Preparation method of ceramic filled PTFE copper-clad plate

A technology of copper-clad laminates and ceramic fillers, applied in chemical instruments and methods, electronic equipment, applications, etc., can solve problems such as easy settlement, achieve low loss factor, expand application range, and good dip-soldering resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

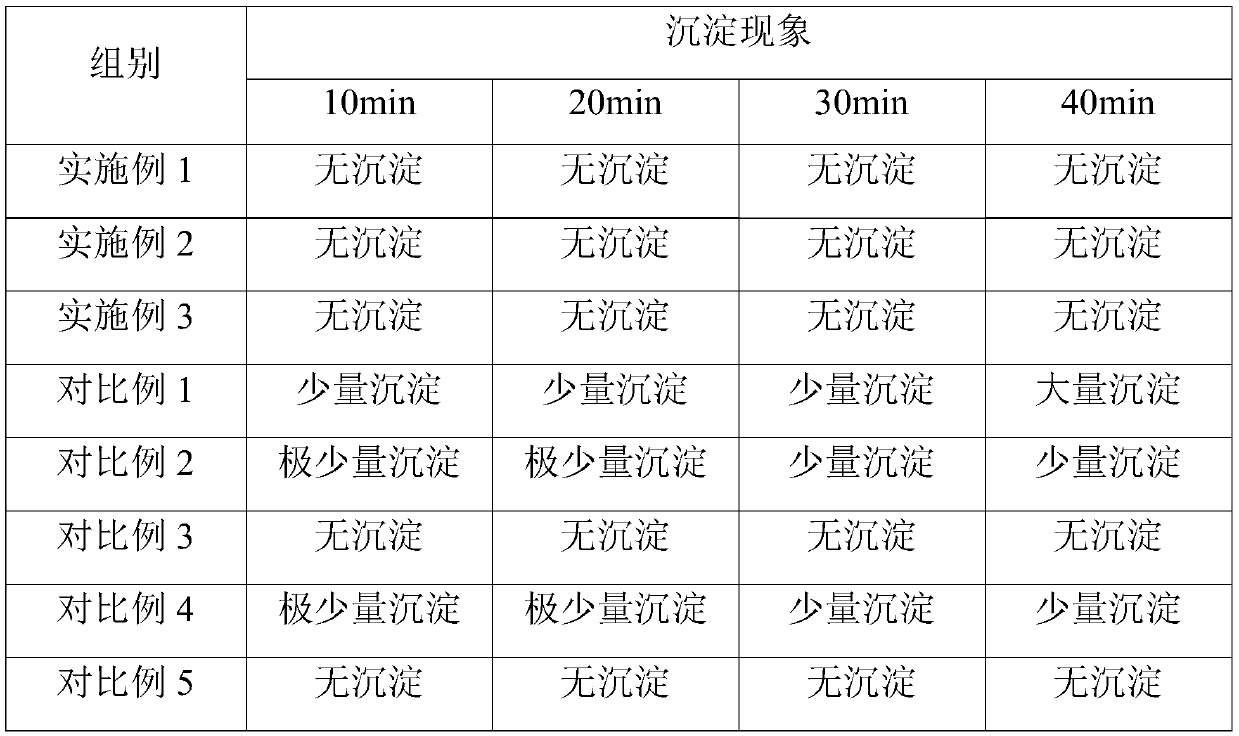

Examples

Embodiment 1

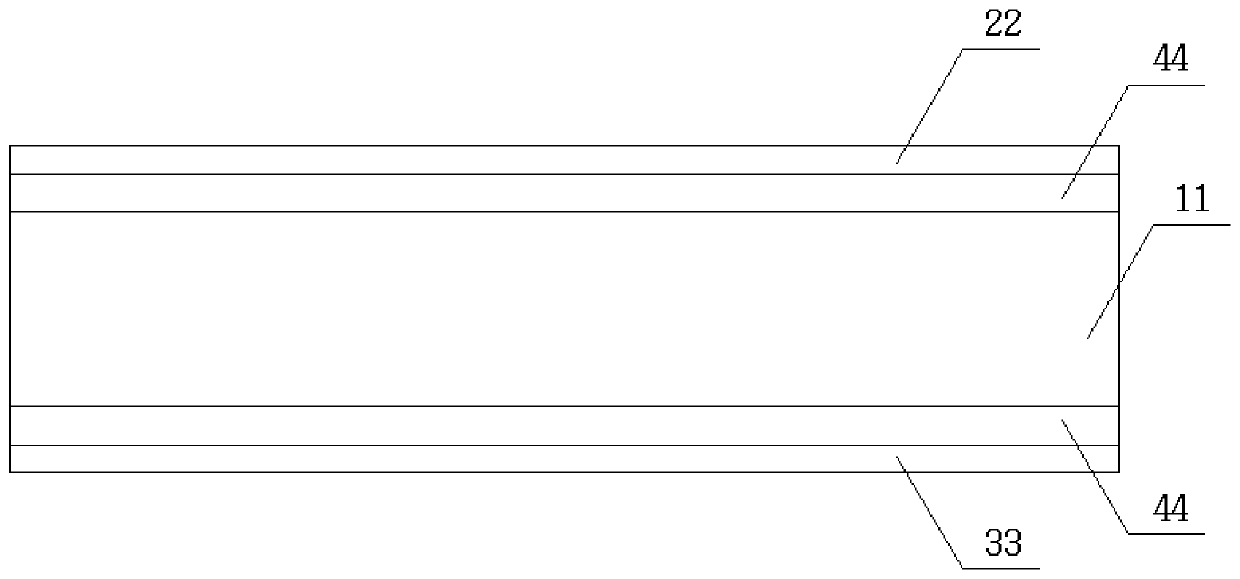

[0034] Embodiment 1, a kind of impregnated fiberglass cloth

[0035] Include the following steps:

[0036] Take 100g of composite ceramic filler, 84g of polytetrafluoroethylene emulsion, 12g of starch and 150g of water (mass ratio: 1:0.84:0.12:1.5) and stir in a stirrer for 60 minutes, let stand, remove air bubbles, and obtain glue; glass fiber cloth Immerse in the glue, and control the amount of glue attached to the glass fiber cloth at 350g / m by the metering roller 2 , and then baked under the conditions of 100°C / 5min+300°C / 5min+380°C / 5min to obtain impregnated glass fiber cloth.

[0037] Wherein, the preparation method of composite ceramic filler is:

[0038] S1) Take 1000g silica powder (particle size range D is 10μm), 25g trehalose fatty acid monoester and 25kg, 30wt% ethanol, carry out ultrasonic dispersion for 3.5h, and then dry under vacuum for 10h to obtain the treated ceramic filler. Take 1000g of the treated ceramic filler and stir in the mixing equipment for 5...

Embodiment 2

[0042] Embodiment 2, a kind of impregnated fiberglass cloth

[0043] Include the following steps:

