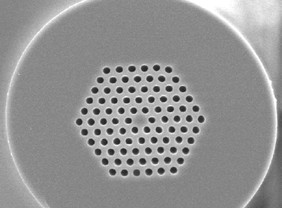

A Fabry-Perot interference sensor based on solid-core photonic crystal fiber and its manufacturing method

A photonic crystal optical fiber and a manufacturing method are applied in the direction of using optical devices to transmit sensing components, coupling of optical waveguides, etc., which can solve the problems of weak measurement signals of sensors, only 5 finenesses, and low measurement accuracy, and are not easy to electromagnetic interference. , high precision, good robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

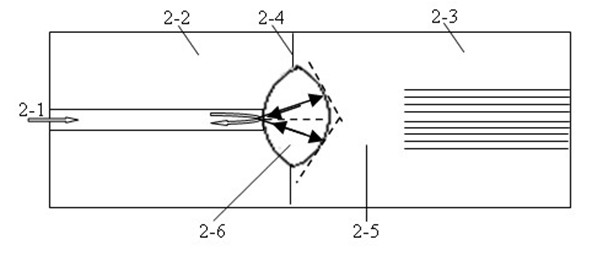

[0051] see figure 2 , the photonic crystal fiber Fabry-Perot interference sensor is composed of an ordinary communication single-mode fiber (SMF) and a solid-core photonic crystal fiber (SM-7.0), and one end of the two fibers is connected with a certain parameter by a fiber fusion splicer Fusion connection. The welding parameters are: gap 50μm, pre-melting time 0.2s, pre-melting current 5mA, welding current 7mA, welding time 650ms, z-axis advance 15μm, additional discharge current 7mA, additional discharge time 650ms. Due to the collapse of the air hole in the cladding of the solid-core photonic crystal fiber, an air cavity is formed between the two fibers to form an F-P cavity. Reflective surface.

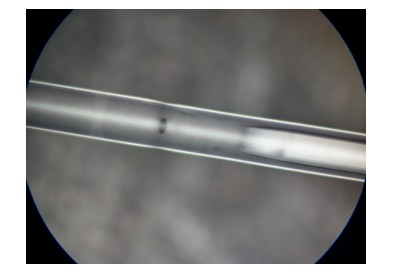

[0052] image 3 It is a photomicrograph of the miniature extrinsic fiber Fabry-Perot interference cavity formed after SMF and SM-7.0 solid-core photonic crystal fiber were arc-discharged four times under the aforementioned fusion conditions. The fabrication method of the phot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cavity length | aaaaa | aaaaa |

| Bandwidth | aaaaa | aaaaa |

| Contrast | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com