of titanium N-butyl acid was used as a catalyst, and the reaction was stirred at a temperature of 110°C. Under the action of nitrogen, ethanol was continuously produced, and the reaction was completed until no ethanol fraction was produced, and the reaction continued for 6 hours. After the reaction, the product was rotary evaporated at 80°C and 50mbar to remove unreacted monomers and small molecules to obtain R 1 for C 4 h 8 , R 2 for C 3 h 6 , n=2, X=2 yellow liquid, ethanol 91.2g, yield 99.1%. The resulting carbon black is named 4-0-M with a coupling agent 2 -KH580.

Embodiment 3

[0054] Put 238g of γ-mercaptopropyltriethoxysilane and 267g of 4-amino-1-butanol into a 1000ml three-necked flask equipped with a stirring device and a distillation device, and the molar ratio of the feed: 1:3, and add 15.2g of Toluenesulfonic acid was used as a catalyst, and the reaction was stirred at a temperature of 110°C. Under the action of nitrogen, ethanol was continuously produced, and the reaction was completed until no ethanol fraction was produced, and the reaction continued for 12 hours. After the reaction, the product was rotary evaporated at 80°C and 50mbar to remove unreacted monomers and small molecules to obtain R 1 for C 4 h 8 , R 2 for C 3 h 6 , n=2, X=3 yellow liquid, ethanol 129g, yield 93.5%. The resulting carbon black is named 4-0-M with a coupling agent 3 -KH580.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com