[0044] Take 100g of composite ceramic filler, 80g of polytetrafluoroethylene emulsion and 150g of water (mass ratio: 1:0.8:1.5) and stir in a stirrer for 55 minutes, let stand, remove air bubbles, and obtain glue; dip glass fiber cloth in the glue, Control the amount of glue attached to the glass fiber cloth at 350g / m by metering rollers 2 , and then baked under the conditions of 100°C / 5min+300°C / 5min+380°C / 5min to obtain impregnated glass fiber cloth.

[0045] Wherein, the preparation method of composite ceramic filler is:

[0046] S1) Take 1000g of glass fiber yarn (particle size range D is 10μm), 25g of trehalose fatty acid monoester and 25kg of 30wt% ethanol for ultrasonic dispersion for 3.5h, and then dry under vacuum for 10h to obtain a treated ceramic filler. Take 1000g of the treated ceramic filler and stir in the mixing equipment for 5min, inject 10g of coupling ag...

Embodiment 3

[0050] Embodiment 3, a kind of impregnated fiberglass cloth

[0051] Include the following steps:

[0052] Take 100g of composite ceramic filler, 75g of polytetrafluoroethylene emulsion, 10g of starch and 150g of water (mass ratio 1:0.75:0.1:1.5) and stir in a stirrer for 55min, let stand, remove air bubbles, and obtain glue; Immerse in the glue, and control the amount of glue attached to the glass fiber cloth at 350g / m by the metering roller 2 , and then baked under the conditions of 100°C / 5min+300°C / 5min+380°C / 5min to obtain impregnated glass fiber cloth.

[0053] Wherein, the preparation method of composite ceramic filler is:

[0054] S1) Take 1000g of silica powder (particle size range D is 10 μm), 25g of trehalose fatty acid monoester and 25kg of 25wt% ethanol for ultrasonic dispersion for 3 hours, and then dry in vacuum for 10 hours to obtain a treated ceramic filler. Take 1000g of the treated ceramic filler and stir in the mixing equipment for 5min, inject 10g of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com