Thermosetting polymer

A polymer and thermosetting technology, applied in lamination, layered products, lamination devices, etc., can solve the problem of large signal loss and achieve the effect of low loss factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

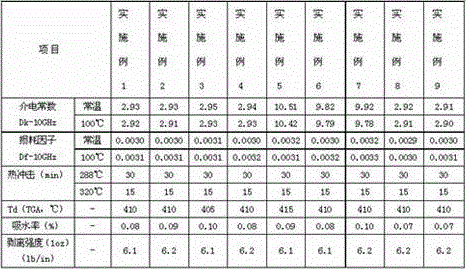

Examples

Embodiment 1

[0018] The formula of the thermosetting polymer in this example is: polyphenylene ether (Resin630) 20g, triallyl isocyanurate (SR533R) 10g, styrene-butadiene-styrene block copolymer (Ricon181) 10g, silicon dioxide (Aerosil R972) 60g.

Embodiment 2

[0020] The formula of the thermosetting polymer in this example is: polyphenylene ether (Resin630) 20g, triallyl isocyanurate (SR533R) 10g, styrene-butadiene-styrene block copolymer (Ricon181) 10g, fused silica (Megasil525) 60g.

Embodiment 3

[0022] The formula of the thermosetting polymer in this example is: polyphenylene ether (Resin630) 10g, triallyl isocyanurate (SR533R) 20g, styrene-butadiene-styrene block copolymer (Ricon181) 20g, fumed silica (Aerosil R972) 60g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| gel time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com